Viscous oil emulsion preparation method and viscous oil conveying method

An oil-in-water emulsion, emulsion technology, applied in mixing methods, chemical instruments and methods, emulsification and other directions, can solve problems such as easy demulsification, emulsion instability, pipeline blockage, etc., to extend stability and meet long-distance The effect of conveying and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] According to the method for preparing a thick oil emulsion of the present invention, the thick oil can be mixed with an emulsifier, a stabilizer and water by a conventional method, and the thick oil can be formed into droplets and dispersed in water, for example, in a mixer with a shearing function. Or in a static mixer, thick oil is mixed with emulsifiers, stabilizers and water to form an oil-in-water emulsion.

[0025] The method for preparing a thick oil emulsion according to the present invention includes step (2): cooling the oil-in-water emulsion to a second temperature, and the viscosity of the thick oil at the second temperature is not less than 2000mPa·s .

[0026] From the perspective of further improving the stability of the oil-in-water emulsion, the viscosity of the heavy oil at the second temperature is preferably in the range of 20,000-2,000,000 mPa·s. When the heavy oil is heavy oil with relatively high wax content, the viscosity of the heavy oil at the...

Embodiment 1

[0038] Yaoyingtai heavy oil-1 is used in this embodiment, and its properties are listed in Table 1.

[0039] Table 1

[0040] Asphaltenes / wt%

0.4

Colloid / weight%

17.9

Wax content / wt%

20.7

[0041] Under the first temperature, Yaoyingtai thick oil-1 and emulsifier (nonylphenol polyoxyethylene ether (polymerization degree 15), referred to as NP-15), stabilizer (polyacrylamide, number average molecular weight is 5,000,000 , referred to as PAM) and water to form an oil-in-water emulsion. The formed oil-in-water emulsion is cooled to the second temperature, and the stable existence time of the oil-in-water emulsion at the second temperature is measured.

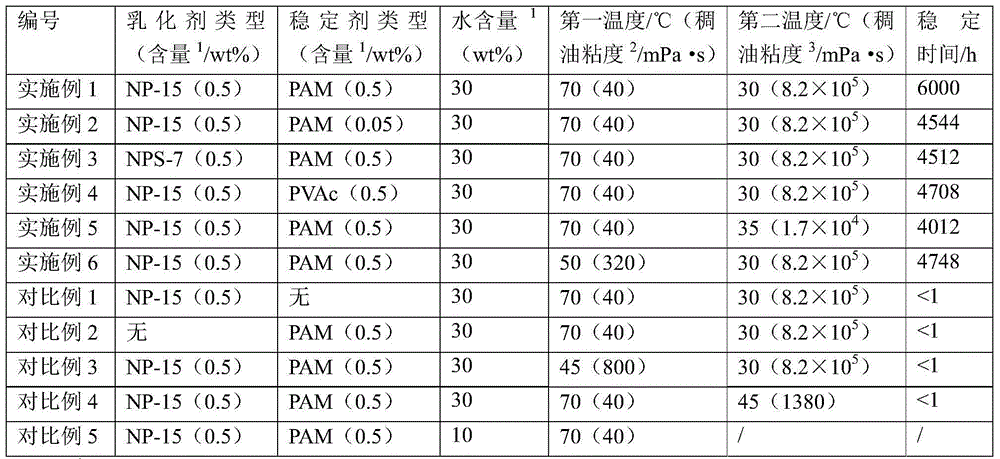

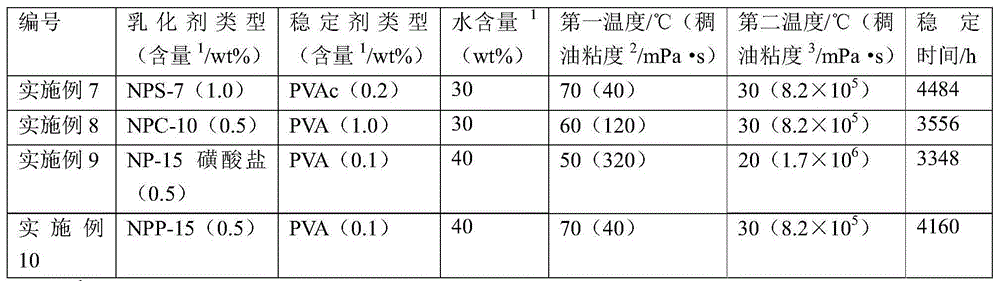

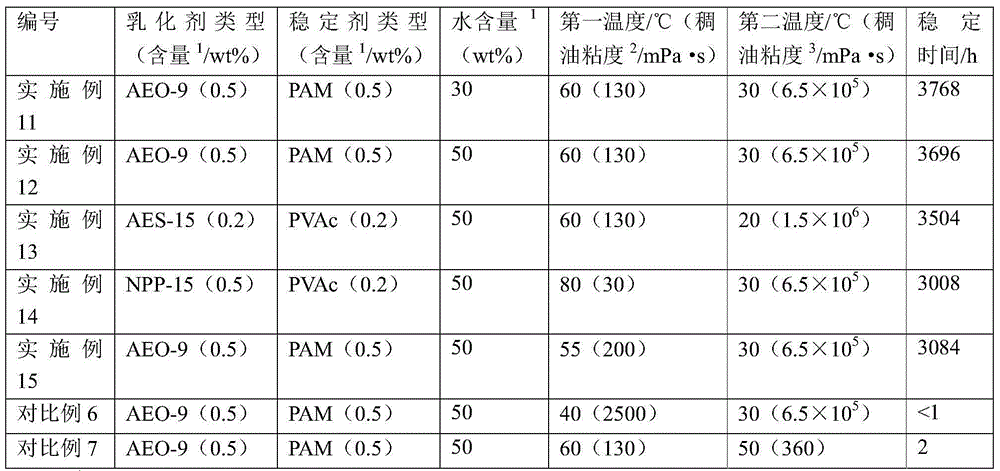

[0042] The experimental conditions and results are listed in Table 2.

Embodiment 2

[0044] The oil-in-water emulsion was prepared by the same method as in Example 1, except that the ratio between the emulsifier and the stabilizer was changed. The experimental conditions and results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com