Optical impedance modulation for fuel quantity measurement

A fuel and optical fiber technology, applied in the measurement capacity, measurement device, measurement inclination, etc., can solve the problems of complex installation and protection measurement, and achieve the effect of avoiding the accumulation of pollutants, reducing costs, and maintaining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Various embodiments of systems and methods for measuring a liquid level in a reservoir will now be described in detail for purposes of illustration. At least some of the details disclosed below relate to optional features or aspects, which in some applications may be omitted without departing from the scope of the appended claims.

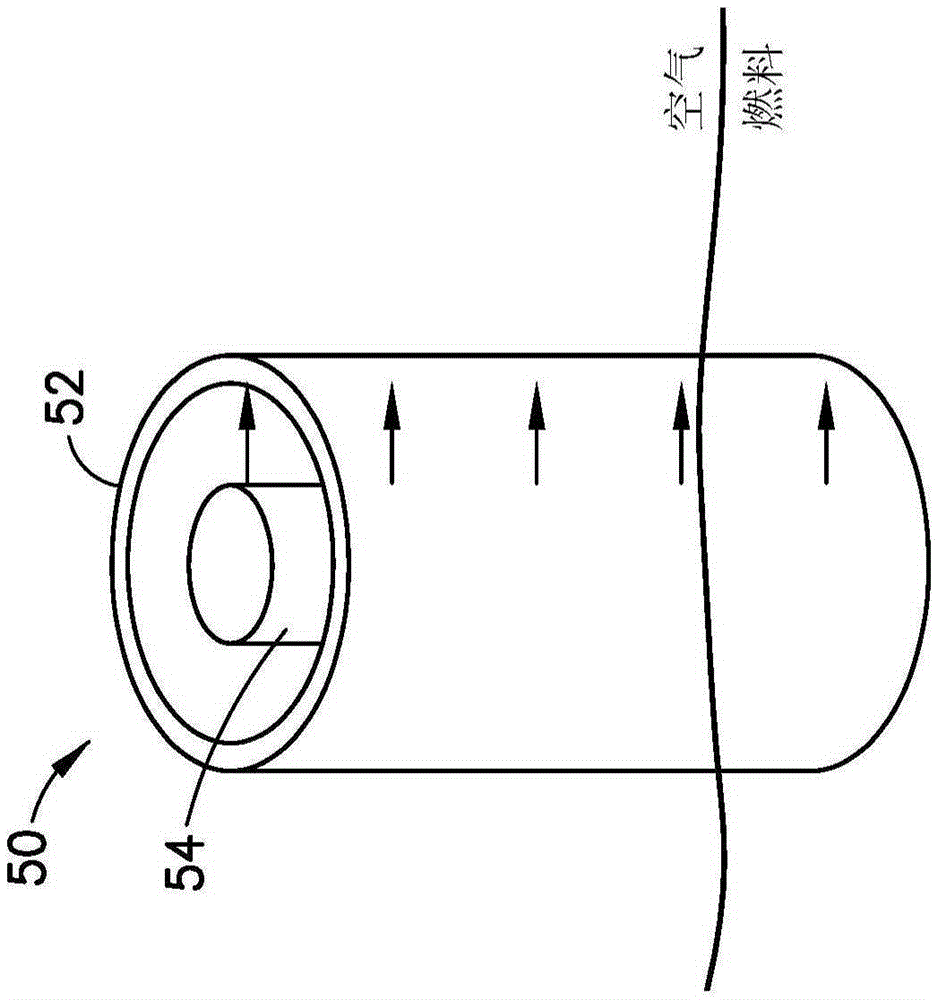

