Polyaspartic acid composite hydrogel and preparation method thereof

A technology of composite hydrogel and polyaspartic acid, applied in the field of polyaspartic acid composite hydrogel and its preparation, can solve the problem of expensive polysuccinimide and high cost of polyaspartic acid hydrogel question

- Summary

- Abstract

- Description

- Claims

- Application Information

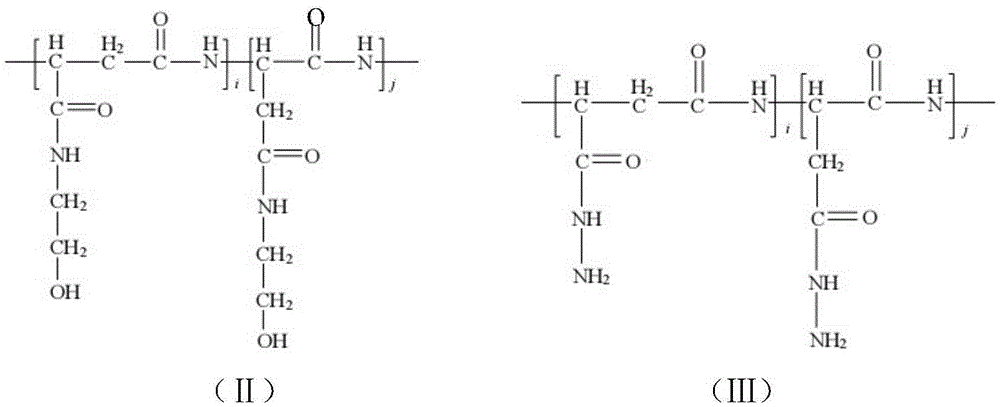

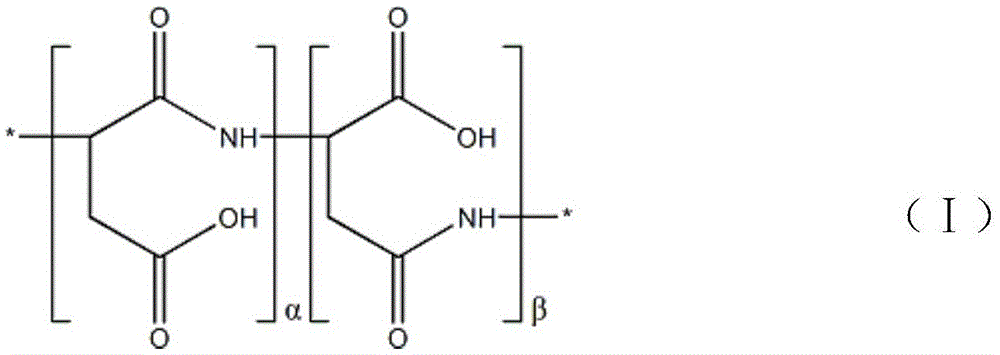

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

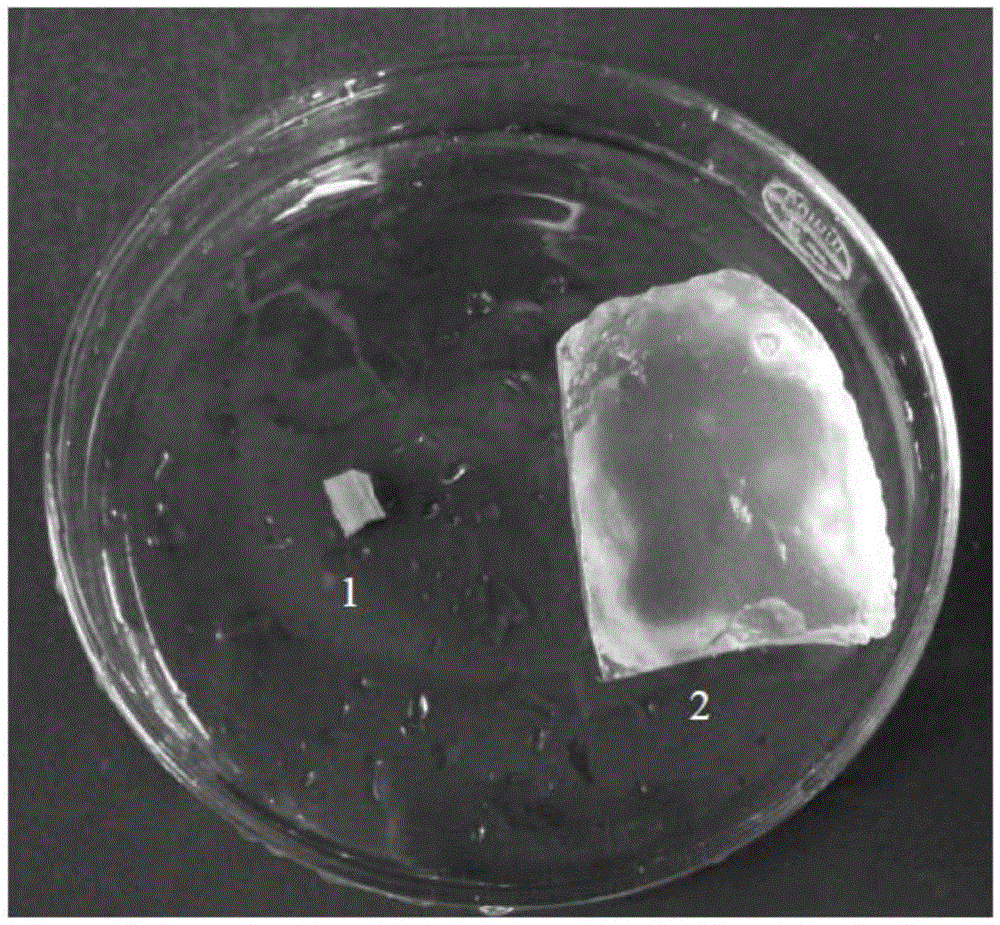

[0051] Example 1: Preparation of polyaspartic acid composite hydrogel.

[0052] (1) Mixing the biomass raw material suspension with the polyaspartic acid polymer aqueous solution to prepare a biomass raw material-polyaspartic acid mixture.

[0053] Add 6g of polyaspartic acid with a molecular weight of 50,000Da in a reactor with a stirring device, and mix it in deionized water until the concentration of the polyaspartic acid aqueous solution is 2mol / l; in a reactor with a stirring device Add soybean meal according to the mass ratio of soybean meal and polyaspartic acid as 1:5, then add deionized water and mix until the concentration of soybean meal suspension is 33.3g / L. The above polyaspartic acid aqueous solution and the soybean meal suspension are mixed to form a soybean meal-polyaspartic acid mixture, and after being fully stirred, the pH value of the solution is adjusted to 4.8 with phosphoric acid.

[0054] (2) Adding a cross-linking agent to the biomass raw material-po...

Embodiment 2

[0060] The difference between embodiment 2 and embodiment 1 is that the mass ratio of soybean meal and polyaspartic acid is 1:2.5, other conditions are all the same as embodiment 1, and under the same measurement conditions as embodiment 1, the tea bag method is used to measure The water absorption rate of the obtained polyaspartic acid composite hydrogel in 0.9% physiological saline is 225g / g; the elastic modulus G' of the hydrogel measured by a rheometer is 2857Pa.

Embodiment 3

[0062] The difference between embodiment 3 and embodiment 1 is that the mass ratio of soybean meal to polyaspartic acid is 1:2, all the other conditions are the same as in embodiment 1, and under the same measurement conditions as in embodiment 1, the tea bag method is used to measure The water absorption rate of the obtained polyaspartic acid composite hydrogel in 0.9% physiological saline is 218g / g, and the elastic modulus G' of the hydrogel measured by a rheometer is 2934Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Water absorption rate | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com