Surface acoustic wave element and method of manufacturing the same

一种声表面波器件、制造方法的技术,应用在声表面波器件和声表面波器件的制造领域,能够解决部件发生异常等问题,达到提高可靠性、提升利润幅度、增强结合力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

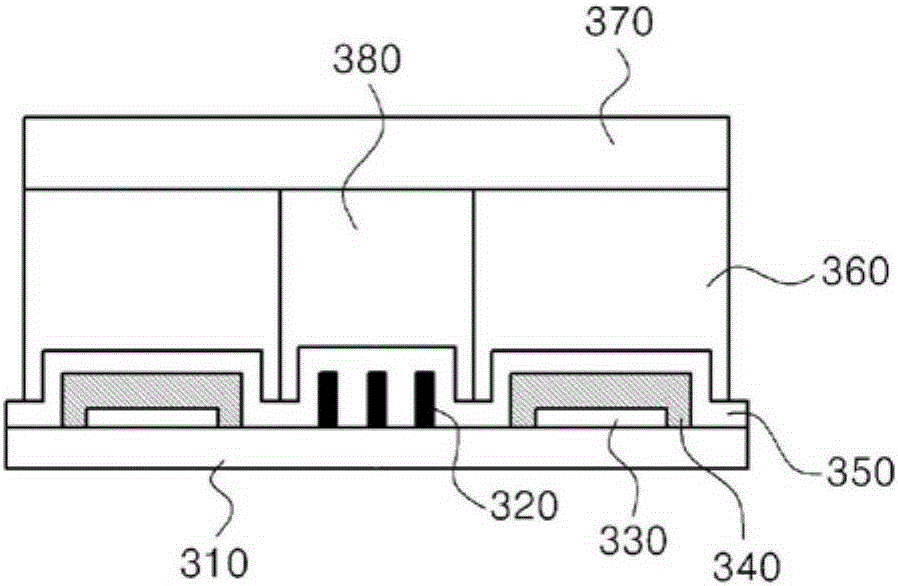

[0034] The purpose and technical concept of the present invention and the details of its application effect can be clearly understood through the following detailed description of the accompanying drawings of the specification of the present invention. Hereinafter, embodiments according to the present invention will be described with reference to the drawings.

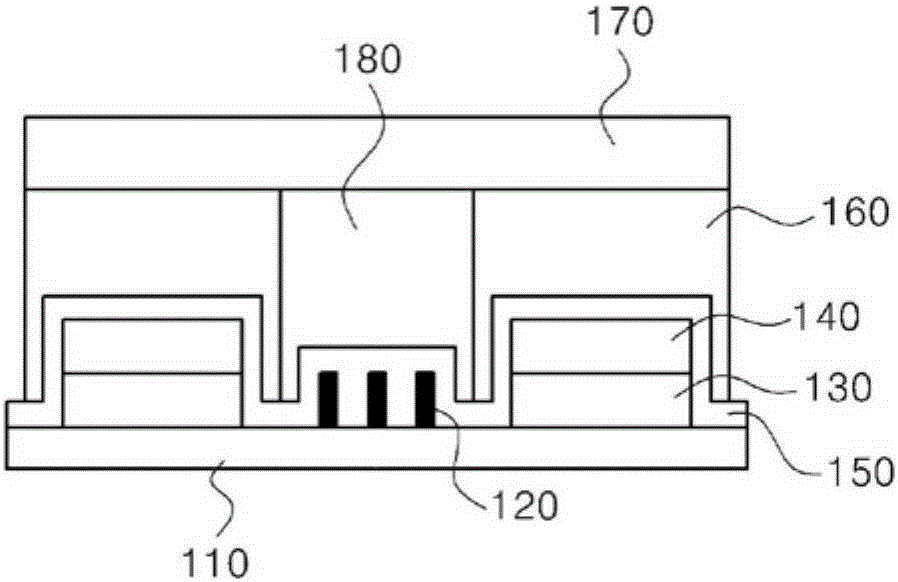

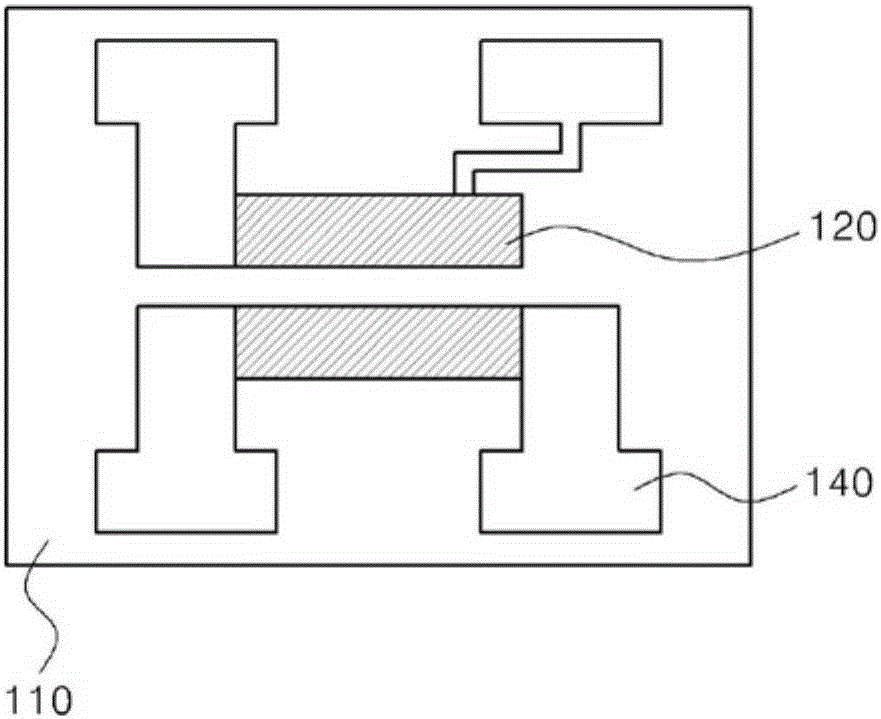

[0035] figure 1 , 2 It is a cross-sectional view and a perspective view schematically showing a surface acoustic wave device according to an embodiment of the prior art.

[0036] refer to figure 1 There is a method for manufacturing surface acoustic wave devices: using a wafer-level packaging method and using a photosensitive resin such as photoresist (PhotoResist) to seal the cavity (Cavity) on the piezoelectric element.

[0037] At this time, the surface acoustic wave device can include all kinds of machines that use surface acoustic wave (SAW), such as: surface acoustic wave filter, surface acoustic wave sensor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com