Load sensing control system, control method and hydraulic system

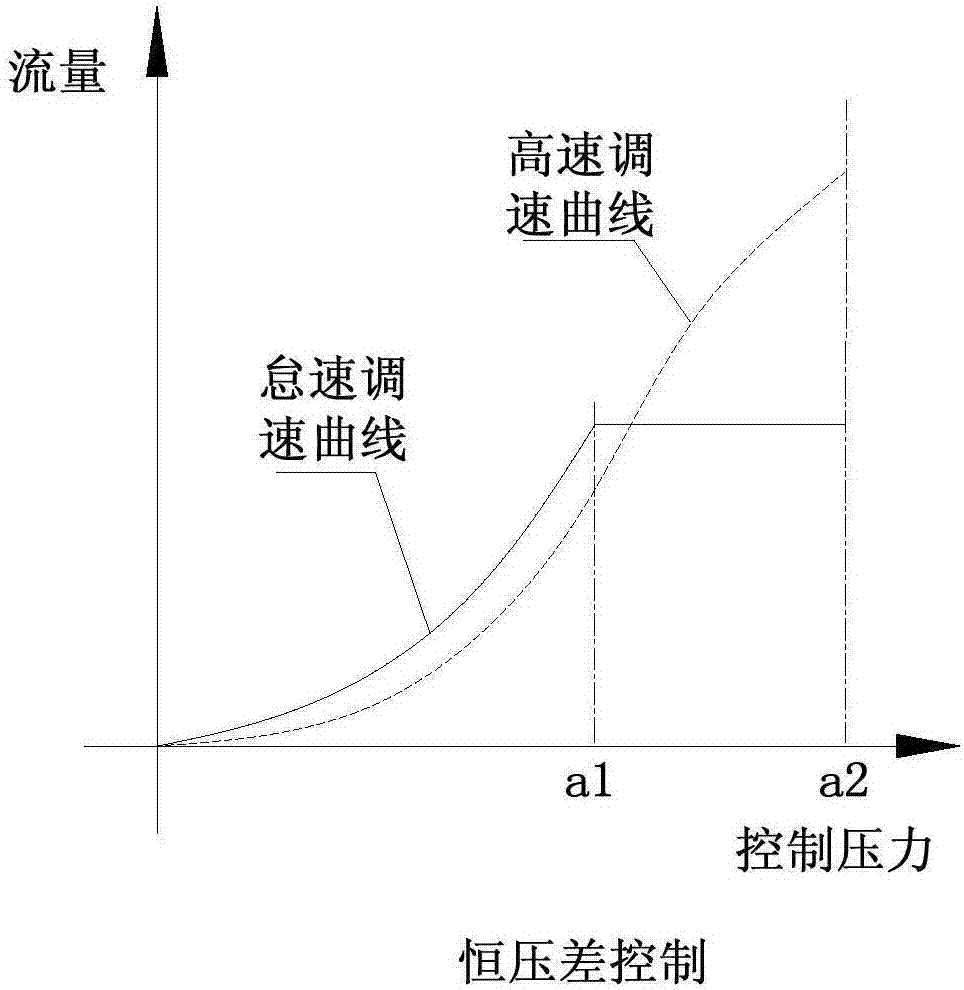

A load-sensitive control and control valve technology, applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., can solve problems such as large empty travel, high pressure difference, and system flow can not go up, so as to eliminate flow saturation phenomenon, Improvement of speed control characteristics and improvement of energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

