Preparation method of antistatic highly-flame-retardant MC nylon composite material

A nylon composite material, high flame-retardant technology, applied in the field of polymer materials, can solve problems such as air pollution and personnel poisoning, achieve the effects of inhibiting combustion, reducing heat, and enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

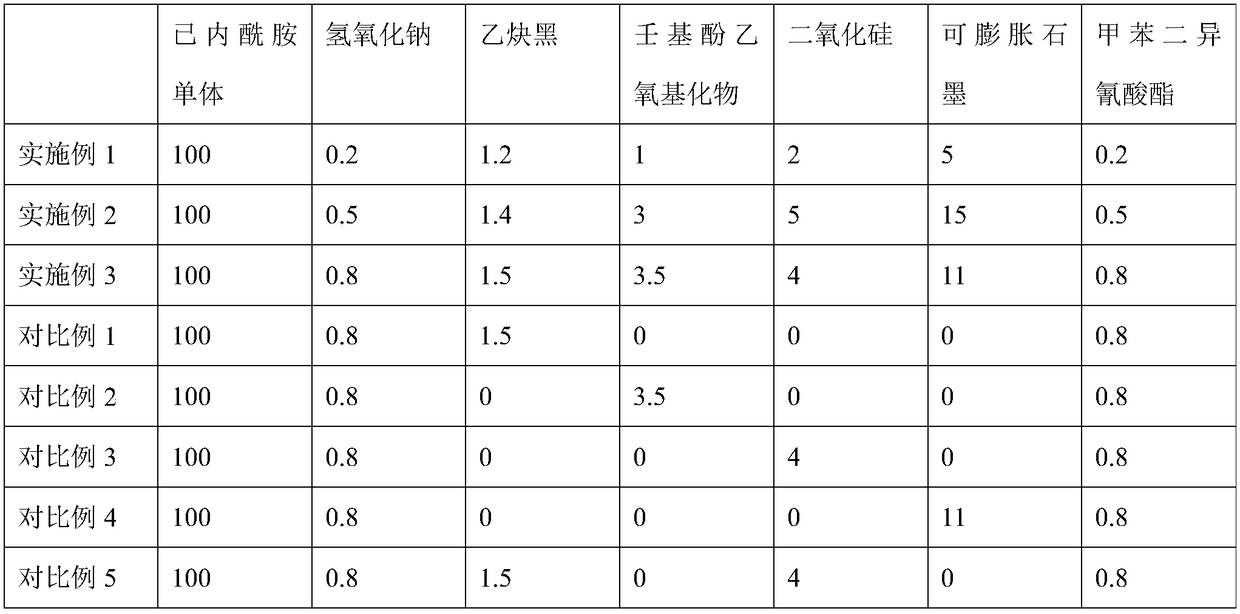

Embodiment 1-3

[0026] A preparation method of antistatic high flame-retardant MC nylon composite material, comprising the steps of:

[0027] (1) According to the parts by weight, heat 100 parts of caprolactam monomer in the reaction vessel to 120°C to melt the material, add sodium hydroxide for 0.6h of vacuum dehydration, and continue vacuum dehydration for 0.8h; remove the vacuum, and add in order Acetylene black, nonylphenol ethoxylate, silicon dioxide and expandable graphite, increase the temperature of the reaction solution to 145°C, stir and disperse for 0.6h with a twin-shaft double-blade low-speed dispersing mixer with a rotation speed of 100rpm, and then continue to dehydrate and vacuumize for 1h , vacuum dehydration (absolute) pressure is less than 5mmHg;

[0028] (2) After releasing the vacuum, add toluene diisocyanate to ultrasonically disperse for 15 minutes, cast the reaction solution into a mold preheated to 165°C, keep warm and spin the mold centrifugally for 30 minutes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com