A protection device and method for titanium and titanium alloy additive manufacturing based on a welding process

A technology of additive manufacturing and welding technology, which is applied in the direction of manufacturing tools, welding equipment, welding accessories, etc., can solve the problems of long duration, limited movement path of robot, and inability to protect, and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, but it is not a limitation to the implementation of the present invention.

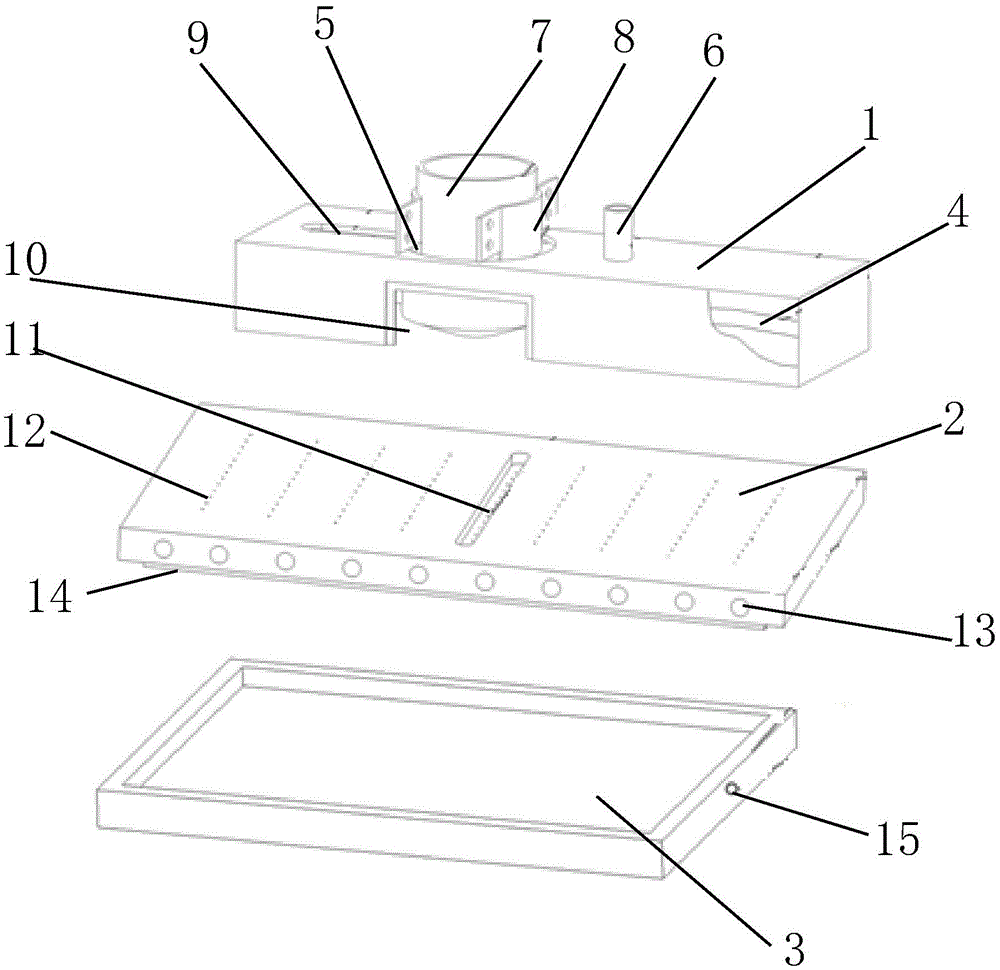

[0026] Such as figure 1 As shown, the present invention provides a protection device for additive manufacturing of titanium and titanium alloys based on welding technology, which includes a protection tow cover 1, an upper protection base 2 and a lower protection base 3 arranged in sequence from top to bottom .

