Continuous copper strip stamping worktable

A workbench and copper strip technology, applied in the field of punching machines, can solve the problems of being unsuitable for large-scale production, heavy workload of workers, and low degree of automation, achieving huge economic and social benefits, simple structure, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

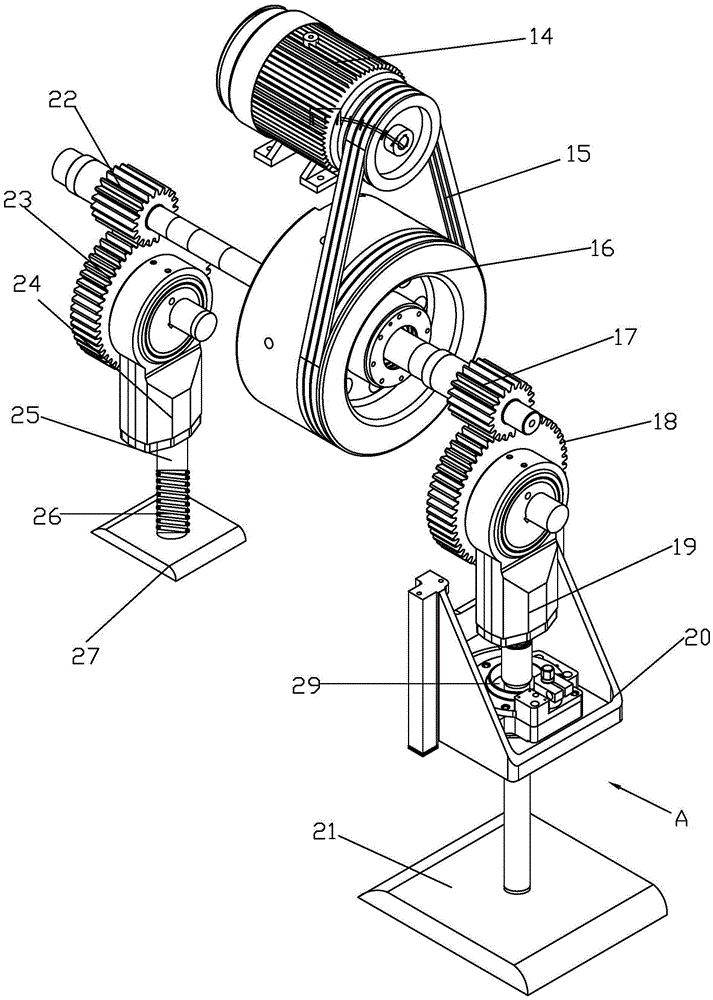

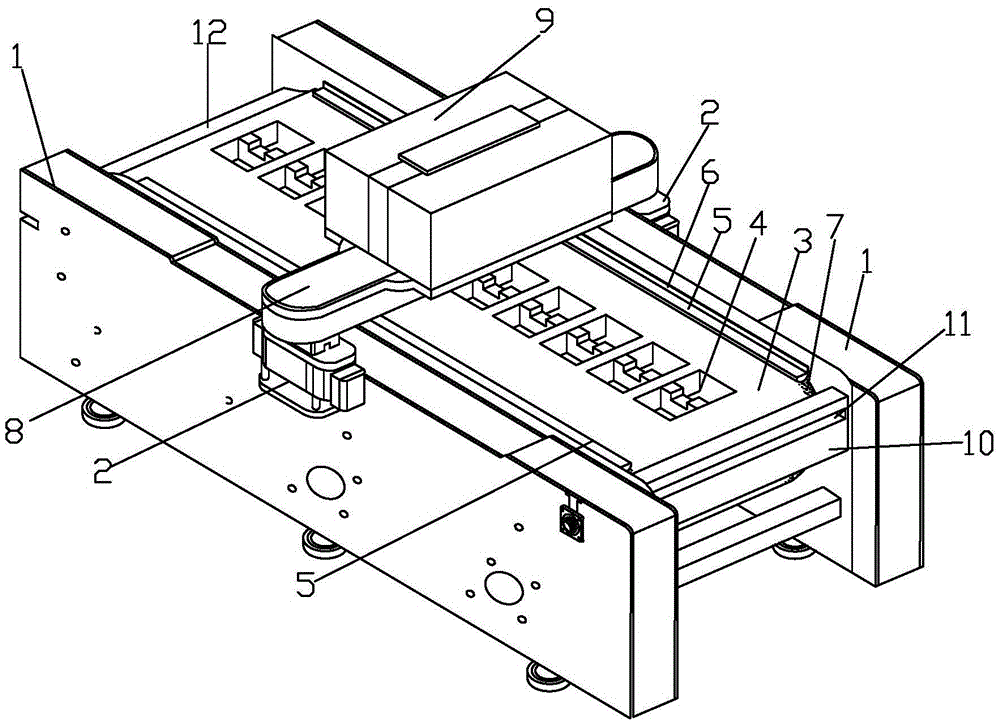

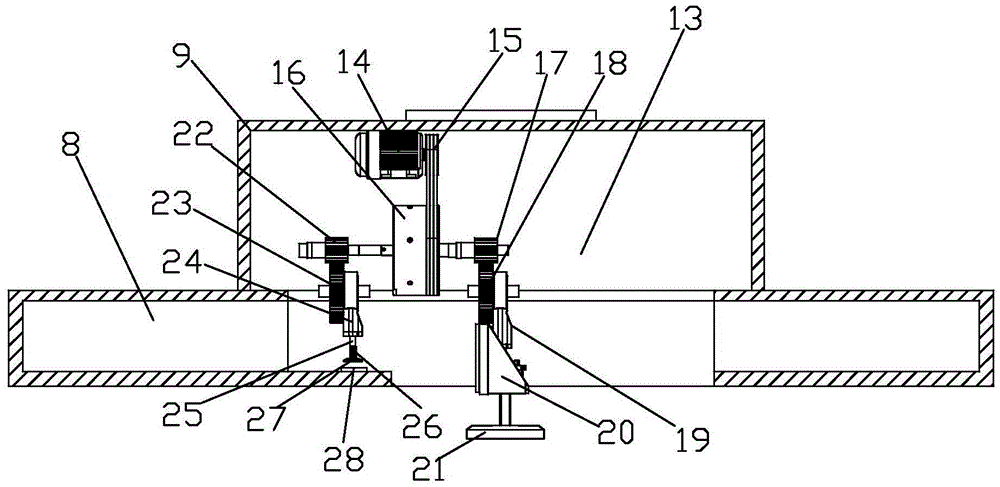

[0028] Such as Figure 1 to Figure 6 As shown, a continuous copper strip stamping workbench includes a frame 1, an upper mold 21, a lower mold 4 and a lifting mechanism. The frame 1 is composed of the left frame 1 and the right frame 1. The frame 1 is 10m long and 0.95m wide. The frame 1 is made of steel and has a firm structure. A guide belt 3 is connected between the left frame 1 and the right rack 1, and the guide belt 3 is laid with guide belt adhesive 7 on the left and right sides. The guide belt adhesive 7 is viscous and can stick to the copper belt so that it The guide belt 3 moves at a constant speed, and continuous production is realized on this basis. The guide belt glue 7 is easy to obtain materials and low in cost; the guide belt 3 is fixed with a lower mold 4, and the lower molds 4 are uniformly arranged at an interval of 0.25m; each lower mold 4 The bottom of each is equipped with a hydraulic cylinder 30, and the hydraulic cylinder 30 corresponds to the lower mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com