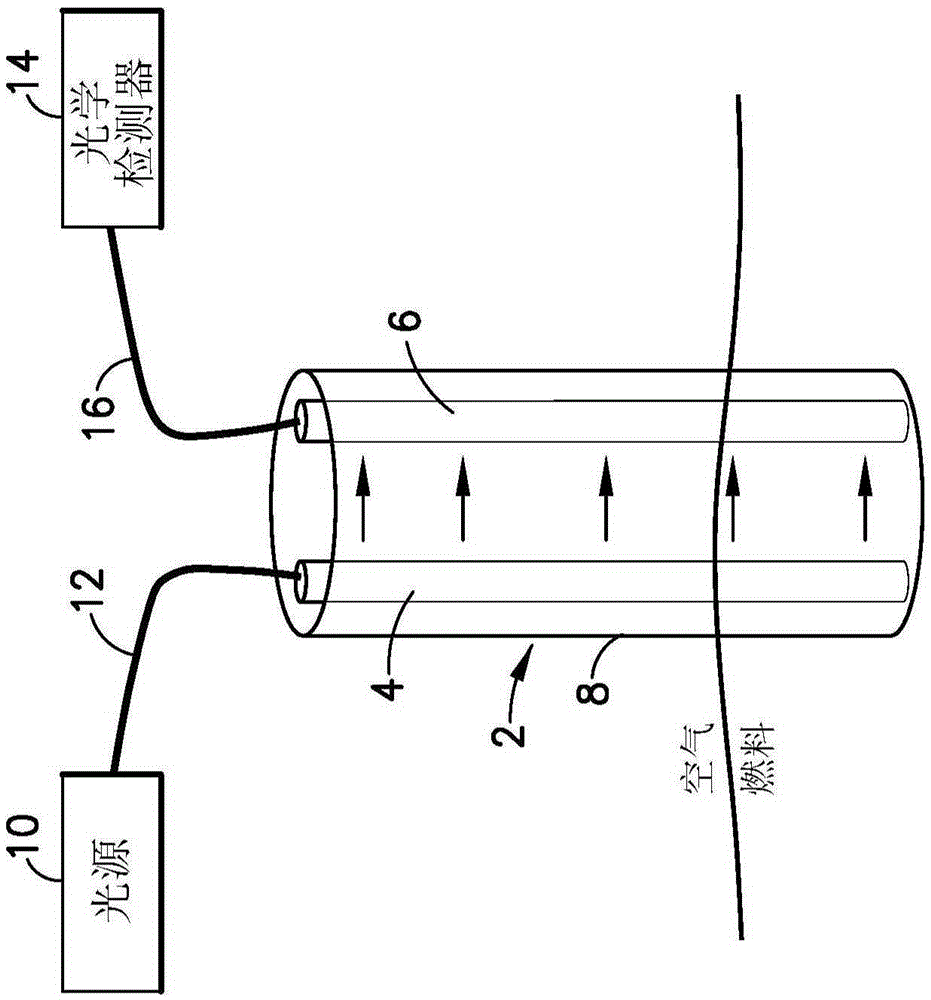

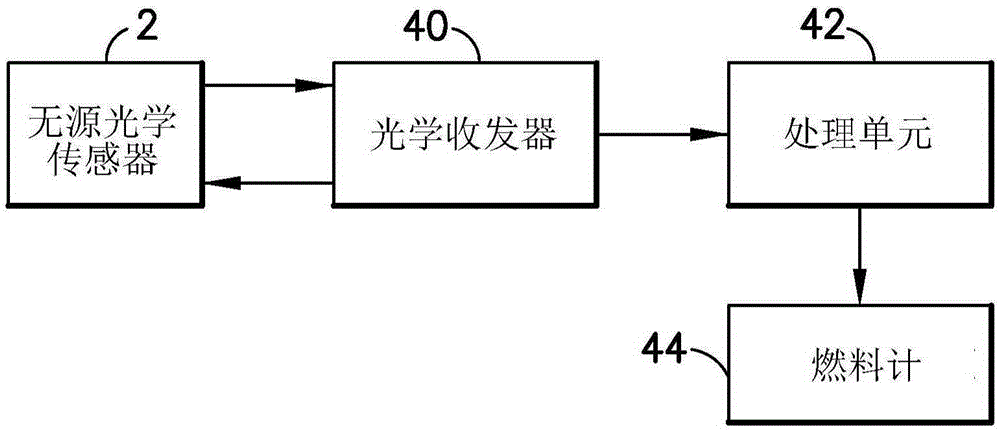

[0029] figure 1 A liquid level sensor 50 is shown comprising an aluminum inner tube 54 and an aluminum outer tube 52 surrounding and concentric with the aluminum inner tube 54 . A generally horizontal non-linear line across fluid level sensor 50 represents the fuel level, ie, the interface between fuel and air. Some fuel takes up the space between the aluminum tubes. The overall capacitance of the fluid level sensor 50 varies with fuel level in a well known manner (air and fuel have different dielectric constants). The arrows represent the charge flow from the aluminum inner tube 54 towards the aluminum outer tube 52 under the influence o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com