A pressure reducing device and method for a supercritical water system

A depressurization device, supercritical water technology, applied in chemical instruments and methods, water pollutants, special compound water treatment, etc. , The effect of avoiding valve failure problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

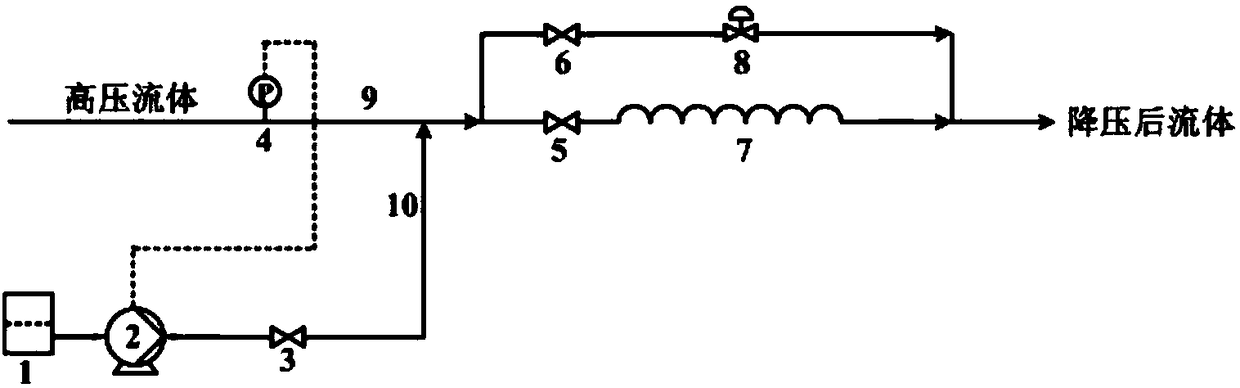

[0032] Such as figure 1 As shown, the decompression system includes a decompression branch, a start-stop branch and a resistance water branch. The decompression branch includes a capillary pressure reducer 7 , the inner diameter of which is in the range of 1-10 mm, and the capillary pressure reducer 7 is connected to the second cut-off valve 5 . The start-stop branch includes a first regulating valve 8 connected to the third cut-off valve 6 . The step-down branch and the start-stop branch are connected in parallel. The resistance water branch includes a resistance water storage tank 1 , the outlet of the storage tank 1 is connected to the inlet of the resistance water pump 2 , the outlet of the resistance water pump 2 is connected to the first stop valve 3 , and the first stop valve 3 is connected to the resistance water connection pipe 10 . After the supercritical water oxidation reaction, the high-pressure fluid flows into the post-reaction liquid pipe 9, and the outlet of...

Embodiment 2

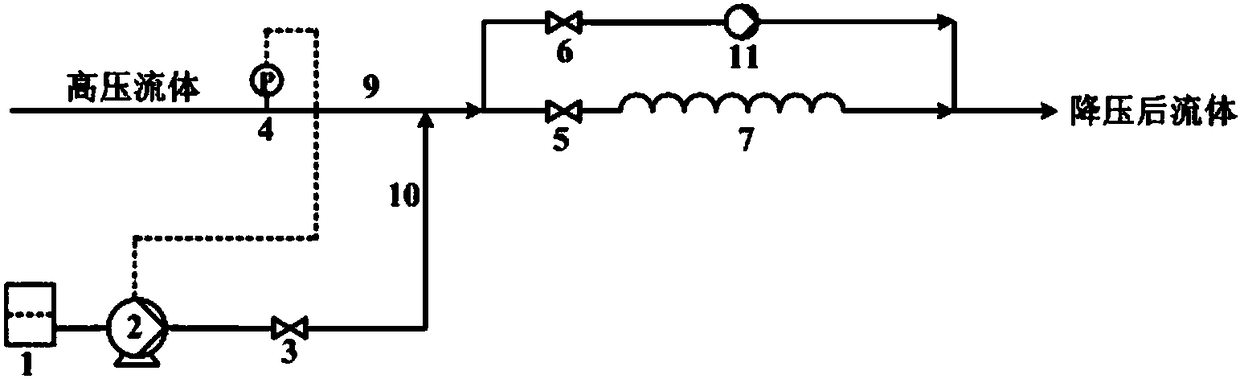

[0036] Such as figure 2 As shown, the first regulating valve 8 in Embodiment 1 is replaced by a back pressure regulating valve 11 . System pressure control during system startup and shutdown is realized by adjusting the back pressure valve.

