Force sensor data collection system and method based on EtherCAT

A data acquisition system and force sensor technology, applied in transmission systems, digital transmission systems, data exchange networks, etc., can solve the problems of high price, inability to connect to the Internet, and difficult to directly interface with the host controller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

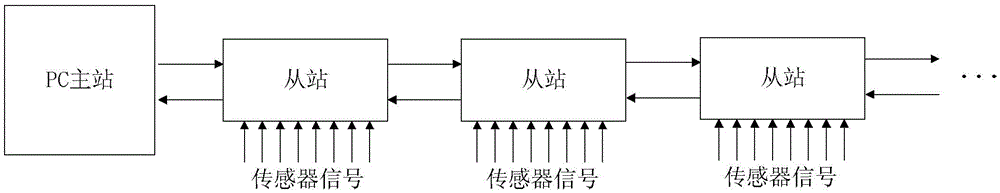

[0034] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, a kind of force sensor data acquisition system based on EtherCAT of this embodiment, comprises:

[0035] PC master station and multiple slave stations supporting EtherCAT protocol;

[0036] Wherein, each of the slave stations is connected to a plurality of sensor devices;

[0037] Each of the slave stations is connected in series through the MII interface, and the whole connected in series is connected with the PC master station through the EtherCAT bus;

[0038] An Ethernet card supporting the EtherCAT protocol is installed on the PC master station, and the PC master station is connected to one of the slave stations through the Ethernet card.

[0039] The effect of this implementation mode:

[0040] The purpose of this embodiment is to provide an EtherCAT-based force sensor data acquisition system for the deficiencies of the prior art. An EtherCAT-based force sensor data acqui...

specific Embodiment approach 2

[0050] Embodiment 2: This embodiment differs from Embodiment 1 in that: the slave station encapsulates the information of the on-site sensor device and sends it to the PC master station, and the PC master station monitors the information of the slave station.

[0051] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

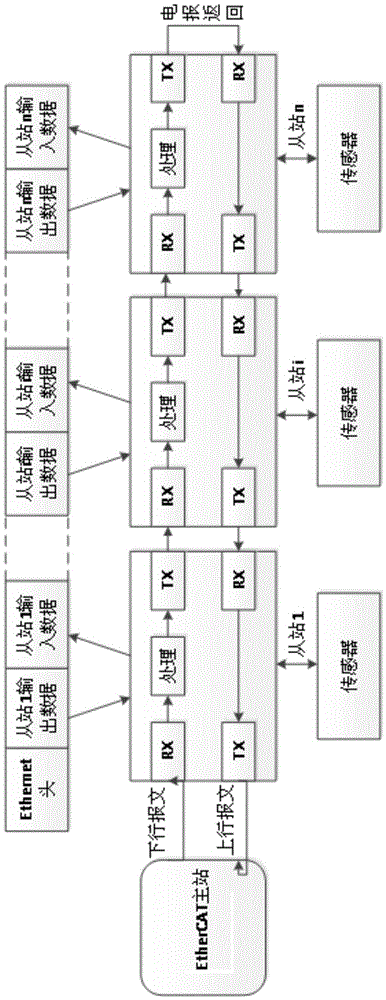

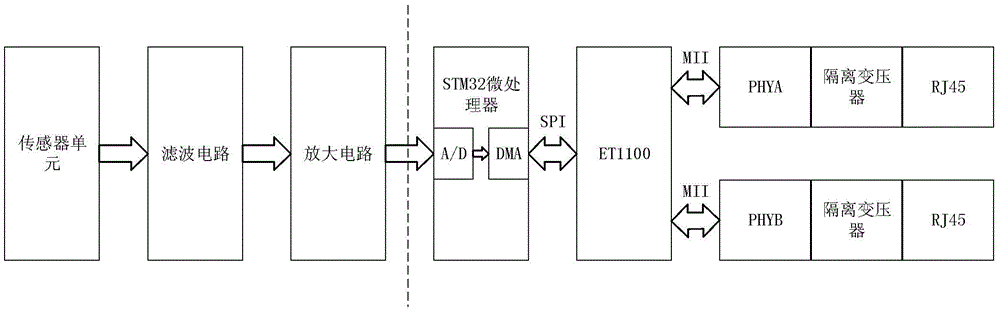

[0052] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that each slave station includes: EtherCAT communication subsystem and data acquisition subsystem;

[0053] Wherein, the EtherCAT communication subsystem realizes the EtherCAT data link layer and physical layer control on the one hand, processes the EtherCAT frame, and carries out data exchange with the EtherCAT master station; The control and data sending and receiving process of the application device;

[0054] Wherein, the data acquisition subsystem collects and processes the sensor data, and then transmits it to the EtherCAT communication subsystem.

[0055] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com