Electrochemical testing experimental device for dynamic corrosion of metal

A technology of dynamic corrosion and testing experiments, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve the problems of inability to completely imitate ships, inability to measure metal materials, etc., and achieve fast and easier electrochemical corrosion measurement Calculation and control, effects of good corrosion mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

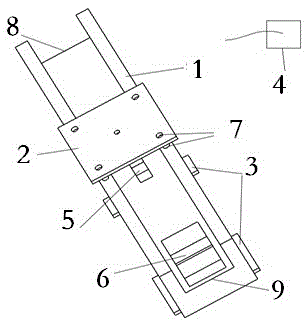

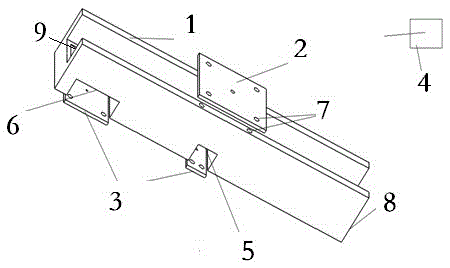

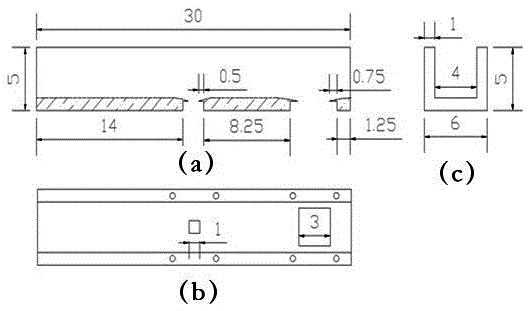

[0017] Such as figure 1 As shown, the electrochemical test experimental device for metal dynamic corrosion of the present invention mainly includes: flow tank 1, working electrode contact hole 5, counter electrode contact hole 6, M5 screw hole 7, solid pressure plate 3, electrode cover plate 2, liquid inlet 8. Liquid outlet 9, external interface 4, etc., combined with image 3 , the specific connection relationship in the experiment is as follows: the corrosive liquid flows into the liquid inlet 8 through the conduit in the circulating corrosive liquid system, and then the external interface 4, the metal sample and the counter electrode are fixed on the contact hole 5 of the working electrode and the counter electrode through the solid pressure plate 3 The contact hole 6 is tightened with screws through the screw hole 7 to make close contact with each other to form a seal. At the same time, the electrode cover plate 2 above the flow tank 1 is also screwed and fixed on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com