[0037] The step-down process is as follows:

[0038]During the start-up stage of the system, the resistance water pump 2 is not started, the second cut-off valve 5 of the step-down branch is closed, and the third cut-off valve 6 of the start-stop branch is opened. As the system is filled with water, gradually adjust the back pressure valve 11 to gradually increase the system pressure to the set operating pressure. Open the second cut-off valve 5 of the step-down branch, close the third cut-off valve 6, and at the same time turn on the resistance water pump 2, so that the resistance water flows through the capillary 7, and gradually increase the flow of the water pump until the system pressure rises to the set working pressure. During ...

Embodiment 3

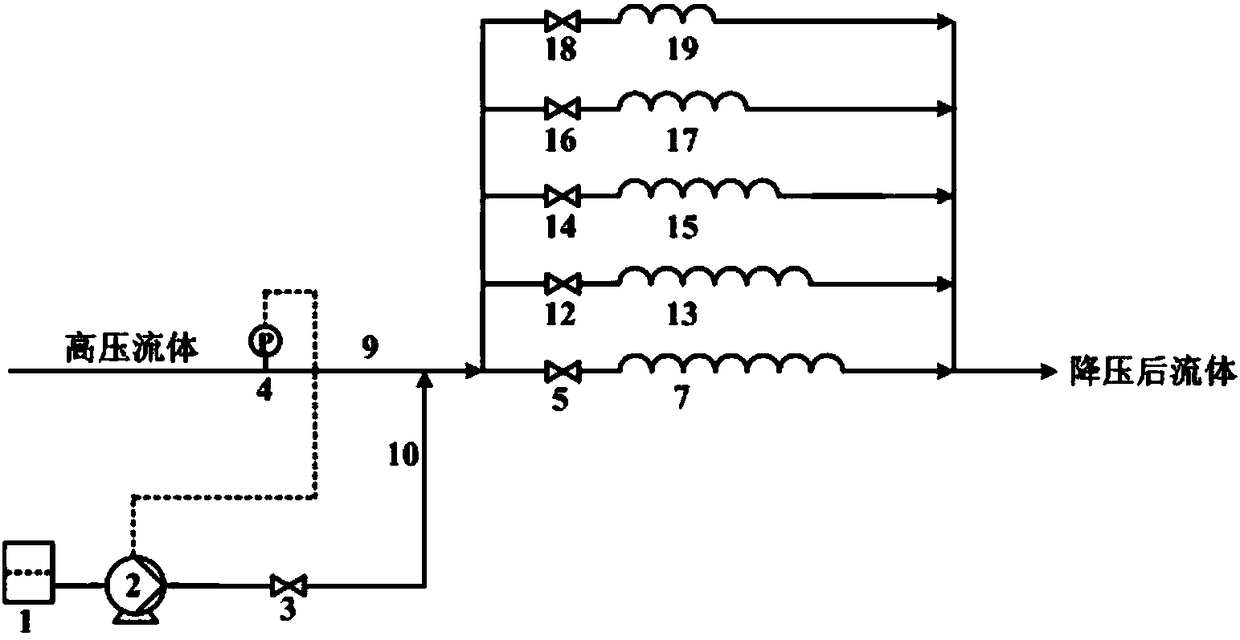

[0040] Such as image 3 As shown, the first regulating valve 8 in Embodiment 1 is replaced by a group of first capillary tube 13 , second capillary tube 15 , third capillary tube 17 and fourth capillary tube 19 connected in parallel with increasing lengths in sequence. System pressure control during system startup and shutdown is achieved by switching different capillary branches.

[0041] The step-down process is as follows:

[0042] During the start-up phase of the system, the resistance water pump 2 is not started, and the second cut-off valve 5 , the fourth cut-off valve 12 , the fifth cut-off valve 14 and the sixth cut-off valve 16 are closed. Open the seventh shut-off valve 18, and gradually increase the reactor pressure to the set operating pressure I as the system is filled with water. Open the sixth shut-off valve 16 and close the seventh shut-off valve 18 until the reactor pressure gradually rises to the set operating pressure II. Open the fifth shut-off valve 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com