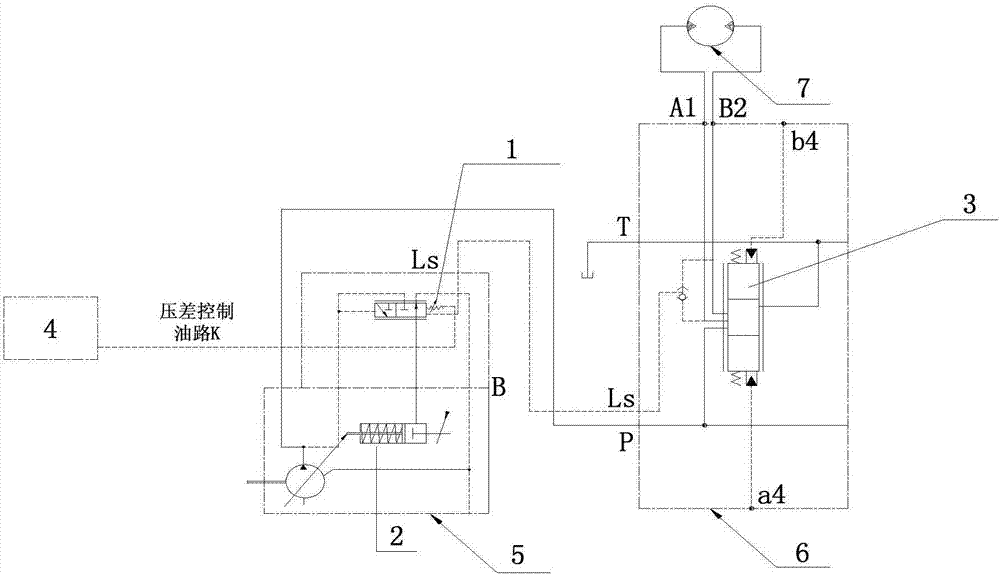

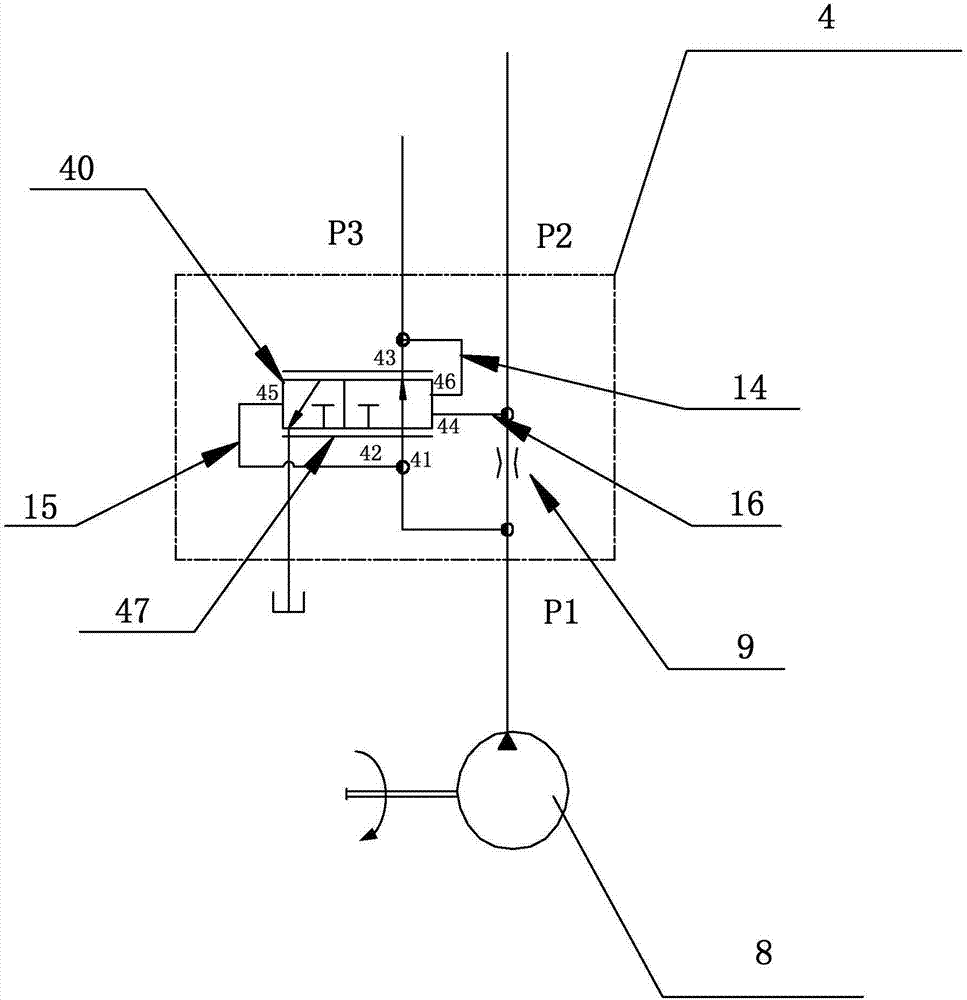

[0033] Combine below Figure 1 to Figure 4 The technical solution provided by the present invention is described in more detail.

[0034] see figure 2 , the embodiment of the present invention provides a load sensing control system, including a variable displacement pump 5 , a load feedback oil circuit Ls and a differential pressure control valve 1 . The differential pressure control valve 1 is connected with the variable variable pump 5 and the load feedback oil circuit Ls, and the differential pressure control valve 1 can make the difference between the outlet pressure of the variable variable pump 5 and the load pressure on the load feedback oil circuit Ls change.

[0035] In this embodiment, the load sensing control system includes a differential pressure control valve 1 , a variable oil pump cylinder 2 , a reversing control valve 3 , a variable pump 5 and a speed matching valve 4 . Taking the winch motor 7 as the load end as an example, the load feedback oil circuit Ls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com