Single beam dynamic focusing method

A dynamic focusing and single-beam technology, applied in optics, optical components, instruments, etc., can solve problems such as limited extraction efficiency and reduced device output capacity, and achieve the effects of high degree of realizability, easy operation, and multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

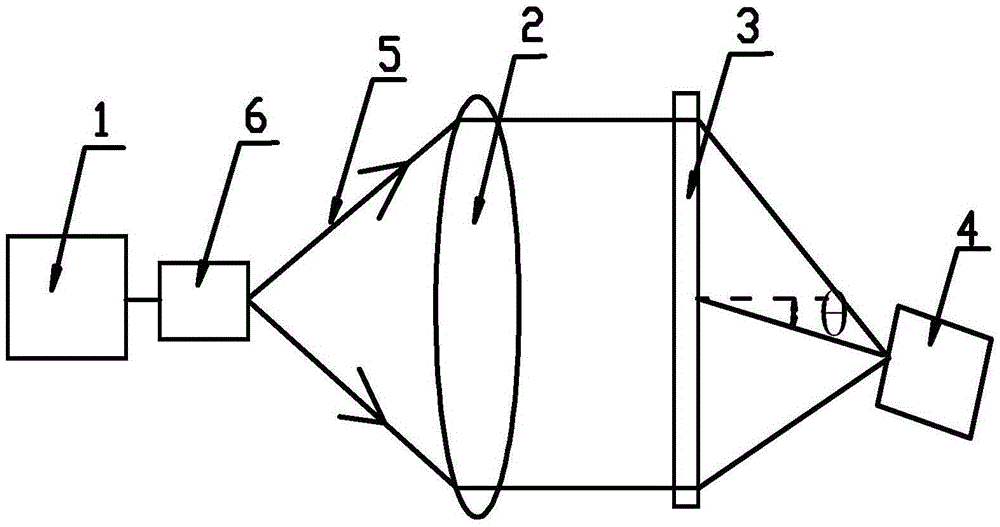

[0037] like figure 1 As shown, a single-beam dynamic focusing method includes emitting a laser pulse 5 from a laser source 1, and the laser pulse 5 is expanded into parallel light through a lens 2, and the parallel light is focused on a target pill through a holographic grating 3 to realize dynamic focusing In the process, the laser source 1, lens 2 and holographic grating 3 are arranged in a coaxial structure, and single-beam dynamic focusing is adopted, which avoids the problem of precise time control of each sub-pulse by dynamic focusing of beams, is easy to operate, and can achieve a high degree of optimization. High, and at the same time, the laser pulse 5 is not spliced by sub-pulses, and there is no problem of short pulse amplification and saturation reducing the output capability of the laser system.

[0038] The wavelength of the laser pulse 5 is increasing, the wavelength of the laser pulse 5 is λ, and the λ is determined by λ 1 increase to λ 2 , and 0.5nm≤λ 2 -...

Embodiment 2

[0053] In this embodiment, the same parts as those in Embodiment 1 will not be repeated, but the difference is:

[0054] In this embodiment, in order to match the compression change process of the target capsule, the design size of the focal spot at the target capsule is required to be reduced from 415.796 μm to 226.461 μm, and the focal spot is reduced by 45.5%.

[0055] The beam aperture of the laser pulse 5 is 36mm × 36mm, the size of the holographic grating 3 is 40mm × 40mm, and its effective light aperture D=45.664mm, which adopts λ 0 =1053nm laser pulse 5 is recorded, according to geometric optics and beam aperture of laser pulse 5, beam spatial arrangement factor, preferred f 0 = 400mm.

