Novel air-cooled motor based on heat pipe heat-conduction technology

An air-cooled motor and heat pipe technology, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of complex processing technology of the casing, reduce the power density ratio, increase the difficulty of sealing, etc., and reduce accidental entry into the motor. risk, reduce thermal resistance, and improve the strength of the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below.

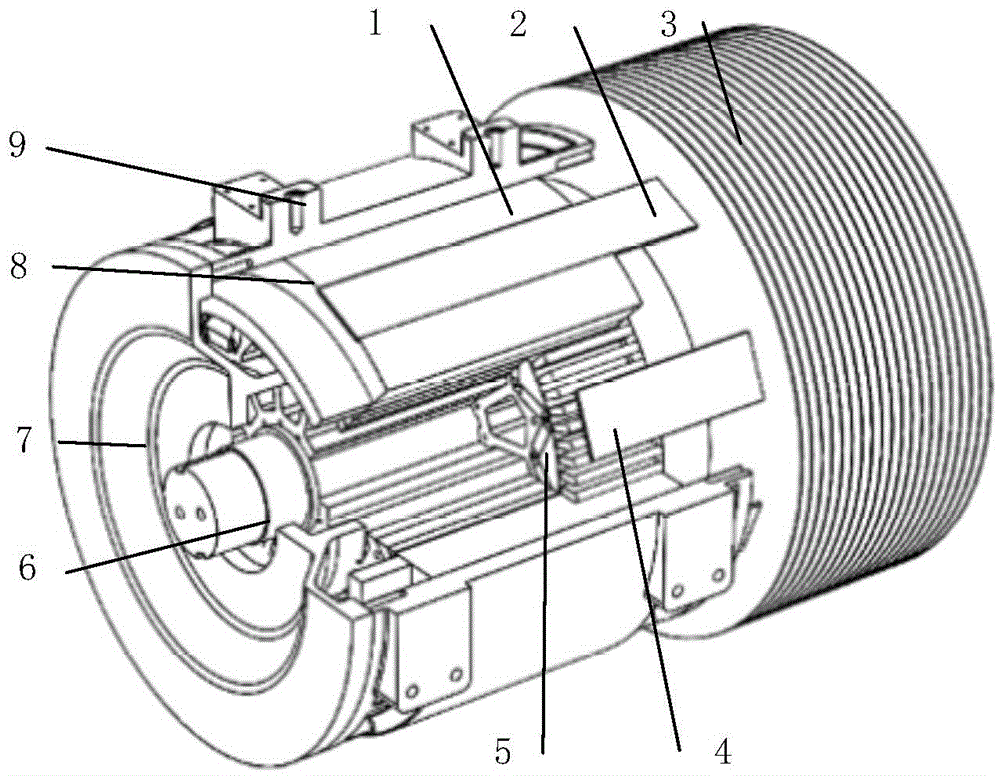

[0030] A new type of air-cooled motor based on heat pipe heat transfer technology, modified on the basis of permanent magnet synchronous motor, including shaft, stator, rotor, heat pipe, fin group, magnetic steel, winding, end cover, machine base.

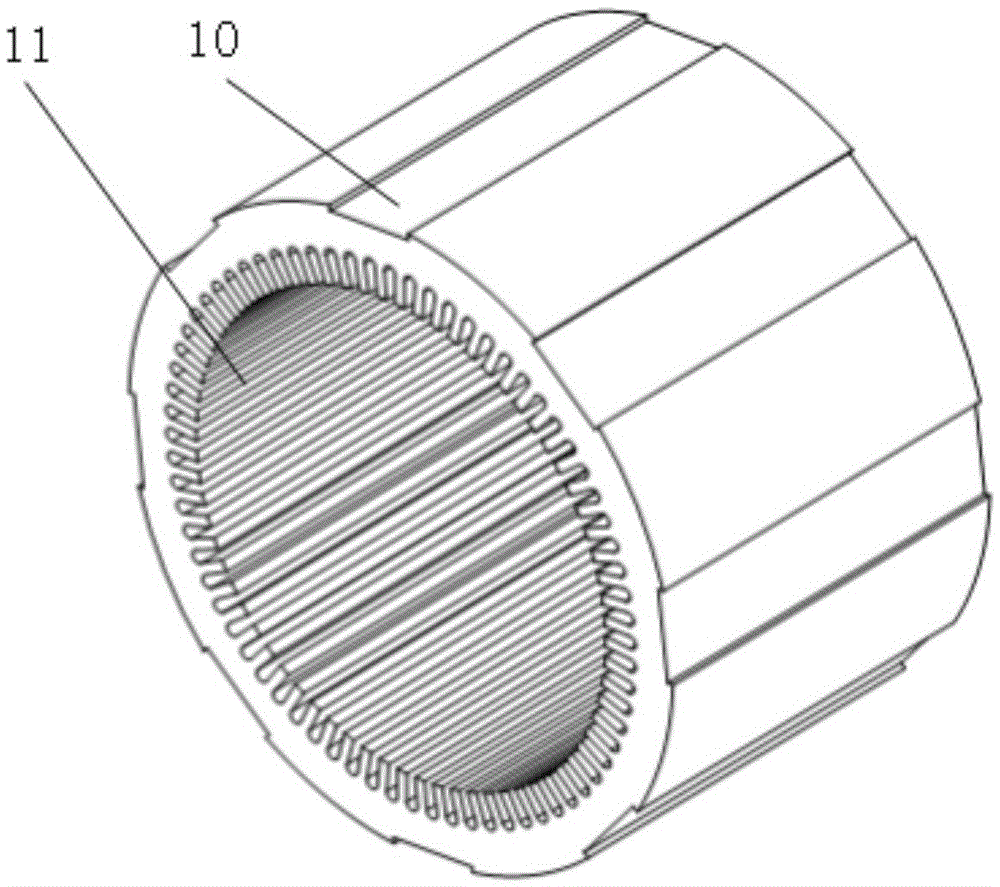

[0031] The shaft drives the rotor to rotate, the magnetic steel is fixed on the rotor, the stator is set around the rotor, the winding is fixed on the stator, the base is set around the stator, the end of the base is an end cover, and the shaft passes through the end cover. There are multiple heat pipes arranged evenly along the same circumference, and the heat pipes are aluminum heat pipes. The installation groove is located on the outer wall of the stator, and is a rectangular groove axially penetrating the stator, and one end of the heat pipe is welded in the installation groove. The other end of the heat pipe is welded on the fin set. The fins can be ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com