Production system for novel filtering material non-woven fabric

A technology of filter material and production system, applied in non-woven fabrics, textiles and papermaking, spinneret assemblies, etc., can solve the problems of small market demand, thin thickness, and inability to use low-pressure differential filtration equipment, etc., to solve the problem of production Difficulty, the effect of improving breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

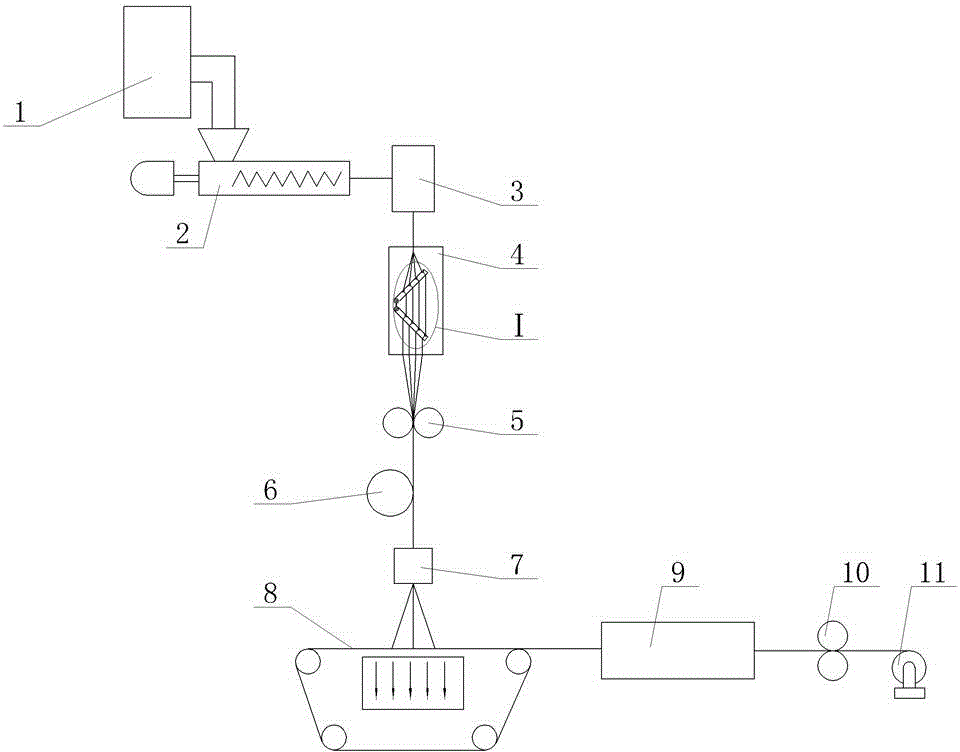

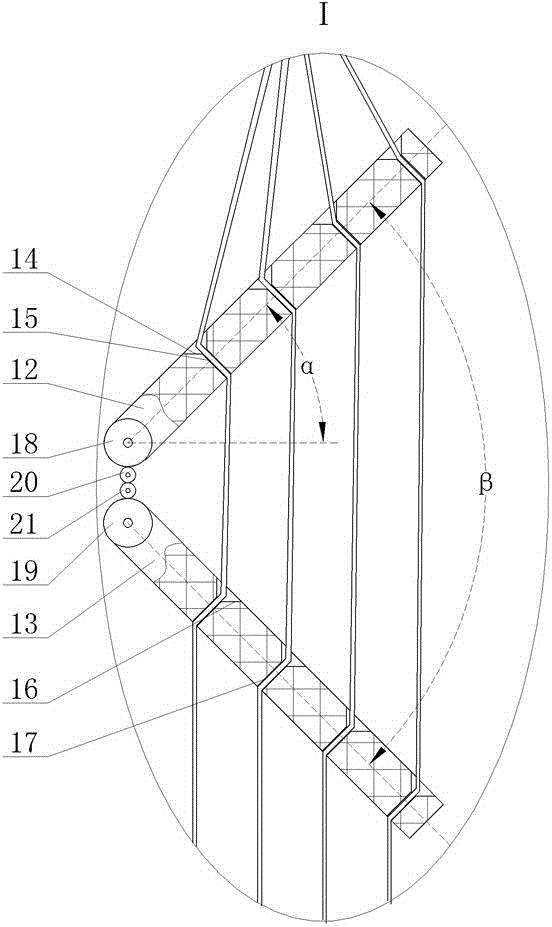

[0009] A new type of non-woven fabric production system for filter materials, including drying tower 1, screw extruder 2, precision filter 3, spinning box 4, tension roller 5, stretching roller 6, air stretching system 7, forming Net machine 8, heat setting machine 9, cooling roll 10 and winding roll 11, the discharge port of drying tower 1 is connected with the feed port of screw extruder 2, and the discharge port of screw extruder 2 is connected with precision filter 3 , the precision filter 3 is located above the spinning box 4, the tension roll 5, the stretching roll 6, the air stretching system 7 and the web forming machine 8 are located below the spinning box 4 from top to bottom, the heat setting machine 9, the cooling The roll 10 and the winding roll 11 are located in front of the web forming machine 8 in turn, and the first spinneret 12 and the second spinneret 13 are respectively arranged in the spinning box 4, and several first connection holes are evenly opened on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com