A compound flame-retardant mineral powder and flame-retardant asphalt mixture for tunnel asphalt pavement

An asphalt pavement and mineral powder technology, which is applied in the field of flame retardant asphalt, can solve the problems of less attention to the flame retardant and smoke suppression performance and road performance of asphalt pavement, and achieves lower combustion heat and smoke emission rate, low price, and improved resistance. flammable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

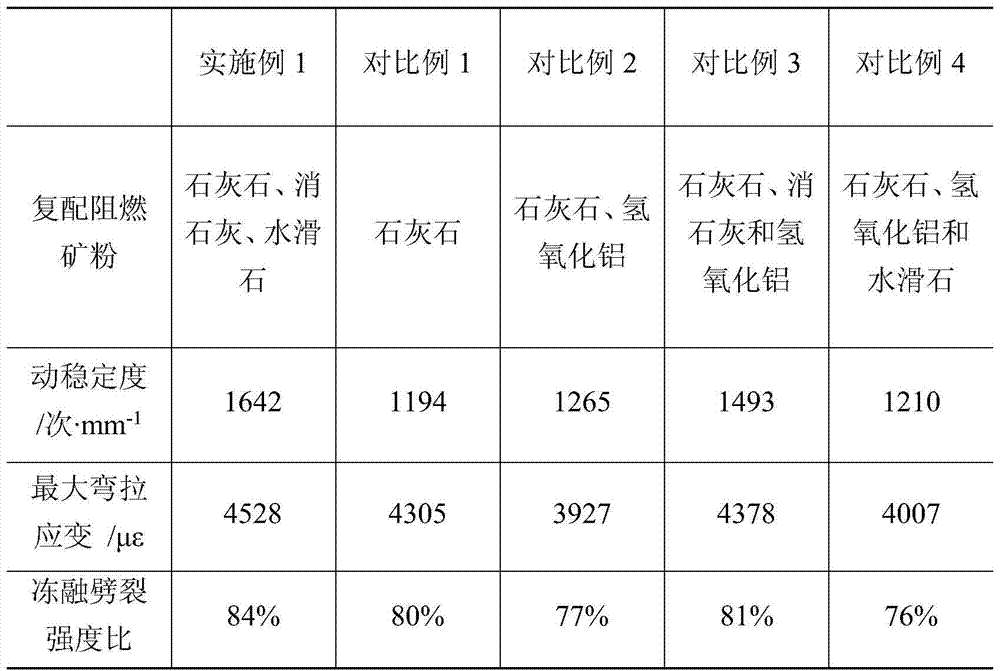

Examples

Embodiment 1

[0038] The flame-retardant asphalt mixture is composed of coarse aggregate, fine aggregate, asphalt, and compound flame-retardant mineral powder. The mass ratio is coarse aggregate: fine aggregate: asphalt: compound flame-retardant mineral powder = 100:20:5.0: 5.2.

[0039] The coarse aggregate is basalt; the fine aggregate is basalt; the asphalt is No. 70 A grade road petroleum asphalt.

[0040] The compound flame retardant mineral powder is compounded by limestone, slaked lime and hydrotalcite with a mass ratio of 60:25:15.

[0041] Described slaked lime selects 1250 mesh slaked lime for use, median diameter 8 μm, Ca(OH) 2 The purity is 95%; the specific surface area of the hydrotalcite is 80m 2 / g.

[0042] Heat the asphalt to 160°C, add it to the aggregate at 180°C and mix for 90 seconds, then add the compound flame-retardant mineral powder at the same time, mix for 90 seconds again, and then go through the molding process to obtain the flame-retardant asphalt concret...

Embodiment 2

[0073] The compound flame retardant mineral powder is composed of limestone, slaked lime and hydrotalcite, and the mass ratio is limestone:slaked lime:hydrotalcite=60:20:20.

[0074] Described slaked lime selects 1250 mesh slaked lime for use, median diameter 8 μm, Ca(OH) 2 95% purity;

[0075] The specific surface area that described hydrotalcite selects is 80m 2 / g;

[0076] The fire-retardant asphalt mixture for tunnels is composed of coarse aggregate, fine aggregate, asphalt, fiber, and compound flame-retardant mineral powder. The mass ratio is coarse aggregate: fine aggregate: asphalt: fiber: compound flame-retardant mineral powder = 100 :20:4.8:0.2:5.1. The coarse aggregate is basalt; the fine aggregate is basalt; the asphalt is SBS modified asphalt; and the fiber is basalt fiber.

[0077] The production adopts a batch-type asphalt mixing plant. Before production, the compound flame-retardant mineral powder is mixed evenly according to the proportion and then pumped ...

Embodiment 3

[0079] The compound flame retardant mineral powder is composed of limestone, slaked lime and hydrotalcite-like, and the mass ratio is limestone:slaked lime:hydrotalcite-like=70:20:10. The raw materials are selected according to the above ratio, mixed and stirred to obtain a compound flame-retardant mineral powder.

[0080] Described slaked lime selects 800 mesh slaked lime for use, median diameter 15 μ m, Ca(OH) 2 90% purity;

[0081] The specific surface area of the selected hydrotalcite is 120m 2 / g;

[0082] The flame-retardant asphalt mixture is composed of coarse aggregate, fine aggregate, asphalt, and compound flame-retardant mineral powder. The mass ratio is coarse aggregate: fine aggregate: asphalt: compound flame-retardant mineral powder = 100:20:5.5: 5.7. The coarse aggregate is basalt; the fine aggregate is basalt; the asphalt is SBS modified asphalt.

[0083] The production adopts a batch-type asphalt mixing plant. Before production, the compound flame-retar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com