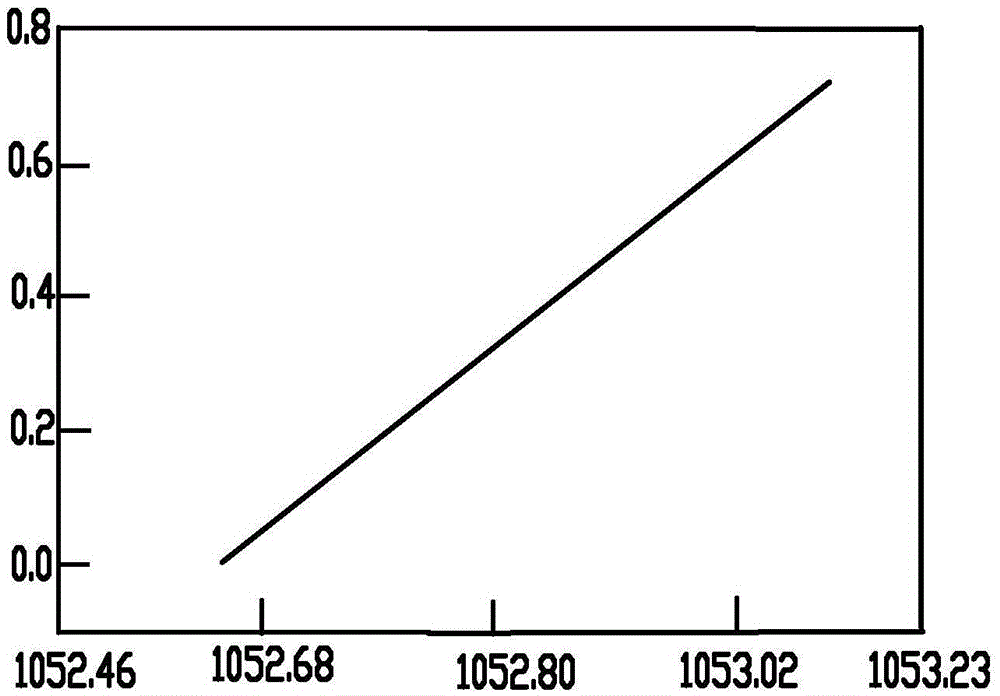

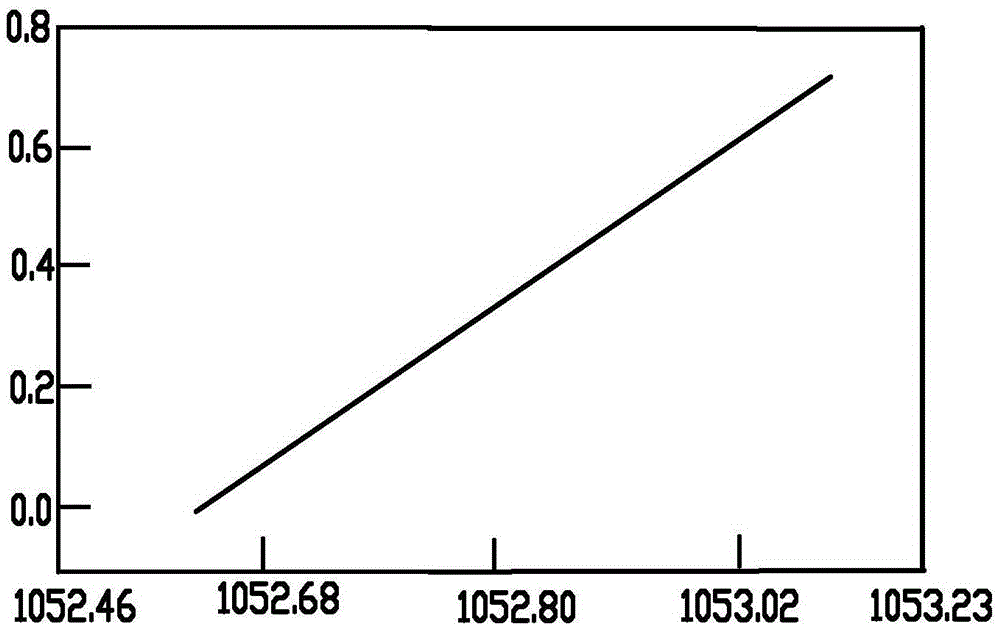

[0056] Depend on get λ 1 =1052.462nm,λ 2 =1053.23nm, the compression change time of the target pellet is 3ns, then the phase modulation frequency of the phase modulator is 0.256nm / ns, then the wavelength of the laser pulse 5 increases from 1052.462nm to the required time of 1053.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com