Sorting label-coating visual detection electronic servo driving controls system

A technology of servo drive and visual inspection, applied in the field of servo drive control system, sorting and labeling visual inspection electronic servo drive control system, can solve the problems of inability to realize human-computer interaction, restrict production efficiency, and poor applicability, and achieve Reduce labor costs, achieve product labeling classification, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

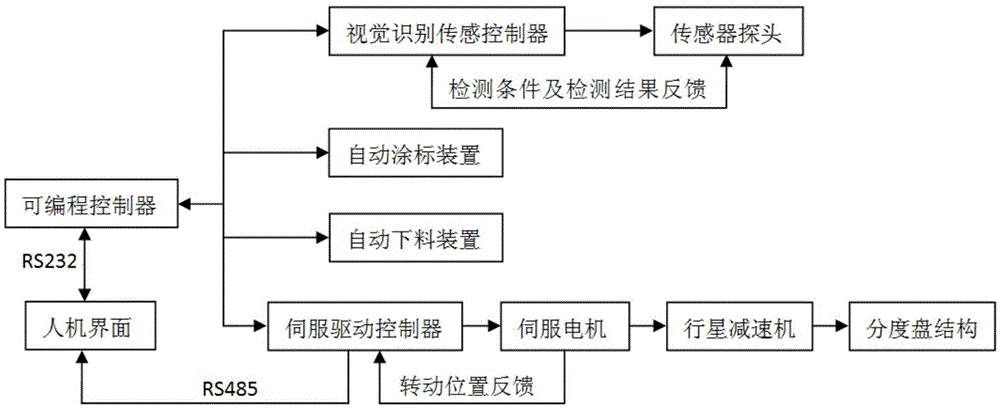

[0020] see figure 1 , the present invention discloses an electronic servo drive control system for visual detection of sorting and labeling, which is mainly composed of an electronic servo drive controller, a servo motor, a high-precision visual recognition sensor, an automatic labeling device, a high-precision positioning device, and a programmable control system. device, man-machine interface, and solenoid valve. The programmable controller and the servo drive controller are connected to the man-machine interface through the communication interface; the drive output end of the servo drive controller is connected to the servo motor; the signal input end of the servo drive controller is connected to the output end of the programmable controller; the visual recognition transmission The signal input terminal of the sensor controller is connected to the output terminal of the programmable controller; the output terminal of the visual recognition sensor controller is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com