Disc mill control method

A control method and disc mill technology, applied in the field of disc mill control, can solve difficult disc mill, control and other problems, and achieve the effect of soft measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

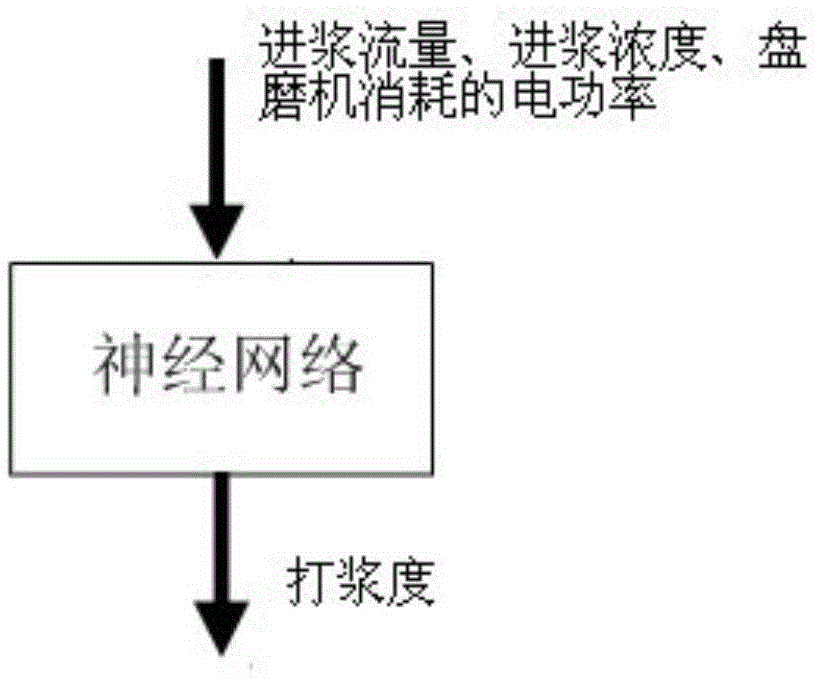

[0050] Such as figure 1 As shown, the present invention establishes the mapping relationship between the feed flow rate, the feed concentration, the electric power consumed by the disc refiner and the beating degree at the corresponding time, and establishes a neural network. After the neural network is trained, soft measurement is performed on the degree of beating.

[0051] To achieve this purpose, the following steps are specifically included:

[0052] 1) According to the historical detailed records of the production parameters of the pulp mill, the statistics of the incoming stock flow rate, incoming stock concentration, electric power consumed by the disc refiner, and the beating degree at the corresponding time; The electrical power consumed by the machine is used as an input parameter, and the degree of beating is used as an output par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com