Fabrication method of metal housing

A manufacturing method and technology of metal casing, applied in the field of metal processing, can solve problems such as increased process cost, poor product consistency, poor product yield, etc., and achieve the effects of avoiding corrosion effects, good consistency, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

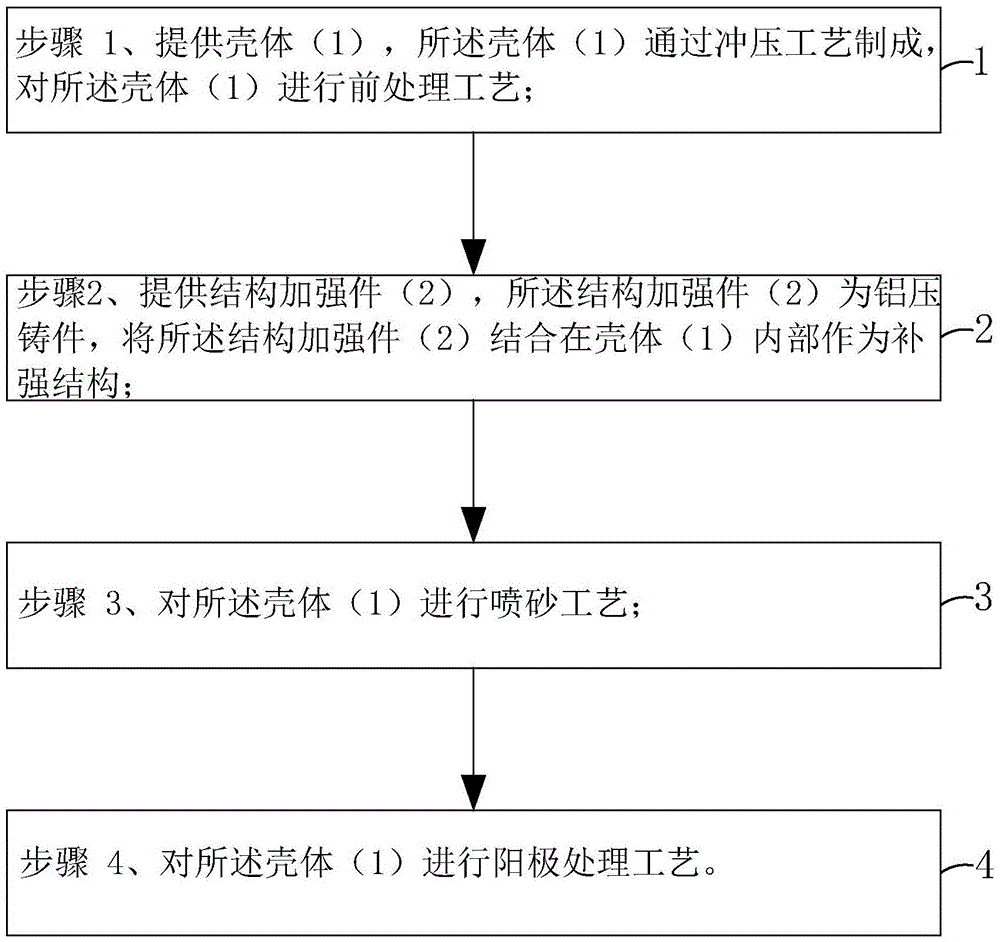

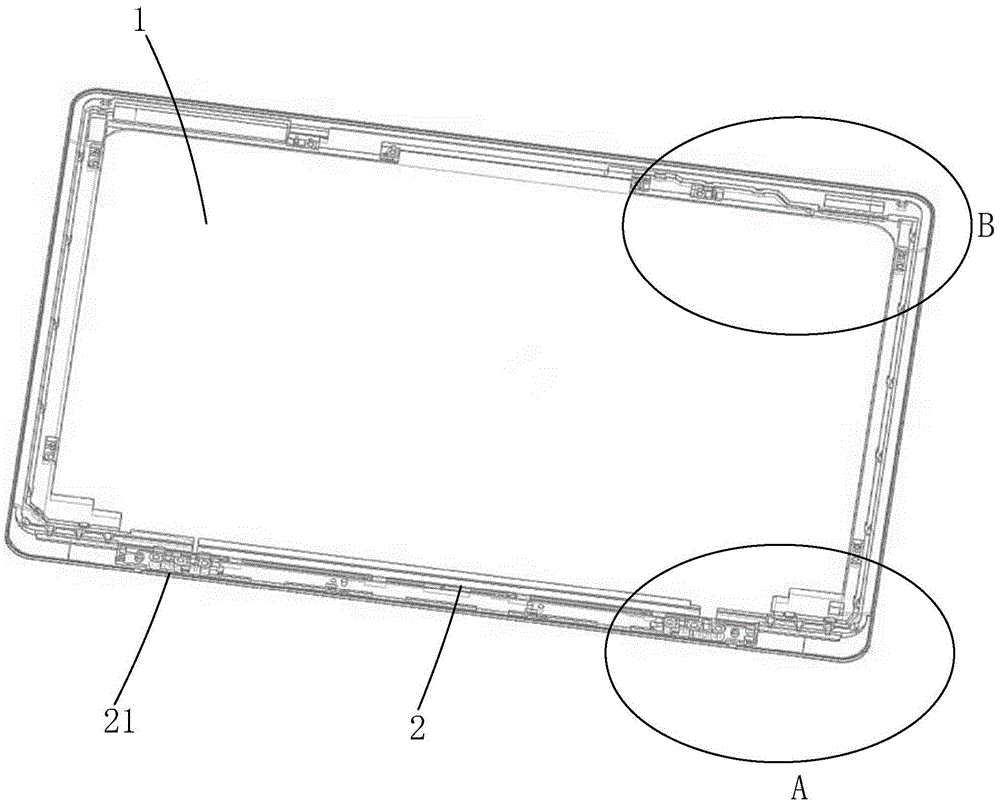

[0030] see figure 1 , and combined with Figure 2 to Figure 5 , the invention provides a method for making a metal shell, comprising the steps of:

[0031] Step 1, providing a housing 1, the housing 1 is made by a stamping process, and the housing 1 is subjected to a pre-treatment process.

[0032] Specifically, the pre-treatment process includes rough cutting, bending, CNC machining, cleaning oil, and drying. The casing 1 is processed into a predetermined shape by bending and numerically controlled machine tools, and the oil pollution on the surface of the casing 1 and other impurities adsorbed on the surface are removed by a degreasing process.

[0033] Specifically, the material of the housing 1 can be selected from aluminum alloy, prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com