Preparation method of food standard substance lauric acid

A technology of lauric acid and standard products, which is applied in the field of preparation of food standard lauric acid, which can solve the problems of accuracy impact, environmental pollution, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

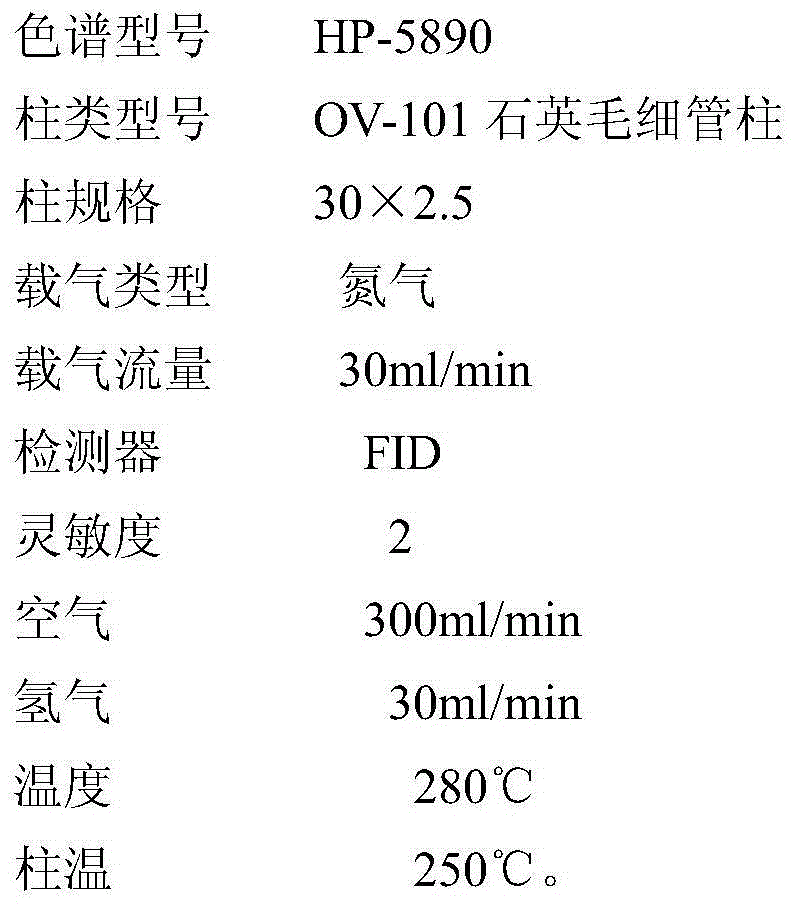

Image

Examples

Embodiment 1

[0018] A preparation method of food standard product lauric acid, the steps are as follows:

[0019] Take 1Kg of lauric acid with a content of 98%, put it into a melter, install a stirring device, put it in a 60°C water bath, heat it to dissolve it completely, take out the melter, start stirring, and let it cool slowly. When part of the precipitation is observed, the stirring is stopped immediately, and the upper liquid is collected in another melting tube for secondary melting. The remaining solid was removed from the melt and placed in a large beaker for later use. The two molten solids were combined. Wash twice with cold petroleum ether and dry in a vacuum dryer at 30-40°C for 2-3 hours to obtain 750 g of lauric acid with a yield of 75% and a content of 99.0%.

Embodiment 2

[0021] A preparation method of food standard product lauric acid, the steps are as follows:

[0022] Weigh 1.5Kg of industrial lauric acid with a content of 98%, add 2 liters of chromatographic grade hexane, heat to dissolve, boil for 2-3min, filter, put the filtrate in a 5L distillation bottle, recover about 500ml of hexane by distillation, pour it into a beaker, and carry out Cooling, at 20-30°C, crystals are precipitated, washed with cold hexane for 2-3 times, and dried in a vacuum dryer at 30-40°C for 2-3 hours, with a yield of 80% and a content of 99.5%.

[0023] If a product with a higher content is required, the above-mentioned crystallization is then subjected to the above-mentioned secondary crystallization, the content is 99.9%, and the yield is 60%.

Embodiment 3

[0025] The lauric acid of Example 1 grade is crystallized in the first step of Example 2 to obtain 99.9% lauric acid with a yield of 60%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap