Hydrocarbon material hydrogenation method and combined expanded bed hydrogenation reactor

A hydrogenation reactor and hydrogenation reaction technology, which are applied in the fields of hydrotreating process, chemical instruments and methods, and petroleum industry, etc., can solve the problems of inability to achieve clear separation, difficulty in ensuring long-term stable work, and reduced separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

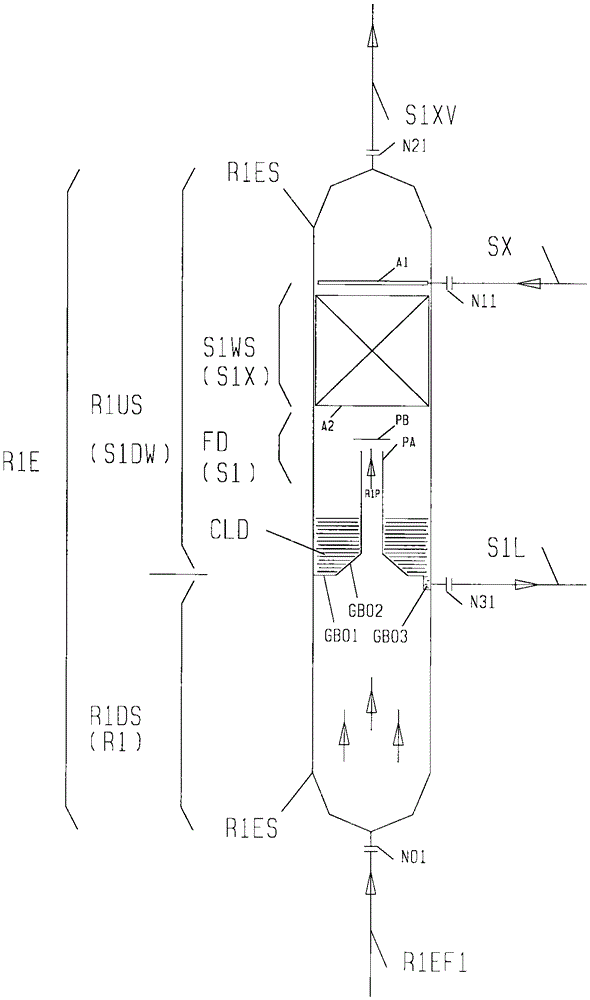

[1263] The first hydrogenation reaction process R1 is a hydrogenation process using a suspended bed for the heavy fraction of medium and low temperature coal tar whose conventional boiling point is higher than 350°C; two suspended bed hydrogenation reactors are used in series; the first suspended bed The hydrogenation reactor is a conventional suspended bed hydrogenation reactor, that is, it does not have the function of product separation and gas phase washing; the second suspension bed hydrogenation reactor is figure 1 The combined suspended bed reactor with the structure shown is equipped with a hot and high-pressure separation gas washing process S1DW, and a flashing step S1 and a washing step S1X.

[1264] The hydrocarbon condensed liquid obtained by cooling the hot high fraction gas S1V is used as washing oil SX by gravity flow.

[1265] The heat exchanger HX100 for cooling the hot high fraction gas S1V to obtain the washing oil SX is arranged on the upper platform of th...

Embodiment 2

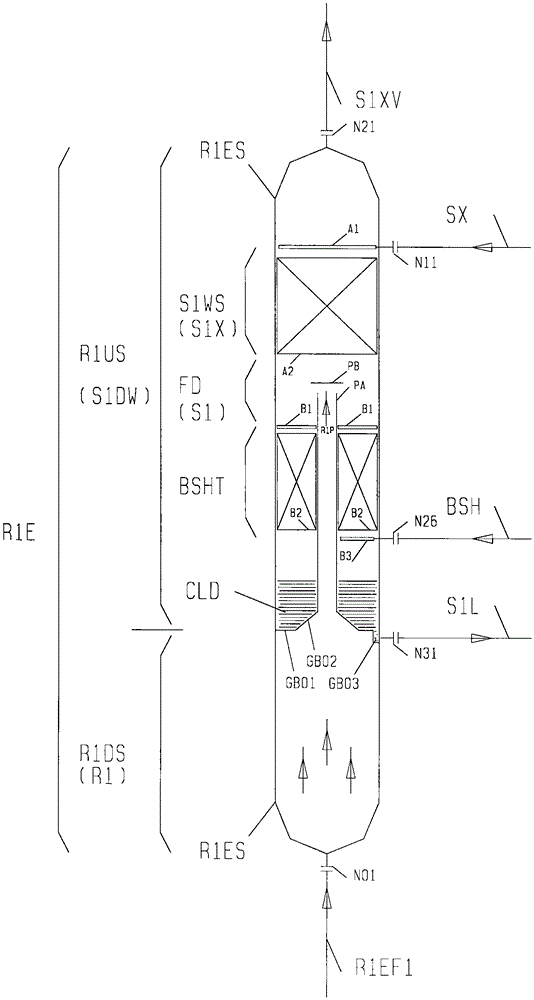

[1267] The first hydrogenation reaction process R1 is a hydrogenation process using a suspended bed for the heavy fraction of medium and low temperature coal tar whose conventional boiling point is higher than 350°C; two suspended bed hydrogenation reactors are used in series; the first suspended bed The hydrogenation reactor is a conventional suspended bed hydrogenation reactor, that is, it does not have the function of product separation and gas phase washing; the second suspension bed hydrogenation reactor is figure 2 The combined suspended bed reactor with the structure shown is equipped with a hot and high-pressure separation gas washing process S1DW, and a flashing step S1 and a washing step S1X.

[1268] The hydrocarbon condensed liquid obtained by cooling the hot high fraction gas S1V is used as washing oil SX by gravity flow.

[1269] The heat exchanger HX100 for cooling the hot high fraction gas S1V to obtain the washing oil SX is arranged on the upper platform of t...

Embodiment 3

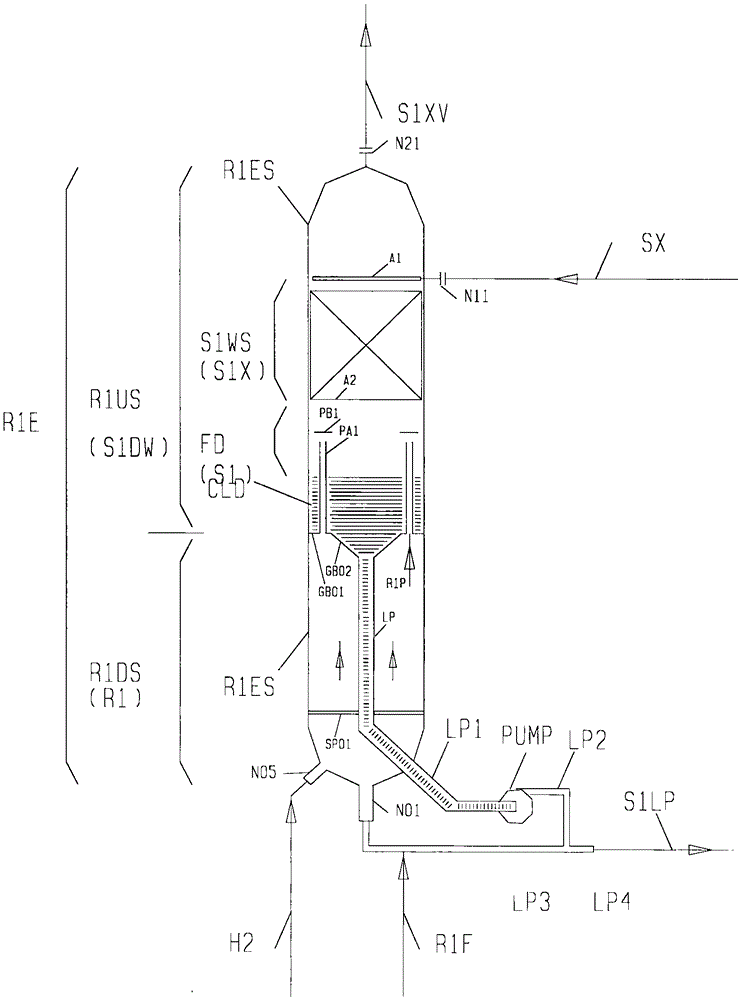

[1271] The first hydrogenation reaction process R1 is a hydrogenation process using an ebullating bed for the heavy fraction of medium and low temperature coal tar whose conventional boiling point is higher than 350°C; two ebullating bed hydrogenation reactors are used in series; the first ebullating bed The hydrogenation reactor is a conventional ebullated bed hydrogenation reactor, that is, it does not have the function of product separation and gas phase washing; the second ebullating bed hydrogenation reactor is image 3 The combined ebullating bed reactor with the structure shown is equipped with a hot and high-pressure separation gas washing process S1DW, a flashing step S1, and a washing step S1X.

[1272] The hydrocarbon condensed liquid obtained by cooling the hot high fraction gas S1V is used as washing oil SX by gravity flow.

[1273] The heat exchanger HX100 for cooling the hot high fraction gas S1V to obtain the washing oil SX is arranged on the upper platform of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com