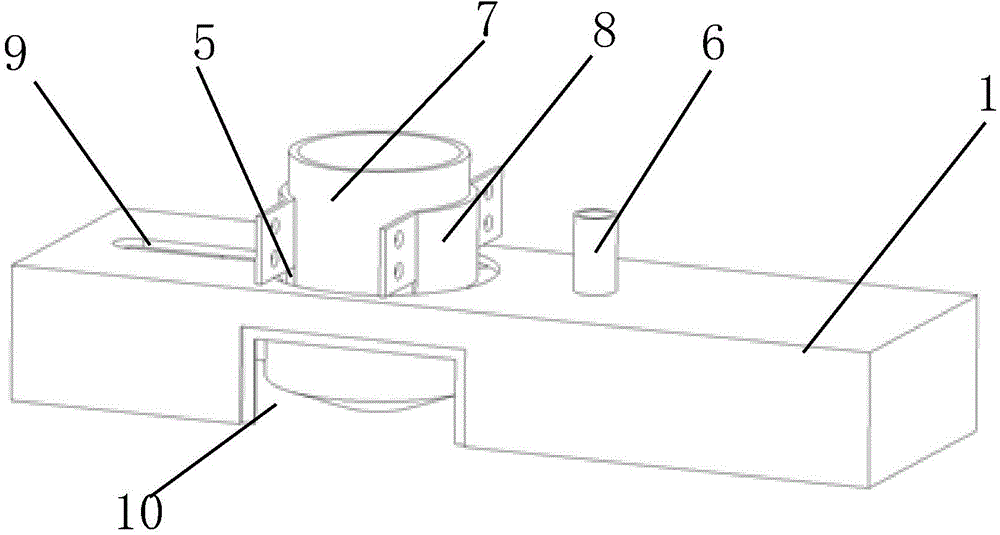

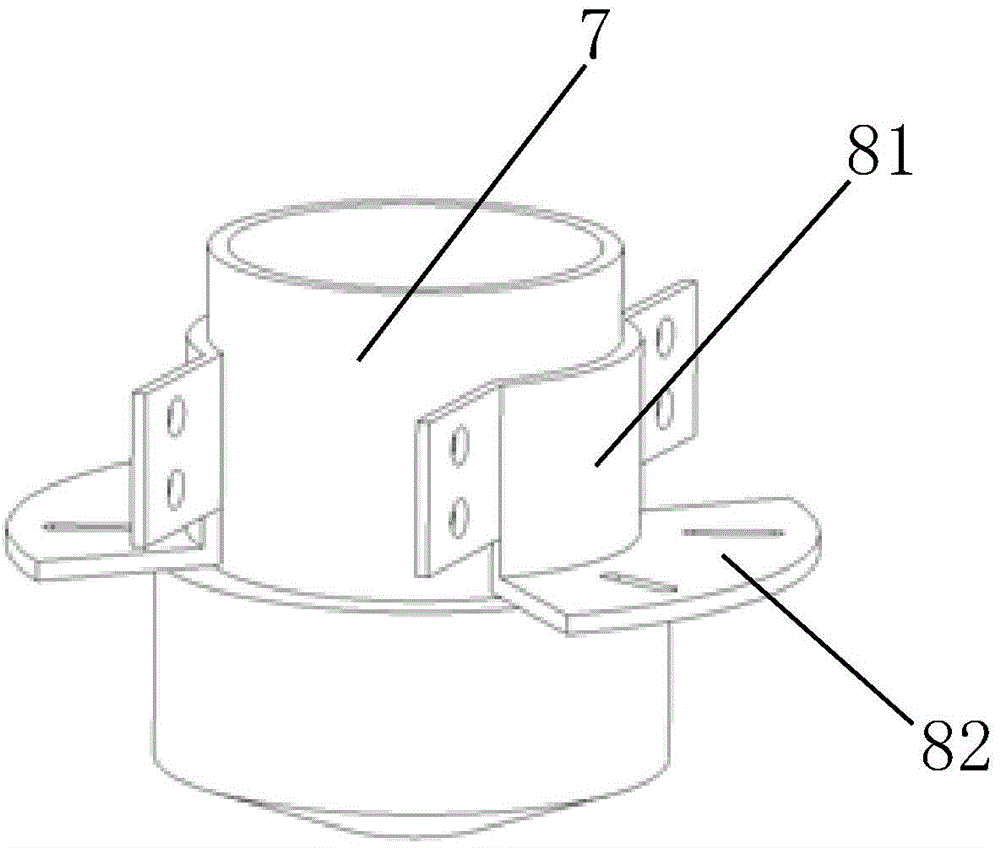

[0027] Such as figure 2 , image 3 As shown, the protective drag cover 1 is a rectangular cover with an open bottom, and the open bottom is covered with a layer of copper mesh 4 with a certain density, which can disperse the incoming protective gas and effectively promote the uniformity of protection. . The top surface of the cover body is provided with a welding torch mouth 5 and an air supply channel opening 6 , and a welding torch buckle 8 for clamping the welding torch 7 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com