Coordinated automatic control system and method for fully mechanized mining face equipment

An automatic control system and technology of fully mechanized mining face, applied in the field of coal mining, can solve problems such as waste of energy, delayed operation of workers, and unfavorable personal safety of workers, so as to eliminate delays and misjudgments, ensure personal safety, and reduce physical labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

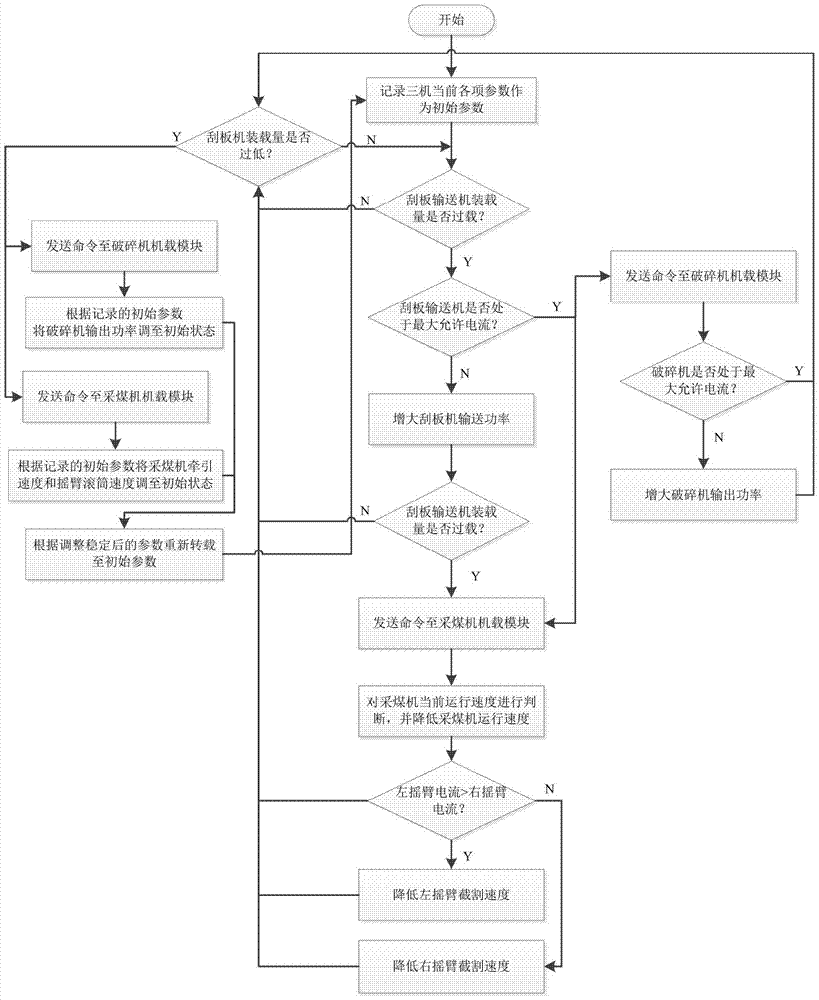

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

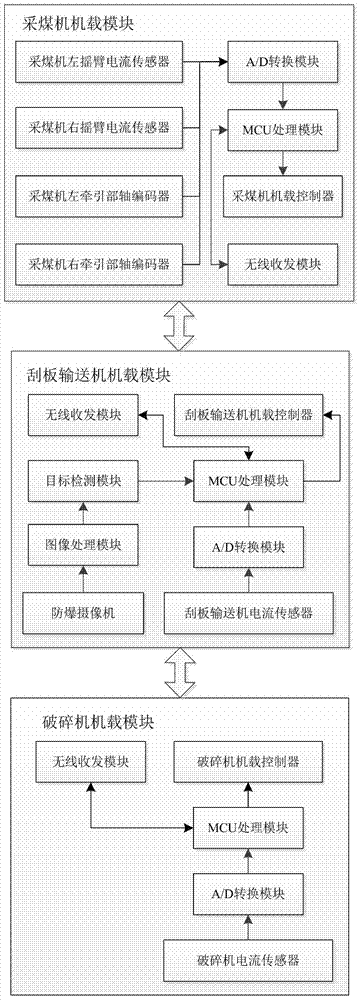

[0028] Such as figure 1 As shown, a cooperative automatic control system for fully mechanized mining face equipment, including the onboard module of the coal mining machine, the onboard module of the scraper conveyor and the onboard module of the crusher,

[0029] The airborne module of the shearer includes a current sensor for the left rocker arm of the shearer, a current sensor for the right rocker arm of the shearer, a shaft encoder for the left traction part of the shearer, a shaft encoder for the right traction part of the shearer, and an A / D The conversion module, the MCU processing module, the on-board controller of the shearer and the wireless transceiver module are mainly used for data collection and processing of various parts of the shearer, control of the work of the shearer, and communication connection with the scraper conveyor; The shearer lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com