Electronic component mounting substrate, method for manufacturing the electronic component mounting substrate, motor and air-conditioning apparatus,

A technology for electronic components and mounting substrates. It is used in the manufacture of motor generators, electrical components, and printed circuit manufacturing. It can solve problems such as poor operation of electronic components, increased residual stress, and failure of electronic circuits to operate normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

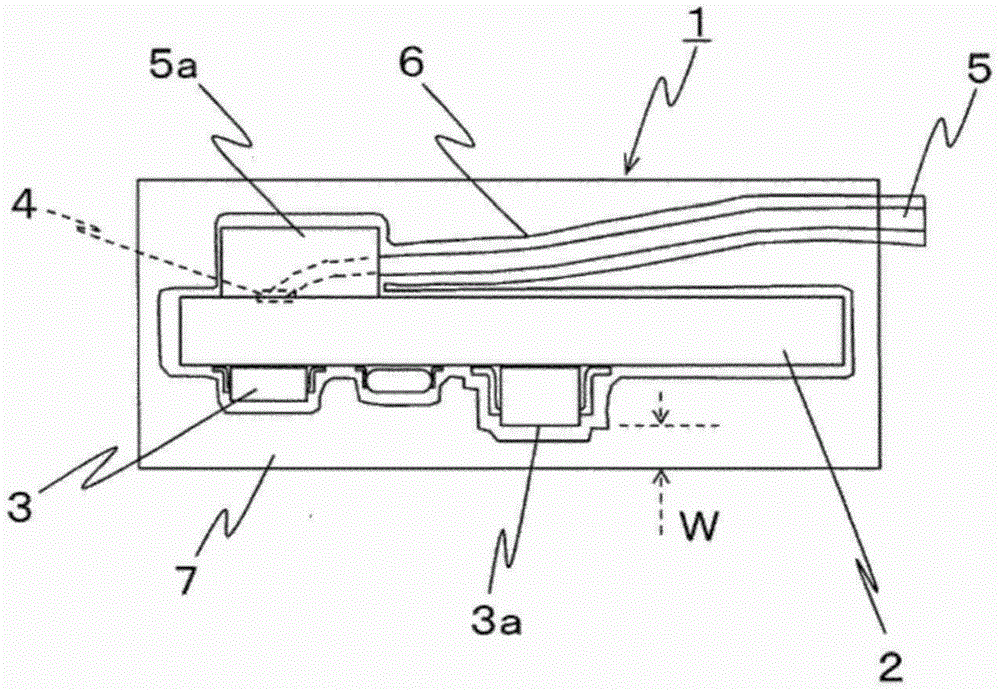

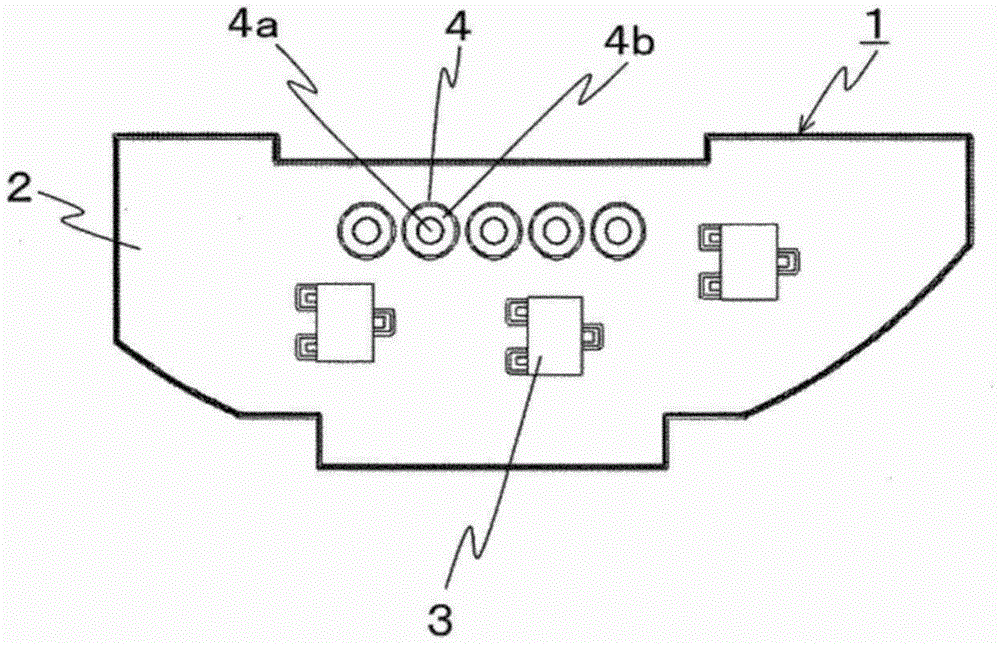

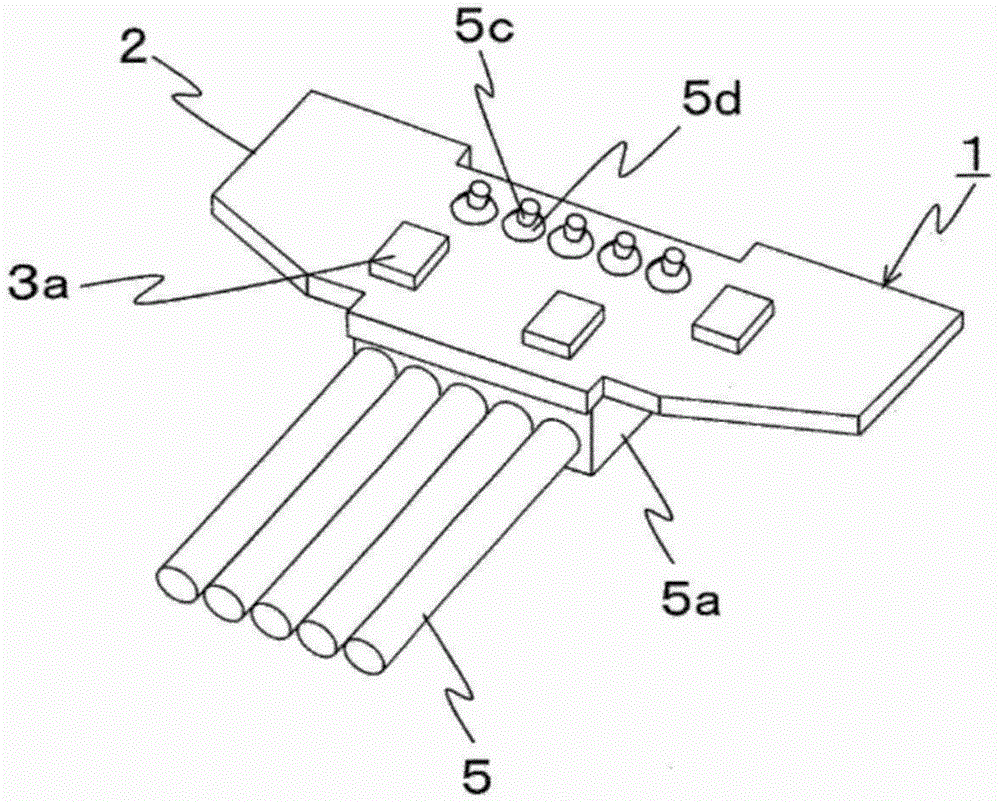

[0043] figure 1 It is a schematic cross-sectional view of the electronic component mounting board 1 of this embodiment. At least one electronic component 3 is mounted on the surface of the plate-shaped substrate 2 . Electronic component 3 is mounted on one or both surfaces of substrate 2 . exist Figure 1 ~ Figure 3 In the example of , the electronic component 3 is mounted on only one side of the substrate 2 . Hereinafter, for convenience of description, the surface on which the electronic component 3 is mounted is referred to as a component mounting surface. Electronic components 3 can be connected to each other by patterned conductive circuit wiring (not shown) on the surface of the substrate 2 to form an electronic circuit (not shown). The electrode portion 4 is electrically connected to the electronic component 3 directly or via the electronic circuit. A through hole 4 a penetrating the substrate 2 is formed in the center of the electrode portion 4 , and a metal foil ...

Embodiment approach 2

[0067] Figure 13 It is a figure which shows the air conditioner 40 provided with the electric motor 20. The air conditioner 40 includes an outdoor unit 41 and an indoor unit 42 connected to the outdoor unit 41 . The outdoor unit 41 and the indoor unit 42 include an evaporator, a condenser, a compressor, and an expansion mechanism (not shown), and constitute a refrigeration cycle system with these components. The outdoor unit 41 includes a blower 43 . The air blower 43 is provided with the electric motor 20 in Embodiment 1.

[0068] Since the air conditioner 40 of the present embodiment includes the motor 20, it can be operated normally even when the air conditioner 40 is used in a high-humidity environment. In addition, the motor 20 can be used not only for the air conditioner 40 but also for various devices such as a heat pump device (not shown), and the same effect can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com