Continuous powder damp and hot sterilization equipment

A sterilization equipment and damp heat technology, applied in food science, food preservation, application, etc., can solve problems such as large investment, and achieve the effect of improving drying quality, low cost, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

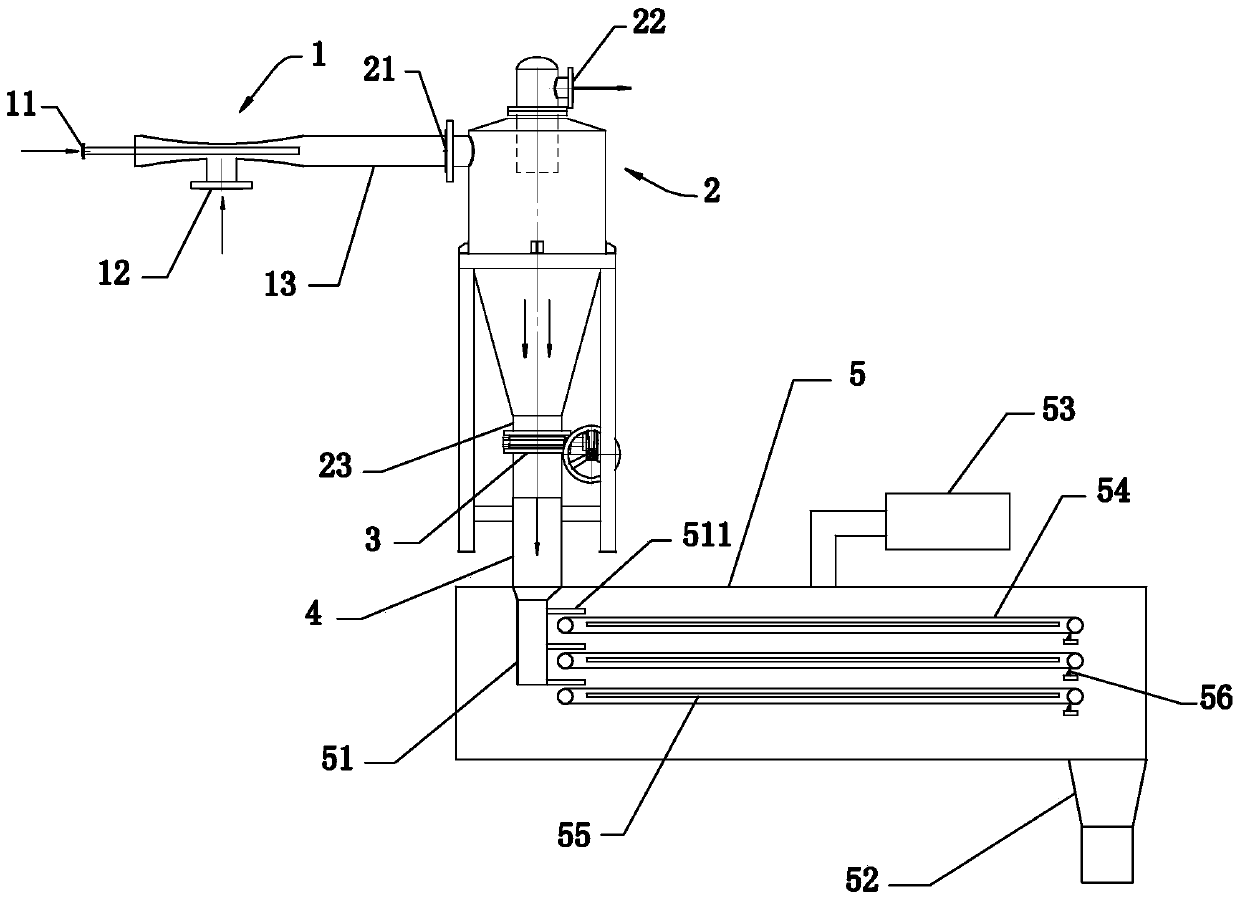

[0029] Such as figure 1 As shown, a continuous powder heat sterilization equipment includes a spray sterilization device, a separation device and a drying device, wherein the spray sterilization device includes a Venturi injector 1, and the Venturi injector 1 is provided with a high-temperature steam inlet 11, powder The material feed port 12 and the mixing chamber 13 are connected to the separation device, and the separation device is connected to the drying device.

[0030] In this embodiment, the separation device includes a cyclone separator 2, and the cyclone separator 2 is provided with a sterilizing material inlet 21, an air outlet 22 and a sterilizing material outlet 23, the sterilizing material inlet 21 is connected to the mixing chamber 13, and the sterilizing material outlet 23 is equipped with a related fan 3 , The discharge port of the shut-off fan 3 is connected with a material conveying pipeline 4, and the material conveying pipeline 4 is connected to the drying...

