Manufacture method of karst pile foundation anti-seismic test testing device

A technology of test device and production method, which can be used in measurement device, vibration test, machine/structural component test, etc., can solve the problem of lack of good test test device, and achieve low test cost, high test efficiency and novel design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0036] Such as Figure 1~12 Shown, a kind of manufacturing method of karst pile foundation seismic test test device comprises the following steps:

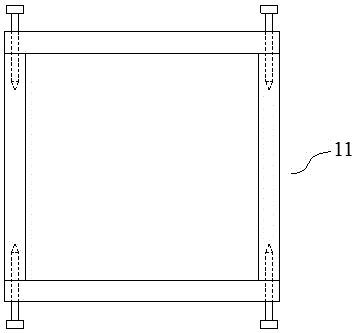

[0037] (1) Make the mold frame 11: use four plexiglass plates to form a detachable square mold frame 11;

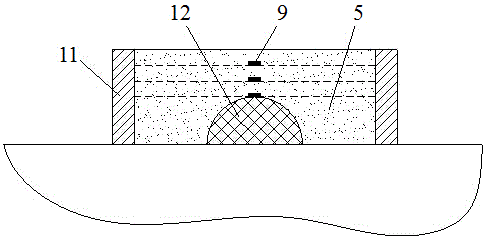

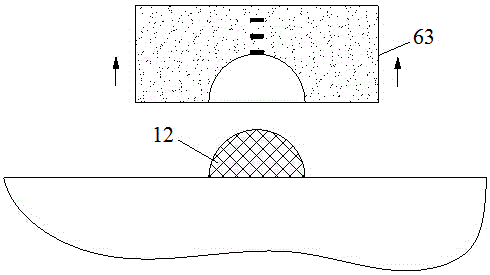

[0038] (2) Prefabricated cave model 6: first fix the mold frame 11 on the plane; then fix the hemispherical mold 12 with a predetermined diameter on the plane and in the middle of the mold frame 11; then weigh the model similar material 5 with a predetermined mass Pour it into the mold frame 11, and carry out layered compaction under the premise of ensuring the model density; then disassemble the mold frame 11, take out the hemispherical mold 12, and let it dry naturally to form a semi-karst cave model 63; ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com