Method of producing sterile aquaculture water, and method using same of fish aquaculture using flowing sterile water

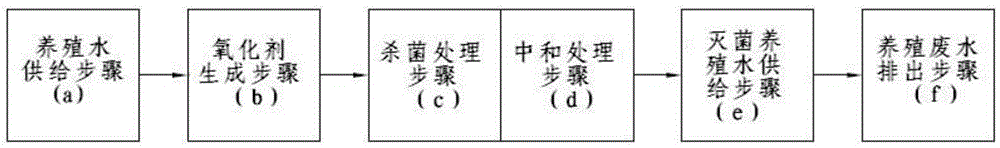

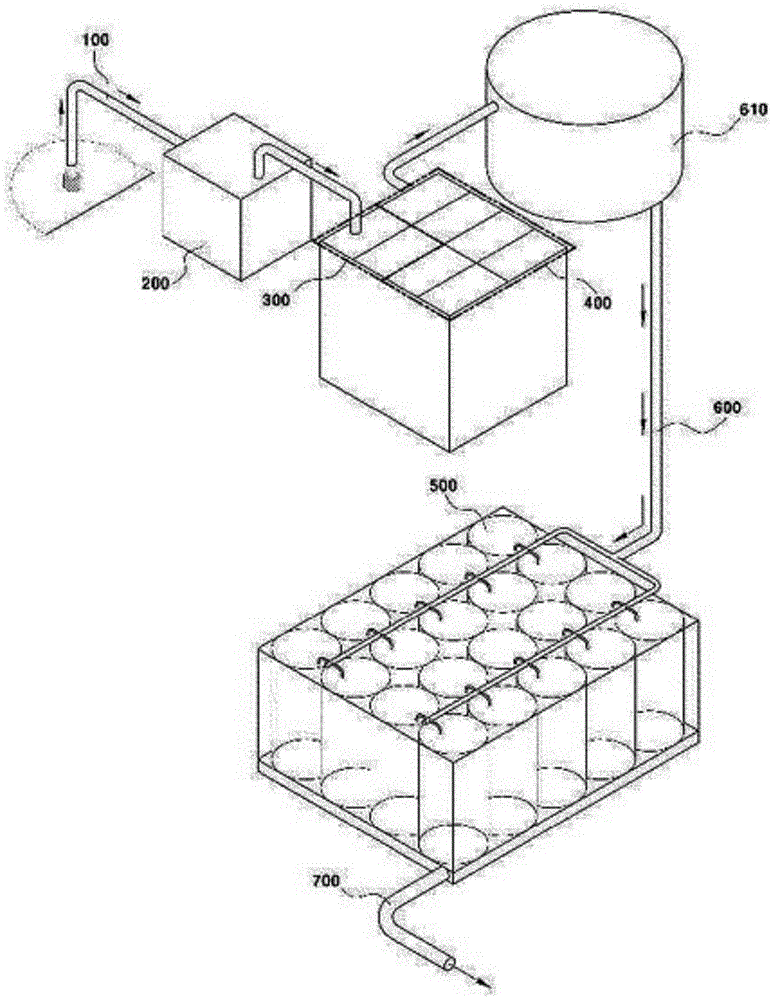

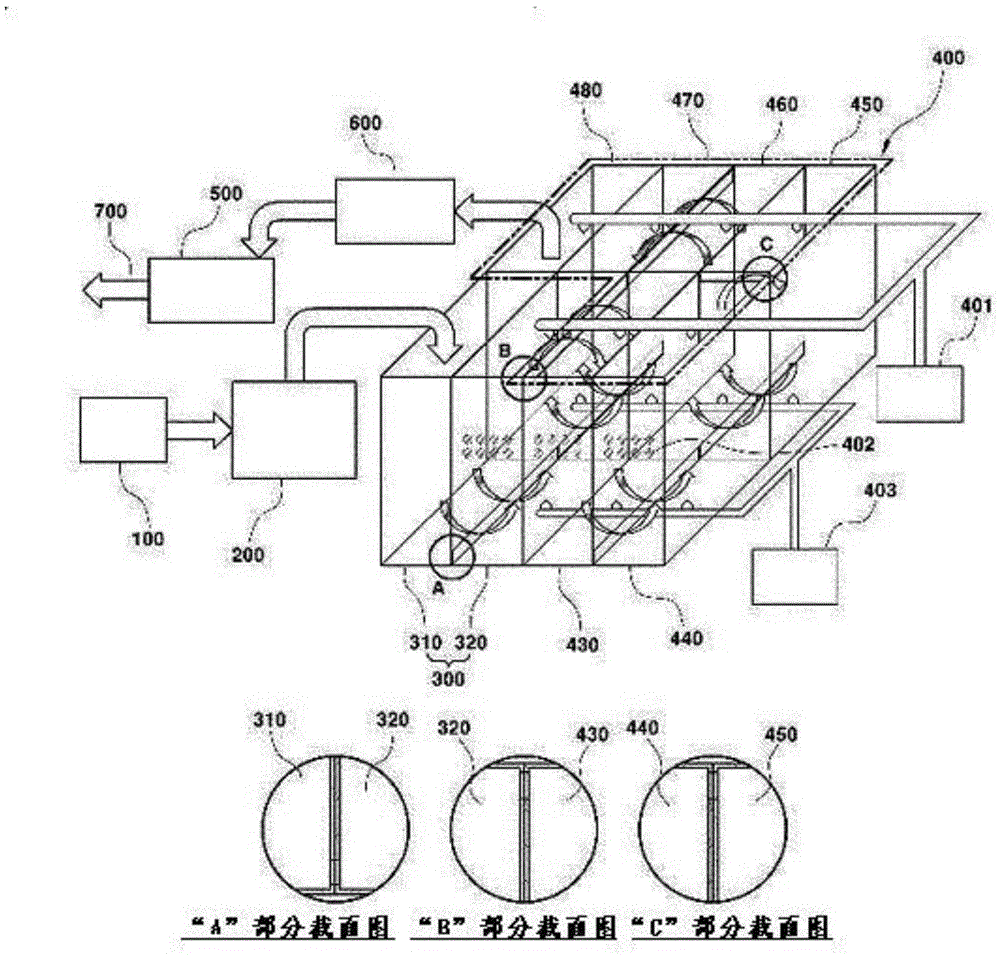

A technology for fish breeding and aquaculture water, which is applied in the field of preparation of sterilized aquaculture water, can solve problems such as being unable to be put into practice normally, and achieve the effect of continuous sterilization treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0208] Seawater and groundwater on the surface of Seogwipo City, Jeju Island were mixed in a ratio of 50:50, and were injected at the usual water injection port flow rate (20-30cm / second) in the fish farm, and as shown in the following Table 3 As shown, the voltage and current density were changed and electrolysis was performed, and then the concentration of bromate produced was analyzed.

[0209] The concentration of organic substances contained in the seawater, the concentration of sodium bromide (NaBr), and the salinity are different for each location in this region classified according to the region. Therefore, it is determined that the surface is the most standard region and location , so the good surface is selected.

[0210] table 3

[0211]

preparation Embodiment 2

[0213] The groundwater on the surface that hardly contains organic matter was flowed and transported at a flow rate of 20-30 cm / sec, and electrolyzed with the conditions in Table 4 below, and then the concentration of bromate was measured. At this time, the content of sodium bromide (NaBr) in seawater was 63.3 mg / L as Br.

[0214] Table 4

[0215] Voltage (Volts)

preparation Embodiment 3

[0217] Only the seawater on the surface was used, and the flow rate was set at 20-30 cm / sec, and electrolysis was performed under the conditions of Table 5 below, thereby measuring the content of bromate. The results are shown in Table 5 below. At this time, the content of sodium bromide (NaBr) in seawater was 63.7 mg / L as Br.

[0218] table 5

[0219] Voltage (Volts)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com