Method for depositing functionally-graded nano-multilayer coating on surface of steel workpiece and product comprising functionally-graded nano-multilayer coating

A functionally gradient and nano-multilayer technology, applied in coating, metal material coating process, ion implantation plating, etc. Increased control difficulty and other issues, to overcome the effect of insufficient density of the film structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

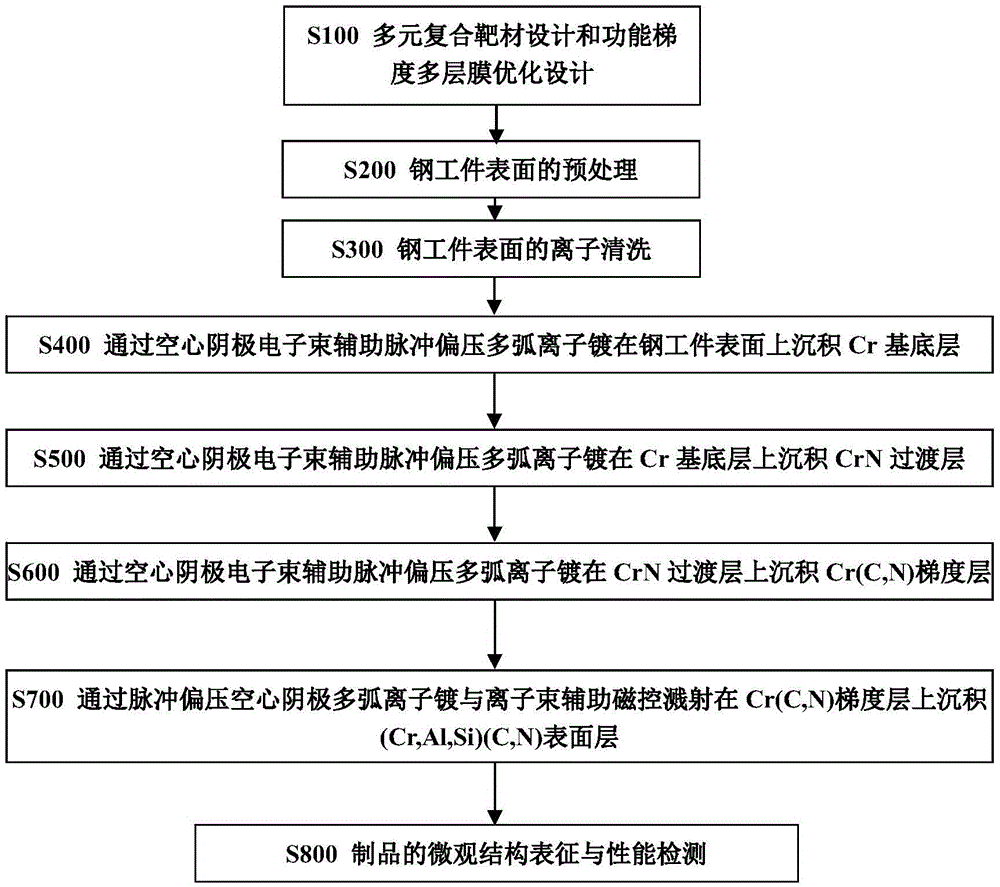

Method used

Image

Examples

Embodiment 1

[0144] 1) Pretreatment of stainless steel workpieces: At room temperature, place the polished stainless steel watch exterior parts in an ultrasonic cleaner filled with environmentally friendly water-based metal cleaning fluid for surface cleaning and degreasing; then put the cleaned workpieces into ethanol solution for dehydration treatment After drying.

[0145] 2) Ion cleaning of the surface of the workpiece: (1) Place the polished stainless steel watch exterior parts in the reactor and keep the vacuum in the reactor at 9.0×10 -3 Pa; (2) Start the Ta-HCD electron gun and the heating device in the furnace and control the current to 80A after the Ta-HCD electron gun is arcing. The plasma arc of the Ta-HCD source directly irradiates the surface of the workpiece until the temperature in the vacuum chamber reaches 120°C; (3) Keep the vacuum in the reactor at 9.0×10 -3 Pa, adjust the Ta-HCD electron gun current to 100A and apply a pulse negative bias to the workpiece to -100V; (4) Sta...

Embodiment 2

[0157] 1) Pretreatment of stainless steel workpieces: At room temperature, place the polished stainless steel watch exterior parts in an ultrasonic cleaner filled with environmentally friendly water-based metal cleaning fluid for surface cleaning and degreasing; then put the cleaned workpieces into ethanol solution for dehydration treatment After drying.

[0158] 2) Ion cleaning of the surface of the workpiece: (1) Place the polished stainless steel watch exterior parts in the reactor and keep the vacuum in the reactor at 5.0×10 -3 Pa; (2) Start the Ta-HCD electron gun and the heating device in the furnace and control the current to 80A after the Ta-HCD electron gun is arcing. The plasma arc of the Ta-HCD source directly irradiates the surface of the workpiece until the temperature in the vacuum chamber reaches 120°C; (3) Keep the vacuum in the reactor at 5.0×10 -3 Pa, adjust the Ta-HCD electron gun current to 100A and apply a pulse negative bias to the workpiece to -100V; (4) Sta...

Embodiment 3

[0171] 1) Pretreatment of stainless steel workpieces: At room temperature, place the polished stainless steel watch exterior parts in an ultrasonic cleaner filled with environmentally friendly water-based metal cleaning fluid for surface cleaning and degreasing; then put the cleaned workpieces into ethanol solution for dehydration treatment After drying.

[0172] 2) Ion cleaning of the surface of the workpiece: (1) Place the polished stainless steel watch exterior parts in the reactor and keep the vacuum in the reactor at 7.0×10 -3 Pa; (2) Start the Ta-HCD electron gun and the heating device in the furnace and control the current to 80A after the Ta-HCD electron gun is arcing. The plasma arc of the Ta-HCD source directly irradiates the surface of the workpiece until the temperature in the vacuum chamber reaches 120°C; (3) Keep the vacuum in the reactor at 7.0×10 -3 Pa, adjust the Ta-HCD electron gun current to 100A, and apply a pulse negative bias to the workpiece to -100V; (4) St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com