Dyeing and finishing process for green chinlon/spandex side stretch fabric

A technology of four-way stretching and craftsmanship, which is applied in the direction of heating/cooling fabric, fabric surface trimming, dyeing method, etc., and can solve the problem of high probability of contact between fabric edge and dyeing liquid, unfavorable energy saving, emission reduction, consumption reduction, and affecting normal production, etc. problem, to achieve the effect of improving dyeing synchronization, reducing color flower phenomenon, and solving edge-to-edge color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A dyeing and finishing process of green brocade / spandex four-way stretch fabric, including the process steps of greige preparation → sewing → refining → preshrinking → dehydration, opening → presetting → warp beam rolling → dyeing → cold water washing → color fixing →washing→unwinding and rolling→softening and shaping→inspection→rolling and packing:

[0034] The refining process is as follows: refining in 8-section continuous refining machine, adding refining degreasing agent 8g / L and chelating dispersant 3g / L in the rolling tank, and controlling the water temperature in the refining tank of 8-section continuous refining machine as 65°C → 92°C ℃→75℃→75℃→60℃→60℃→40℃→40℃, the vehicle speed is 60m / min;

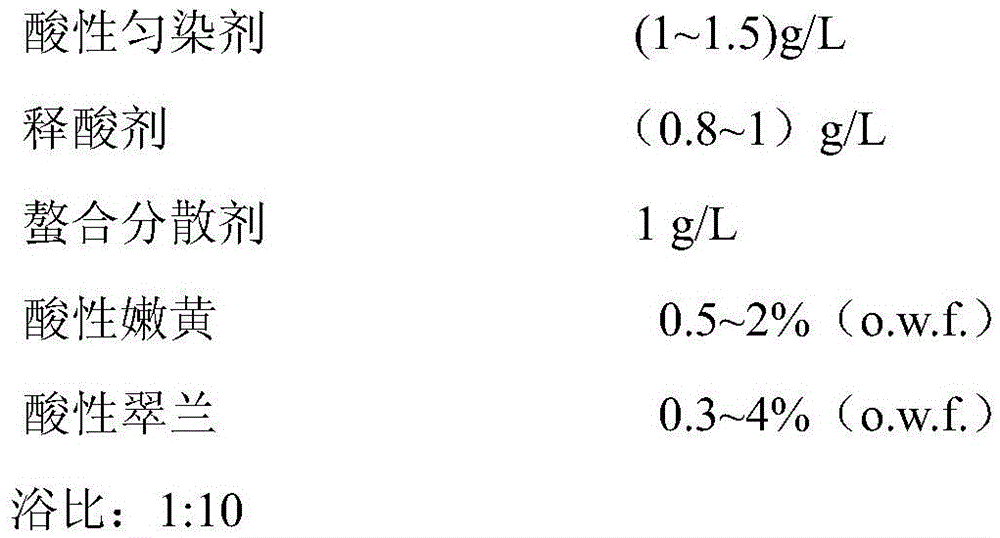

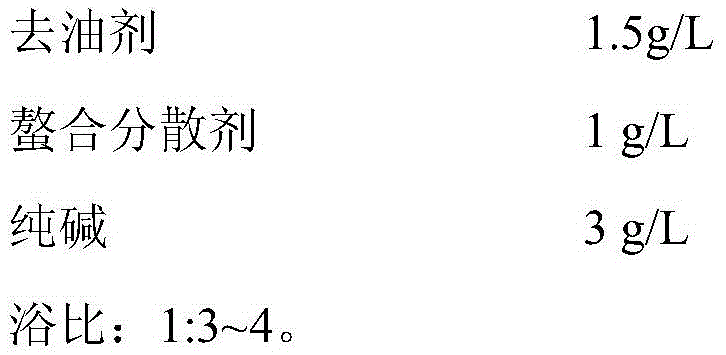

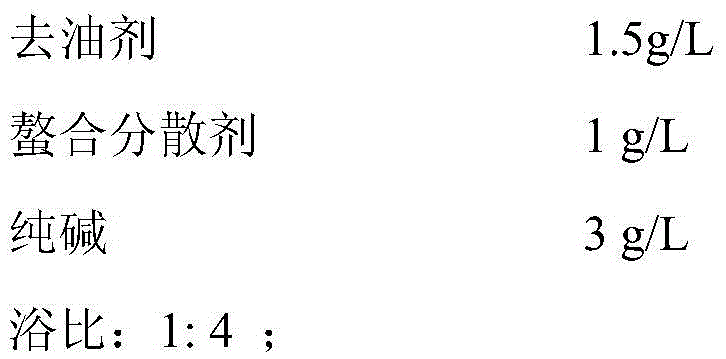

[0035] The pre-shrinking process uses an airflow dyeing machine for pre-shrinking, and heats it for 30 minutes at 90 ° C. The formula is

[0036]

[0037] The temperature of the presetting process is 200°C, and the vehicle speed is 20-30m / min;

[0038] Adopt following...

Embodiment 2

[0047] A dyeing and finishing process of green brocade / spandex four-way stretch fabric, including the process steps of gray fabric preparation → sewing → refining → preshrinking → dehydration, opening → presetting → warp beam rolling → dyeing → cold water washing → color fixing →washing→unwinding and rolling→softening and shaping→inspection→rolling and packing:

[0048] The refining process is as follows: refining in 8-section continuous refiner, adding 8g / L refining degreaser and 3g / L chelating dispersant to the rolling tank, and controlling the water temperature in the refining tank of 8-section continuous refiner as 65°C → 92°C ℃→75℃→75℃→60℃→60℃→40℃→40℃, the vehicle speed is 60m / min.

[0049] The pre-shrinking process uses an airflow dyeing machine for pre-shrinking, and heats it at 90°C for 30 minutes. The formula is:

[0050]

[0051] The temperature of the presetting process is 200°C, and the vehicle speed is 20-30m / min;

[0052] Adopt following dyeing auxiliary for...

Embodiment 3

[0061] A dyeing and finishing process of green brocade / spandex four-way stretch fabric, including the process steps of gray fabric preparation → sewing → refining → preshrinking → dehydration, opening → presetting → warp beam rolling → dyeing → cold water washing → color fixing →washing→unwinding and rolling→softening and shaping→inspection→rolling and packing:

[0062] The refining process is as follows: refining in 8-section continuous refining machine, adding refining degreasing agent 8g / L and chelating dispersant 3g / L in the rolling tank, and controlling the water temperature in the refining tank of 8-section continuous refining machine as 65°C → 92°C ℃→75℃→75℃→60℃→60℃→40℃→40℃, the vehicle speed is 60m / min;

[0063] The pre-shrinking process uses an airflow dyeing machine for pre-shrinking, and heats it at 90°C for 30 minutes. The formula is:

[0064]

[0065] The temperature of the presetting process is 200°C, and the vehicle speed is 20-30m / min;

[0066] Adopt follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com