Embodiment 2

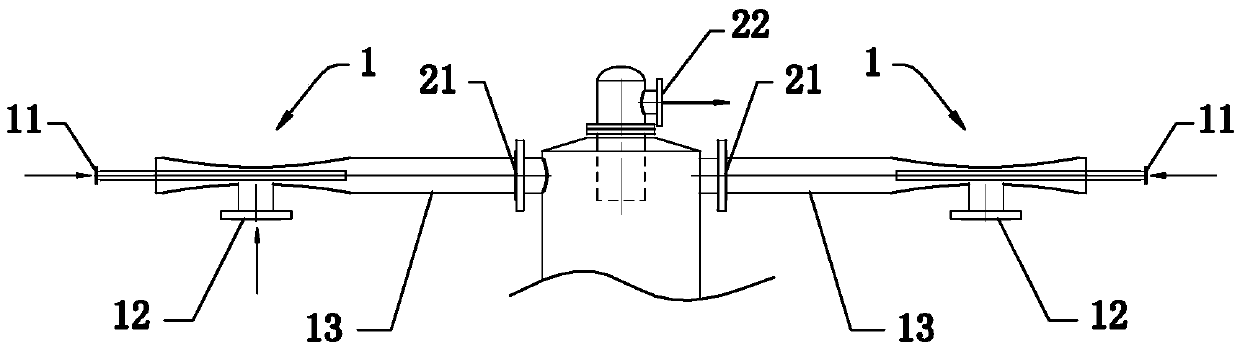

[0036] This embodiment has basically the same structure as Embodiment 1, and the difference is that at least two Venturi injectors 1 are provided, and the Venturi injectors 1 are connected in parallel, and the mixing chamber 13 is connected to the sterilized material of the cyclone separator 2 Import 21, specifically as figure 2 as shown, figure 2 Only the case where two Venturi injectors 1 are provided is shown.

[0037] The continuous powder moist heat sterilization equipment provided in this embodiment can greatly improve the sterilization efficiency.

Embodiment 3

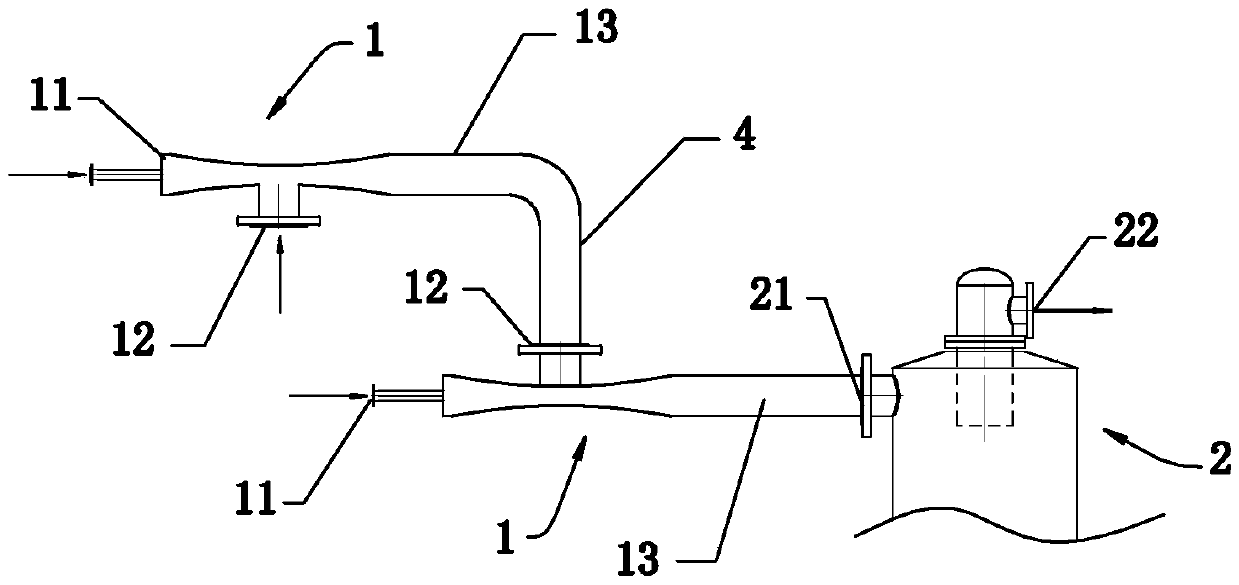

[0039] This embodiment has basically the same structure as Embodiment 1, the difference is that there are at least two Venturi injectors 1, the Venturi injectors 1 are connected in series, and the mixing chamber 13 of the upper-stage Venturi injector 1 is connected in series The powder material feed port 12 of the Venturi injector 1 adjacent to the lower stage in series is connected through the material conveying pipeline 4, and the mixing chamber 13 of the Venturi injector 1 at the tail end of the series is connected to the sterilizing material inlet 21 of the cyclone separator 2, specifically Such as image 3 as shown, image 3 Only the case where two Venturi injectors 1 are provided is shown.

[0040] The continuous powder moist heat sterilization equipment provided in this embodiment realizes multi-stage sterilization and can effectively improve the quality of sterilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com