A kind of directional reaming screw drilling tool

A technology for reaming screws and drilling tools, which is applied to drill bits, drill pipes, drill pipes, etc., can solve the problems of affecting the build-up rate, failing to achieve the righting effect, and limiting the tripping and tripping of the directional drilling tools of the screw drilling tools. achieve good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

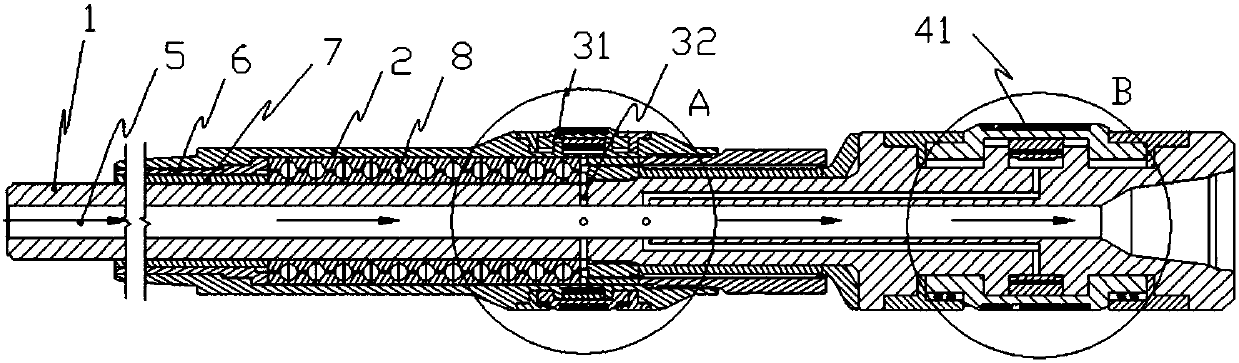

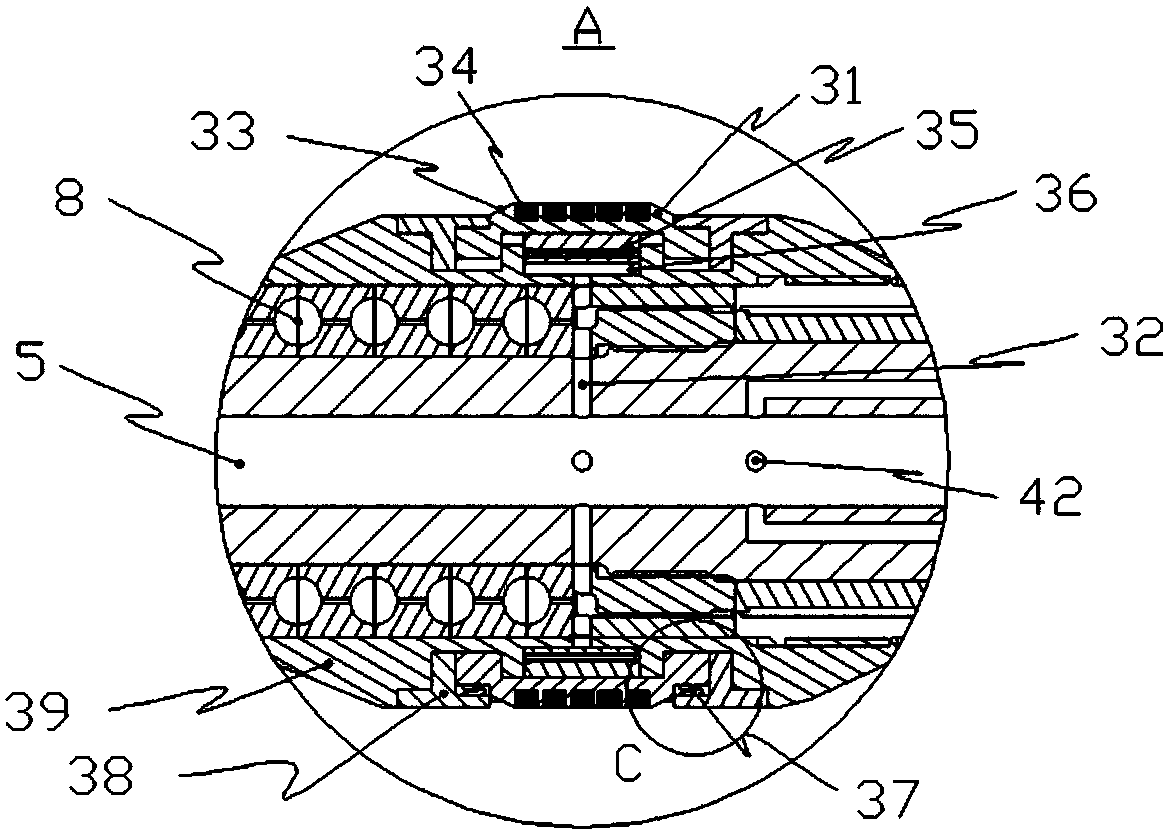

[0036] In the technical field of screw drilling tools, the head end or front end of the screw rod in front of the drilling direction, and correspondingly, the other end is the tail end or rear end. Therefore, in terms of azimuth, the head, tail and front and rear are clearly defined by the screw drilling tool. At the same time, the accessories on the screw drilling tool are also limited by the head and tail or front and rear under this condition.

