A method and device for reducing arc plasma generator electrode ablation

A technology of arc plasma and generator, which is applied in the direction of plasma and electrical components, and can solve the problems of complex structure and high maintenance cost of thermal plasma generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

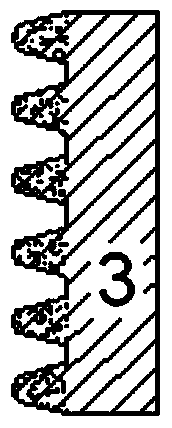

[0029] The basic idea of the present invention is to carry out mechanical knurling, wire drawing, sandblasting, shot blasting and other treatments on the electrode surface of the arc plasma generator to change the electrode surface morphology, stress state, microstructure and crystal phase structure, thereby changing the electrode surface. The energy condition of the arc will affect the attachment reaction energy of the arc attached to the electrode surface or disperse and micronize the attachment points, thereby reducing electrode ablation and improving the operation stability and life of the arc plasma generator.

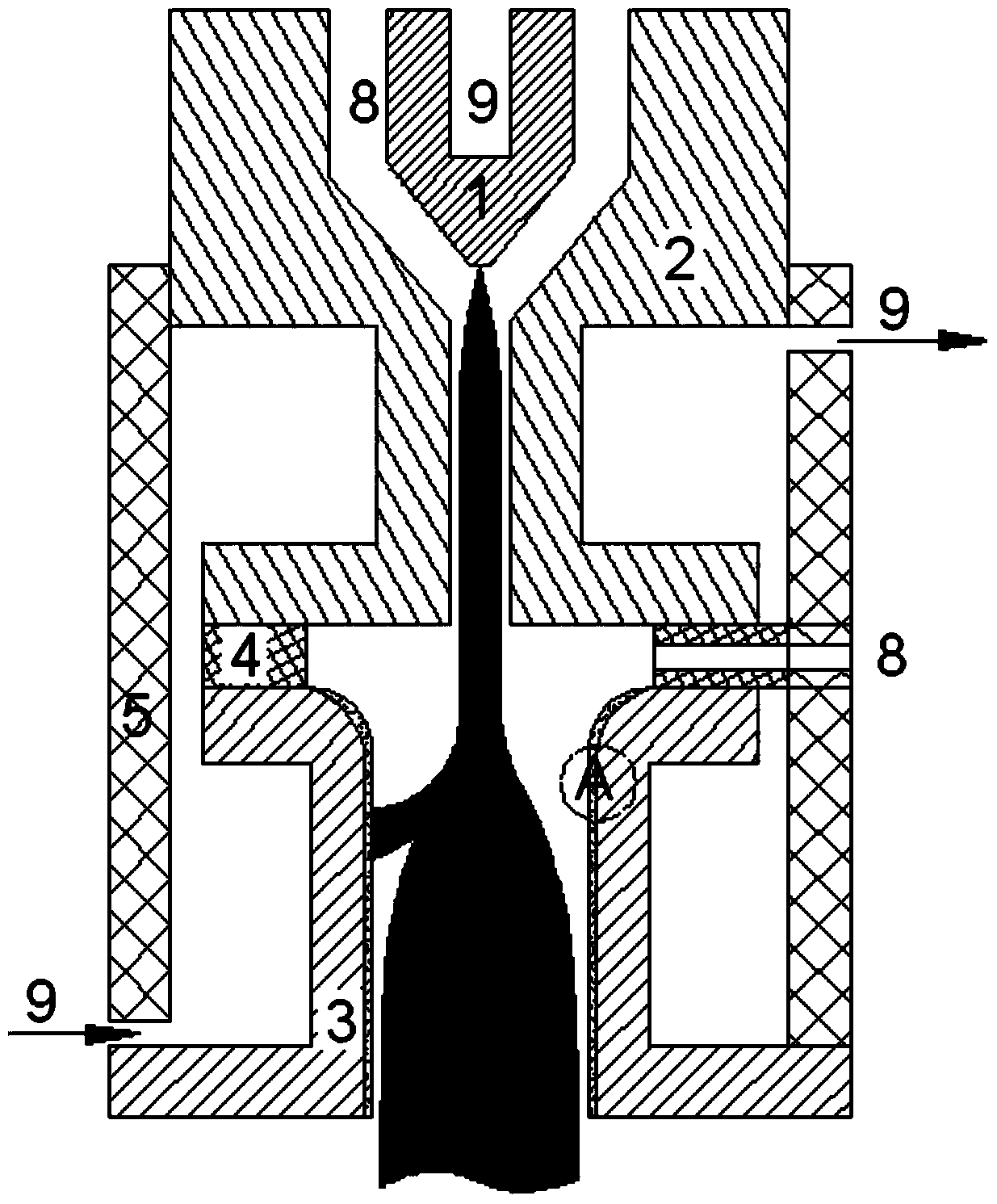

[0030] figure 1 Provided is an arc plasma generator for reducing electrode ablation, a cathode 1 , an intermediate section 2 , an anode 3 , an insulating member 4 and an outer sleeve 5 . The middle section 2 is arranged downstream of the arc transmission direction of the cathode 1; the anode 3 is surface-treated to make the anode 3 have a specific surface struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com