ETN-DNT eutecticevaporate energetic material and preparation method thereof

A kind of eutectic, stabilizer technology, applied in the direction of aromatic nitration composition, etc., can solve the problems such as loss of effectiveness of gunpowder, deterioration of safety performance of gunpowder, change of gunpowder formula and composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

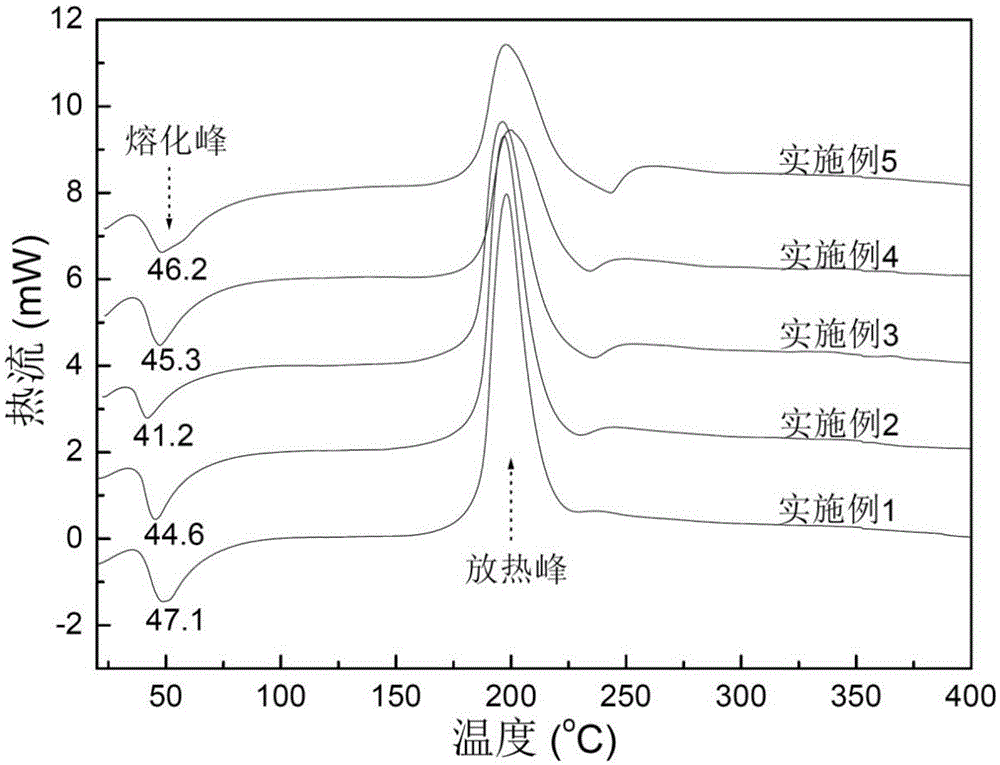

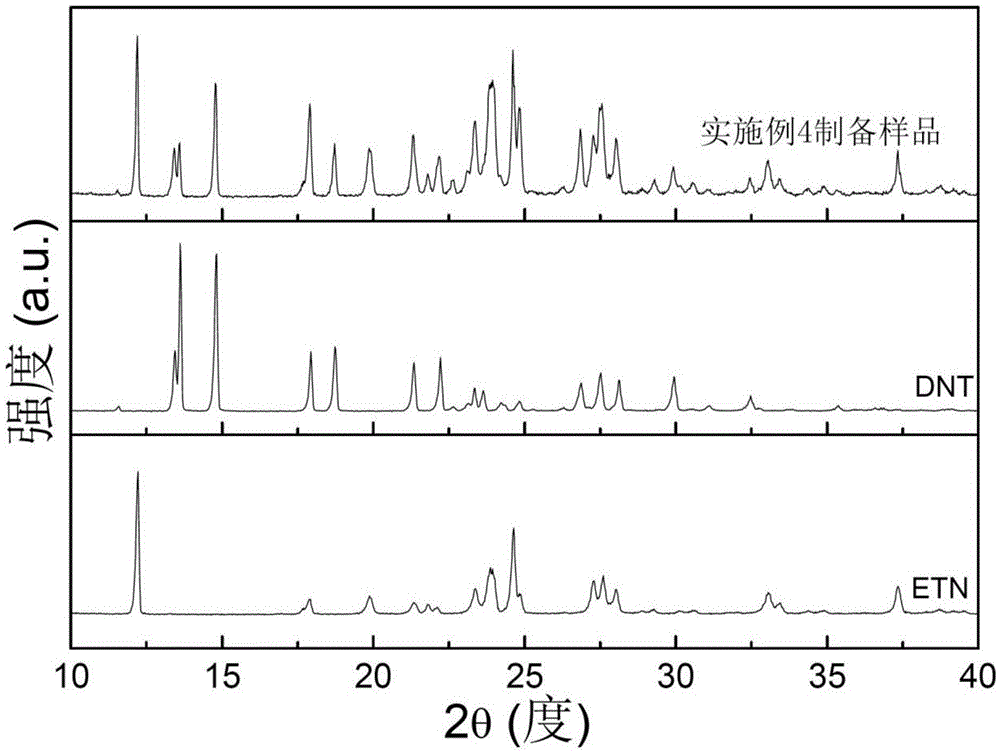

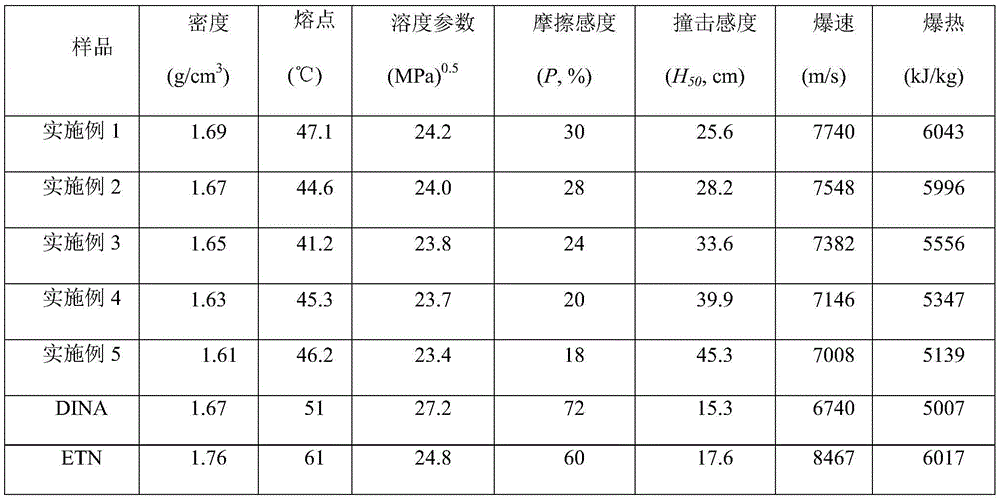

[0023] Take 1.21g of 1,2,3,4-butanetetraol tetranitrate (ETN) and 0.41g of 2,4-dinitrotoluene (DNT) into a beaker, put them in a 70°C water bath, and wait until the mixture is completely melted and dissolved , add 0.036g of 2-nitrodiphenylamine, 0.018g of diethyldiphenyl urea and 0.126g of dioctyl sebacate (DOS), stir to make all substances dissolve completely, and form a clear solution. Cool slowly to obtain ETN-DNT eutectic energetic material.

Embodiment 2

[0025] Take 2.07g of 1,2,3,4-butanetetraol tetranitrate (ETN) and 1.05g of 2,4-dinitrotoluene (DNT) into a beaker, put them in a water bath at 80°C, and wait until the mixture is completely melted and dissolved , add 0.034g of 2-nitrodiphenylamine, 0.034g of diethyldiphenylurea and 0.204g of dimethyl phthalate (DMP), stir to make all the substances dissolve completely, and form a clear solution. Slowly cooling under the temperature of 100°C, the ETN-DNT eutectic energetic material is obtained.

Embodiment 3

[0027] Take 2.97g of 1,2,3,4-butanetetraol tetranitrate (ETN) and 2.02g of 2,4-dinitrotoluene (DNT) into a beaker and put them in a 90°C water bath. After the mixture is completely melted and mutually soluble, add 0.056g of 2-nitrodiphenylamine, 0.112g of diethyldiphenylurea and 0.448g of dioctyl sebacate (DOS), stir to make all substances completely soluble in each other, and form a clear solution, keep warm Stop heating after 15 minutes, and cool slowly at room temperature to obtain ETN-DNT eutectic energetic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com