A method and system for position detection of planar robot based on capacitive touch screen

A technology of capacitive touch screen and detection method, applied in the direction of electric/magnetic position measurement, using electric device, electromagnetic measurement device, etc., can solve the problems of limited measurement range, complicated measurement process, expensive instrument cost, etc., and achieves convenient acquisition and simple method. Easy-to-run, easy-to-read effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

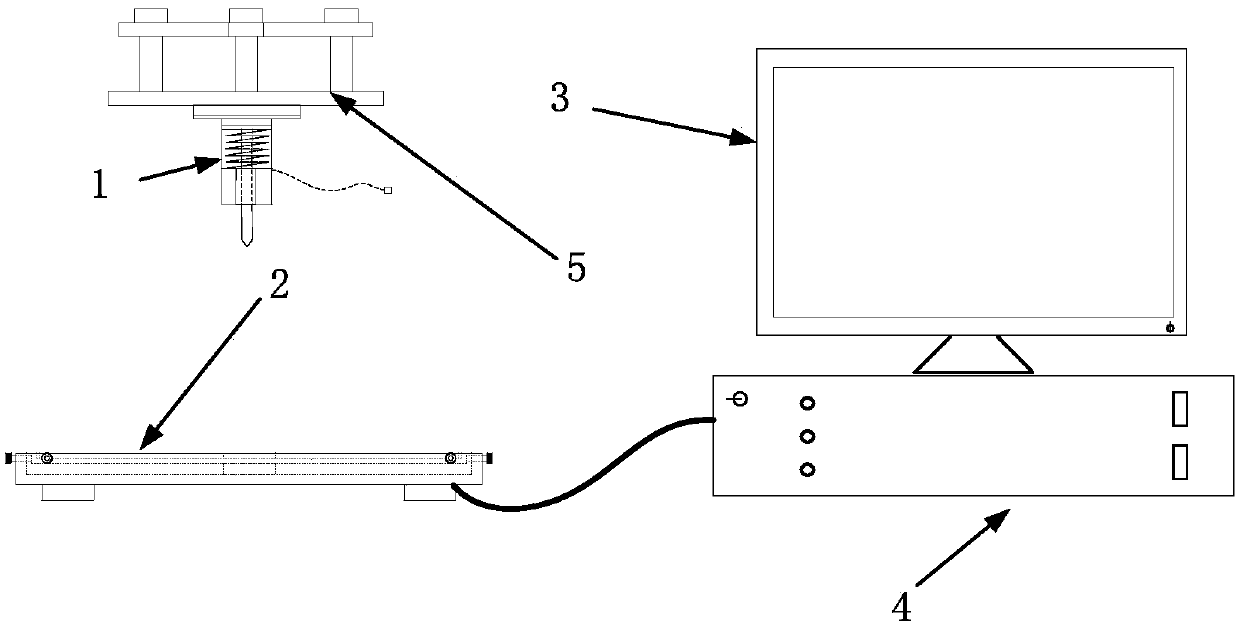

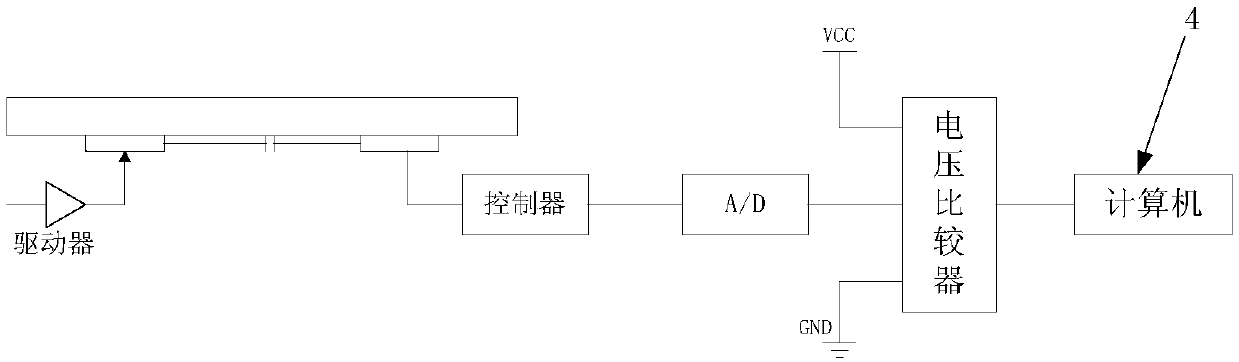

[0029] Example 1: figure 1 As shown, the planar robot position detection system based on the capacitive touch screen of the present invention includes a capacitive screen trigger device 1, a capacitive touch screen support device 2, a display screen 3, a computer 4, and an auxiliary fixing device 5. The capacitive screen trigger device 1 and the end of the detected robot The actuator is fixedly connected and is controlled by the computer 4 at the same time. The capacitive touch screen support device 2 and the display screen 3 are both connected to the computer 4. The auxiliary fixing device 5 is used when the actuator at the end of the detected robot is made of non-magnetic material. Fixed capacitor trigger device 1.

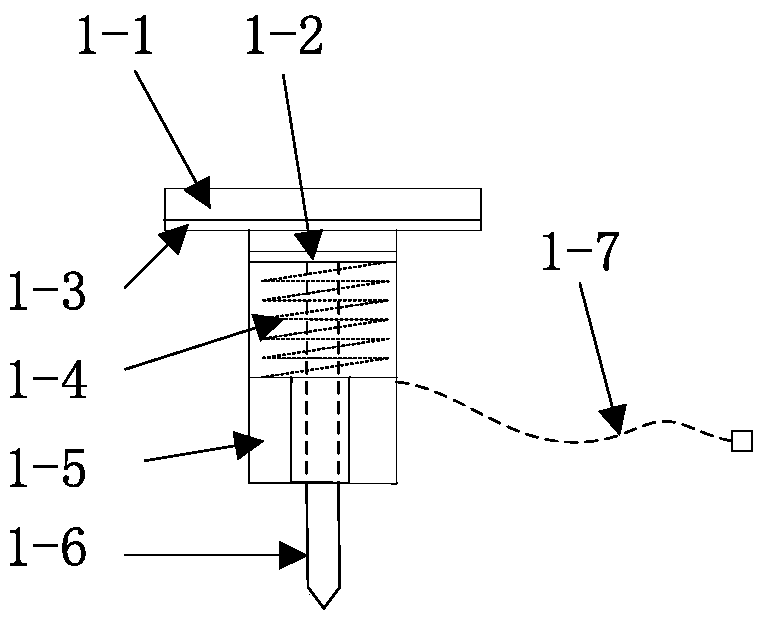

[0030] image 3 Shown: The capacitive screen trigger device 1 includes a fixed magnet 1-1, a spring control board 1-2, a magnetic isolation material 1-3, a return spring 1-4, an electromagnet 1-5 and a capacitive screen trigger 1-6, electromagnetic Iron connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com