[0037] In addition, the screw drilling tool is also a drilling pin based on rotation. Therefore, the corresponding radial, axial and circumferential directions are all defined by the drilling direction or the rotor 1 and the housing 2 .

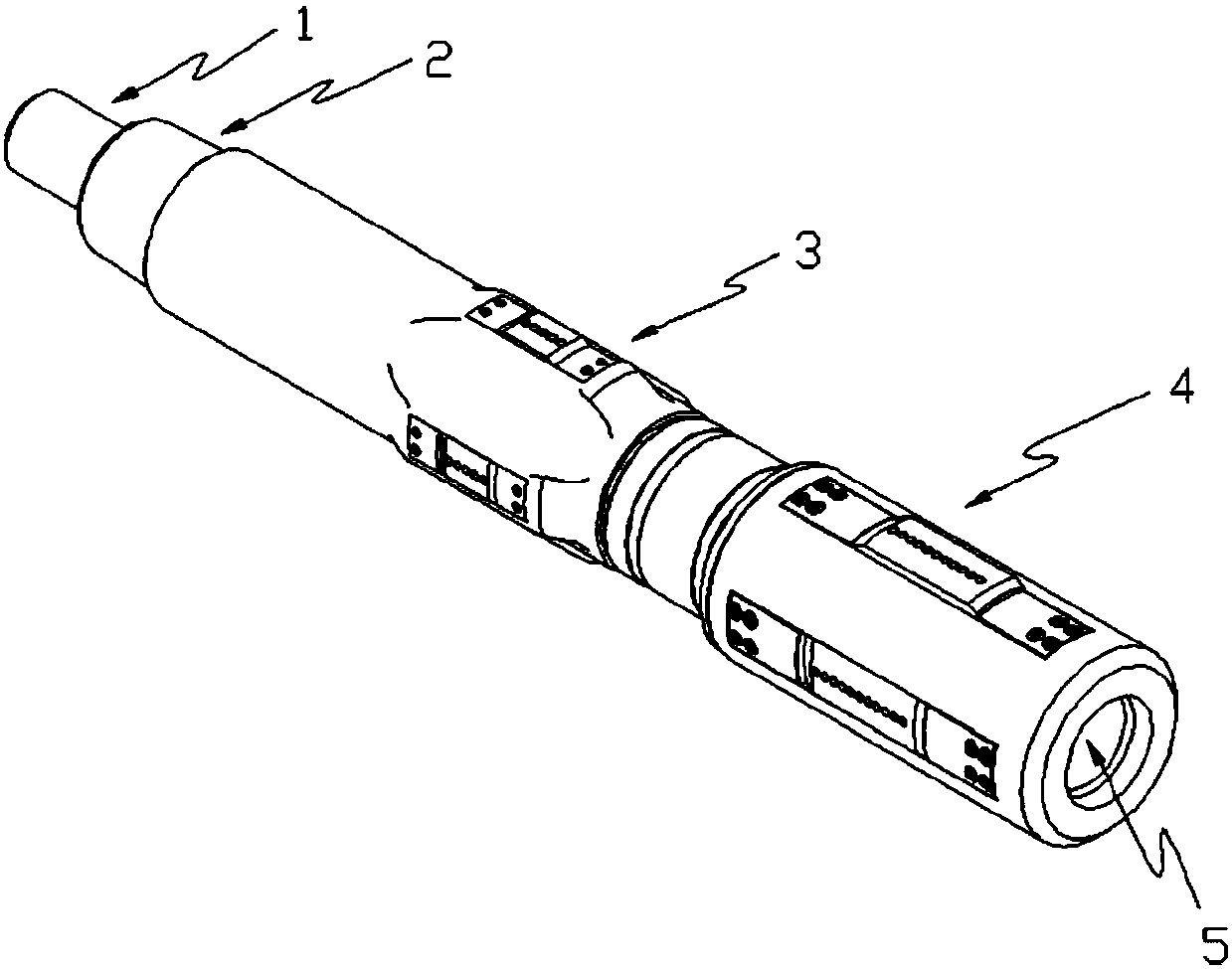

[0038] figure 1 The structure shown is a basic structure of a reaming screw for orientation. In the figure, the rotor 1 is used to connect the motor of the screw drilling tool to provide drilling power. The housing 2 can be integrated with the motor of the screw drilling tool. moving parts.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com