Efficient reverse-osmosis concentrated water treatment method

A high-efficiency reverse osmosis and reverse osmosis concentrated water technology, applied in the field of high-efficiency reverse osmosis concentrated water treatment, can solve the problems of difficult industrial implementation, high operating costs, and complex processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

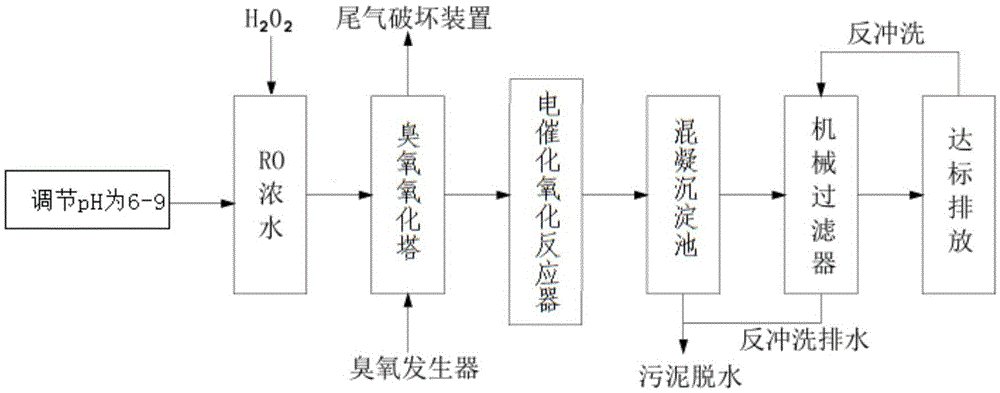

[0029] like figure 1Shown, a kind of efficient reverse osmosis concentrated water treatment method of the present invention comprises the following steps:

[0030] 1) Adjust the pH range of reverse osmosis concentrated water to 6-9;

[0031] 2), adding H to reverse osmosis concentrated water 2 o 2 , control H 2 o 2 The concentration is 70-400mg / L, and the reaction is 5-20 minutes; the dosage of H2O2 depends on the reactivity of the target organic pollutants in the sewage and ozone, and the H2O2 is preferentially added before entering the ozone oxidation tower. 2 o 2, Accelerated O 3 Decomposition produces highly active hydroxyl radicals, which react with orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com