Co-combustion preparation method of chlorine doped graphene quantum dots

A graphene quantum dot, chlorine doping technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of cumbersome steps in mass production of graphene quantum dots, unsuitable for mass production, etc., and achieve good use value. , excellent optoelectronic properties, the effect of changing the structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

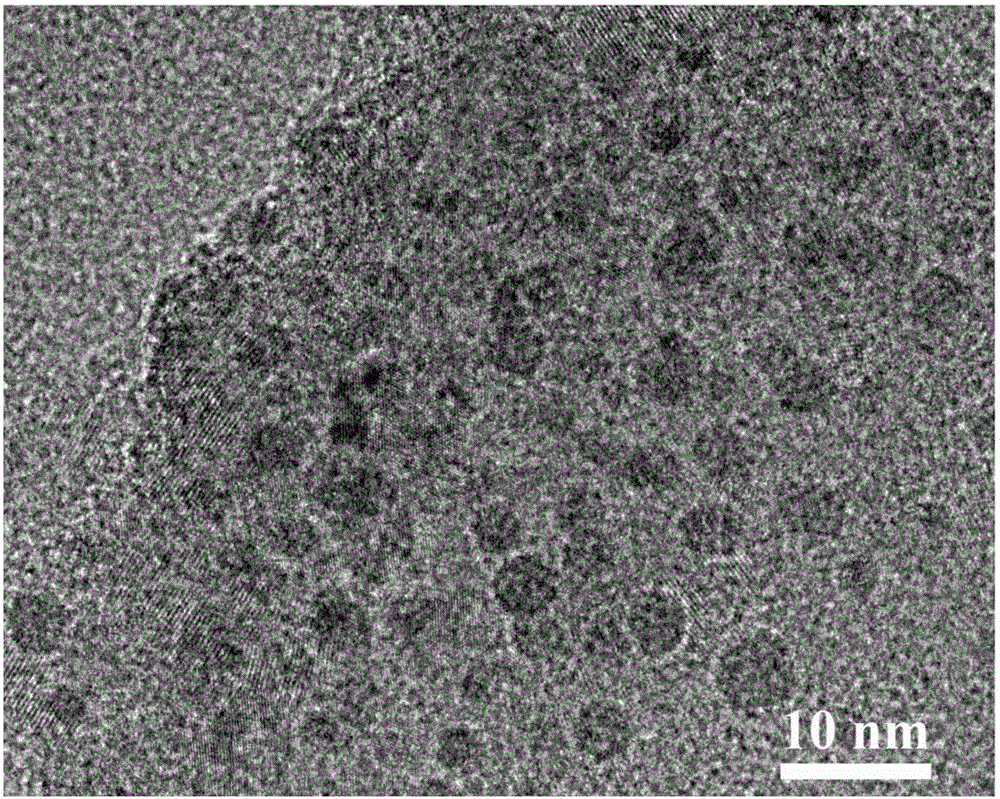

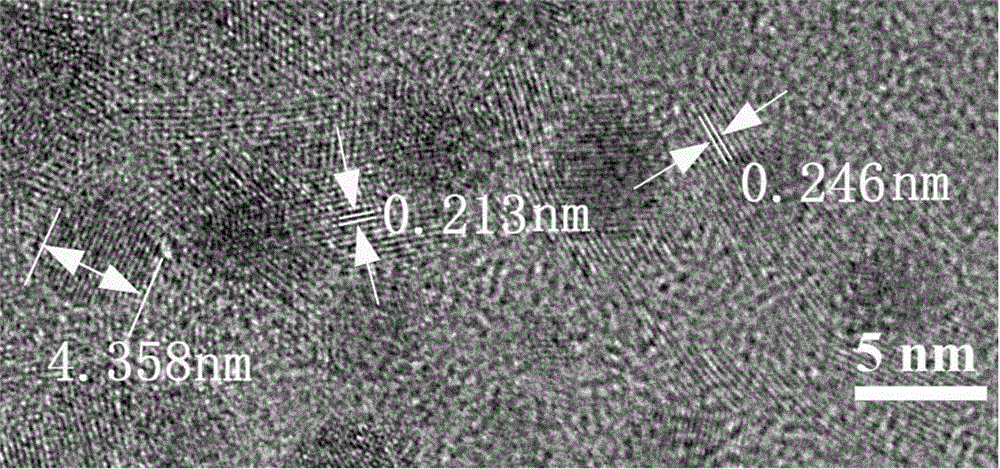

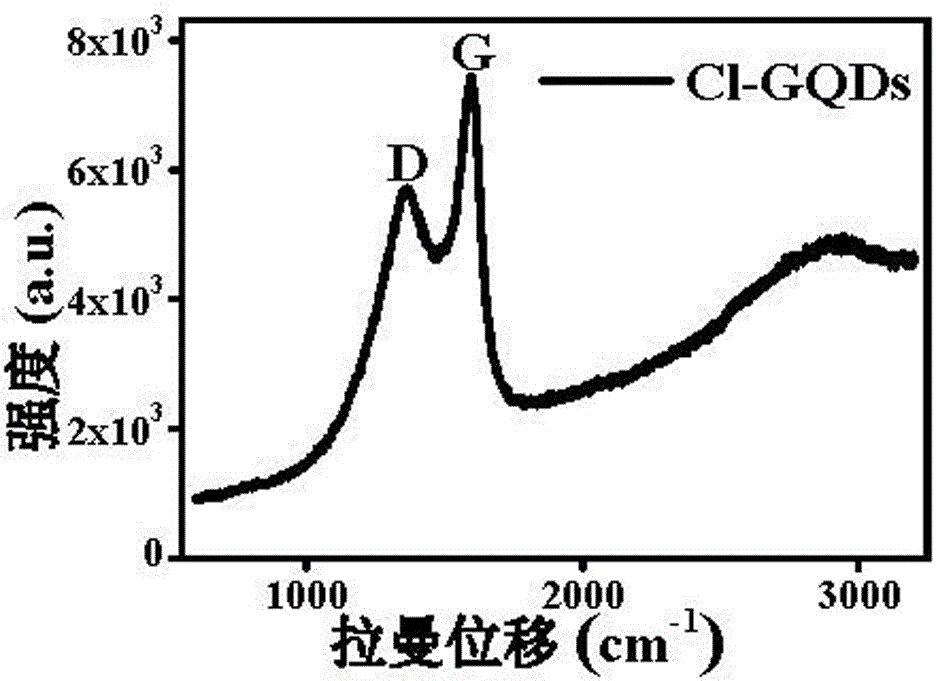

[0029] Example 1: A co-combustion preparation method of chlorine-doped graphene quantum dots, through the doping of heterogeneous chlorine atoms, to effectively modulate the structure and energy level of graphene quantum dots, thereby modulating the photoelectric properties of graphene quantum dots , the chlorine-doped graphene quantum dots are obtained by co-combustion, ultrasonic and other preparation methods:

[0030] (1) Co-combustion: take 10g of liquid paraffin and 1.6g of carbon dichloride with a straw, mix them evenly, put them into a clean pure white cotton wick bottle and ignite them, and use tweezers to clamp the clean glass carrier at 25-30cm above the flame Collect the chlorine-doped carbon nanospheres produced in the combustion process, and collect all the chlorine-doped carbon nanospheres on the glass slide after the combustion is extinguished;

[0031] (2) Ultrasonic liquid phase exfoliation: Add a dispersant to the chlorine-doped carbon nanospheres. The disper...

Embodiment 2

[0033] Example 2: A co-combustion preparation method of chlorine-doped graphene quantum dots, through the doping of heterogeneous chlorine atoms, to effectively modulate the structure and energy level of graphene quantum dots, thereby modulating the photoelectric properties of graphene quantum dots , the chlorine-doped graphene quantum dots are obtained by co-combustion, ultrasonic and other preparation methods:

[0034] (1) Co-combustion: Take 5g of liquid paraffin and 0.8g of carbon dichloride with a straw, mix them evenly, put them into a clean pure white cotton wick bottle and ignite them, and use tweezers to clamp the clean glass carrier at 25-30cm above the flame Collect the chlorine-doped carbon nanospheres produced in the combustion process, and collect all the chlorine-doped carbon nanospheres on the glass slide after the combustion is extinguished;

[0035] (2) Ultrasonic liquid phase exfoliation: Add a dispersant to the chlorine-doped carbon nanospheres. The dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com