Corneal contact lens cleaning device and cleaning method adopting same

A technology for contact lenses and cleaning devices, applied in the directions of glasses/protective glasses, glasses/goggles, optics, etc., can solve the problem of difficulty in ensuring complete elimination of chlorine gas, failure to clean and disinfect contact lenses, and contamination of contact lenses. things cannot be removed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

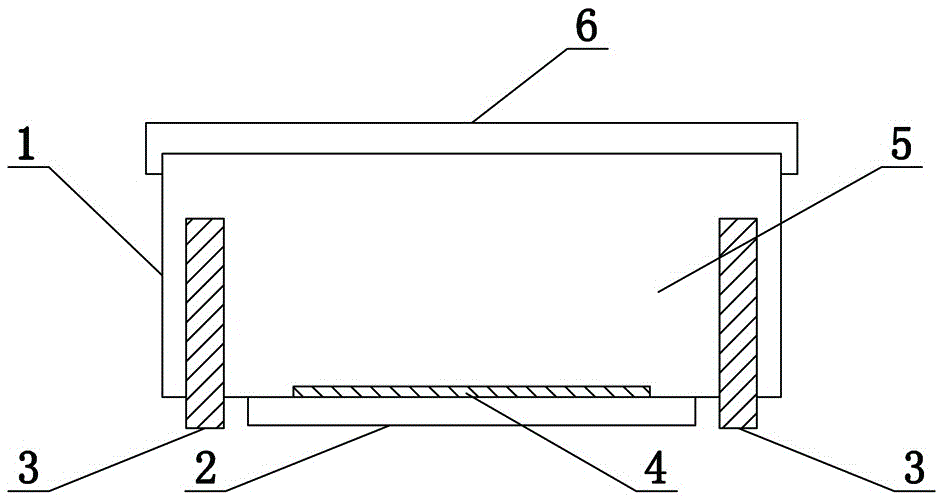

[0027] Such as figure 1 Shown, a kind of contact lens cleaning device, it comprises cleaning box body 1, and described cleaning box body 1 is used for accommodating cleaning liquid, and when cleaning, corneal contact lens is immersed in cleaning liquid, and in described cleaning box body 1 A transducer sheet 2 and two electrodes 3 are provided, and the transducer sheet 2 is connected with an ultrasonic generating circuit, and the ultrasonic generating circuit is used to provide an ultrasonic generating source, so that ultrasonic waves are generated through the transducer sheet 2 to realize corneal Ultrasonic cleaning of the contact lens; the electrodes 3 are connected with an electric field generating circuit, and the electric field generating circuit is used to provide an electric field generating source, so that an electric field is generated between the two electrodes 3 to realize electrophoretic cleaning of the corneal contact lens.

[0028] In this embodiment, two electro...

Embodiment 2

[0042] The main difference between this embodiment and embodiment 1 is: as figure 1As shown, the transducer sheet 2 is provided with a conductive layer 4, and the conductive layer 4 is electrically connected to the electric field generating circuit. At this time, the conductive layer 4 can be used as an electrode, and the specific setting method is: the electric field generating circuit One end of the circuit is connected to the conductive layer 4 , and the other end of the electric field generating circuit is respectively connected to the electrodes 3 , so that an electric field is generated between the conductive layer 4 and the electrodes 3 .

[0043] It should be noted that in other embodiments, since the conductive layer can be used as an electrode, a conductive sheet and an electrode can be arranged in the cleaning box as required, so that an electric field is generated between the two.

[0044] In this embodiment, the cleaning box 1 is provided with a transducer sheet 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com