Method and device for recovering waste battery electrolyte organic solvent

An organic solvent and waste battery technology, which is applied in the field of waste battery recycling and can solve problems such as secondary pollution, organic solvent leakage, and unfriendly environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

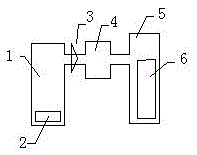

[0007] The cylindrical lithium-ion single battery passes through the drilling machine. The drill bit of the drilling machine drills a hole in the bottom wall of the cylindrical battery. Chamber exhaust valve, open the vacuum pump, open the cooling device of the liquefaction chamber. The organic solvent inside the battery is quickly vaporized under the condition of reduced pressure and heating, and the vaporized organic solvent escapes to the vaporization chamber through the drilling holes on the outer wall of the battery. , the high-temperature and high-pressure solvent gas is liquefied after being cooled by the cooling device in the liquefaction chamber.

Embodiment 2

[0009] The soft-packed lithium-ion single battery passes through the puncture machine, and the knife head of the puncture machine punctures a hole on the outer wall of the soft-packed battery. The battery after the puncture hole is put into the vaporization chamber, the vaporization chamber is closed, the vaporization chamber heating device is turned on, and the vaporization chamber exhaust valve is opened. , turn on the vacuum pump, and turn on the cooling device of the liquefaction chamber. The organic solvent inside the battery is quickly vaporized under the condition of reduced pressure and heating, and the vaporized organic solvent escapes to the vaporization chamber through the drilling holes on the outer wall of the battery. , the high-temperature and high-pressure solvent gas is liquefied after being cooled by the cooling device in the liquefaction chamber.

Embodiment 3

[0011] The square lithium-ion single battery passes through the drilling machine, and the drill bit of the drilling machine drills a hole on the outer wall of the square battery. The drilled battery is placed in the vaporization chamber, the vaporization chamber is closed, the vaporization chamber heating device is turned on, and the vaporization chamber is opened to pump air. valve, turn on the vacuum pump, and turn on the cooling device of the liquefaction chamber. The organic solvent inside the battery is rapidly vaporized under the condition of reduced pressure and heating, and the vaporized organic solvent escapes to the vaporization chamber through the drilling holes on the outer wall of the battery. , the high-temperature and high-pressure solvent gas is liquefied after being cooled by the cooling device in the liquefaction chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com