Polypropylene acoustic wool and preparation technology thereof

A preparation process, polypropylene technology, applied in the field of non-woven fabrics, can solve the problems of difficult blending, poor product thermal stability, poor sound absorption effect, etc., to achieve good sound absorption effect, controllable production process, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

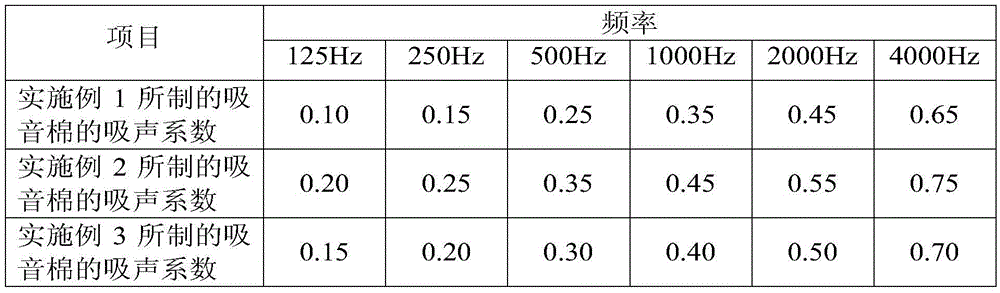

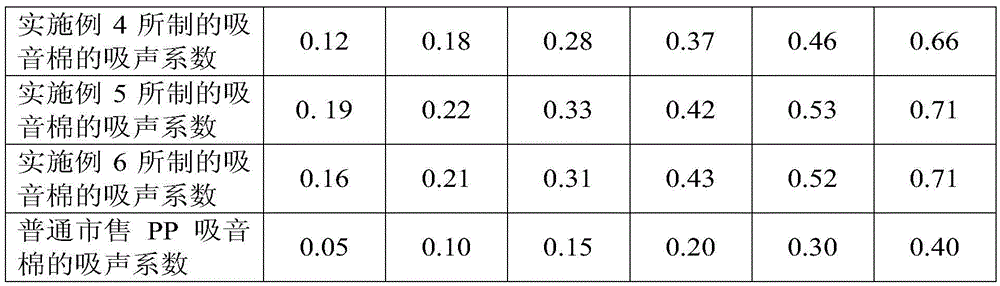

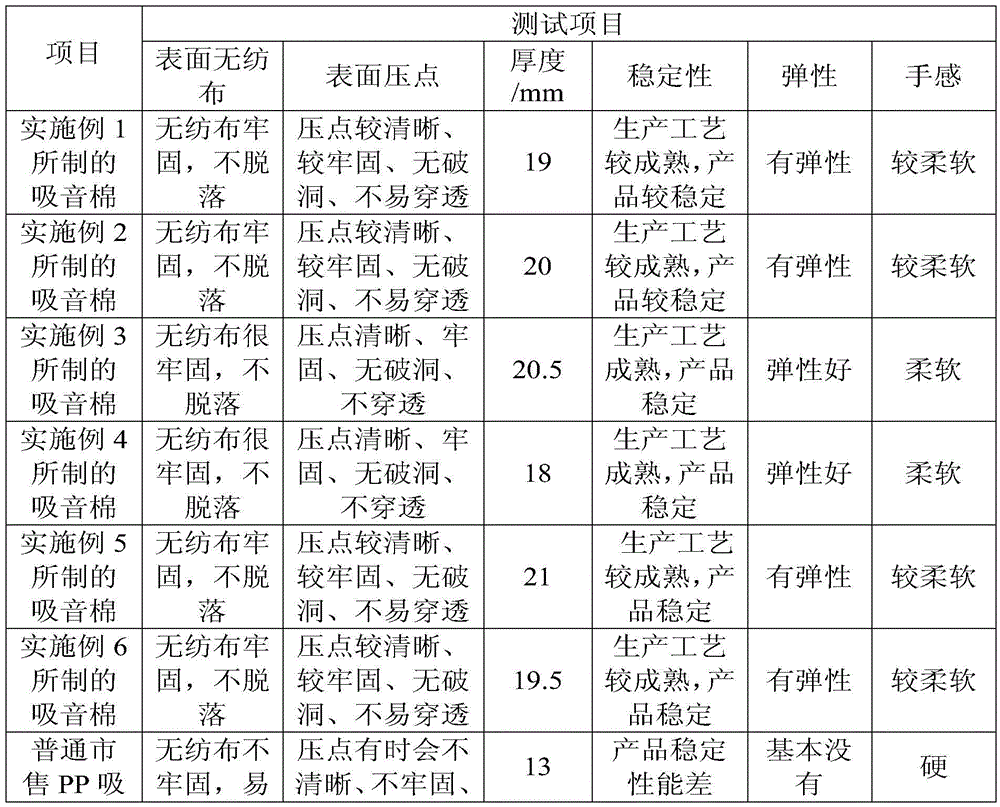

Embodiment 1

[0032] A polypropylene sound-absorbing cotton

[0033] Raw materials include: non-woven fabric, the mass per unit area is 200g / m 2 , the bulk density is 0.25g / m 3 ; And polypropylene blend fiber, composed of 5wt% syndiotactic polypropylene and 95wt% isotactic polypropylene. The MFR of the syndiotactic polypropylene is: 450g / 10min, and the MWD is: 1.8. Among them, the MFR of isotactic polypropylene is: 200g / 10min, and the MWD is: 2.

Embodiment 2

[0035] A polypropylene sound-absorbing cotton

[0036] Raw materials include: non-woven fabric, the mass per unit area is 400g / m 2 , the bulk density is 0.35g / m 3 ; and polypropylene blend fibers, composed of 12wt% syndiotactic polypropylene and 88wt% isotactic polypropylene. The MFR of the syndiotactic polypropylene is: 750g / 10min, and the MWD is: 2.9. Among them, the MFR of isotactic polypropylene is: 250g / 10min, and the MWD is: 3.5.

Embodiment 3

[0038] A polypropylene sound-absorbing cotton

[0039] Raw materials include: non-woven fabric with a mass per unit area of 300g / m 2 , bulk density is 0.30g / m 3and a polypropylene blend fiber consisting of 8.5wt% syndiotactic polypropylene and 91.5wt% isotactic polypropylene. The MFR of the syndiotactic polypropylene is: 600g / 10min, and the MWD is: 2.3. Among them, the MFR of isotactic polypropylene is: 225g / 10min, and the MWD is: 2.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com