Transparent medium film refractive index and thickness on-line measuring method

A transparent medium and measurement method technology, applied in the direction of measuring device, phase influence characteristic measurement, instrument, etc., can solve problems such as disconnection, inconvenient and simple control, difficult to accurately determine the optical constant and thickness of the film layer, and achieve accurate results and analysis convergence fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

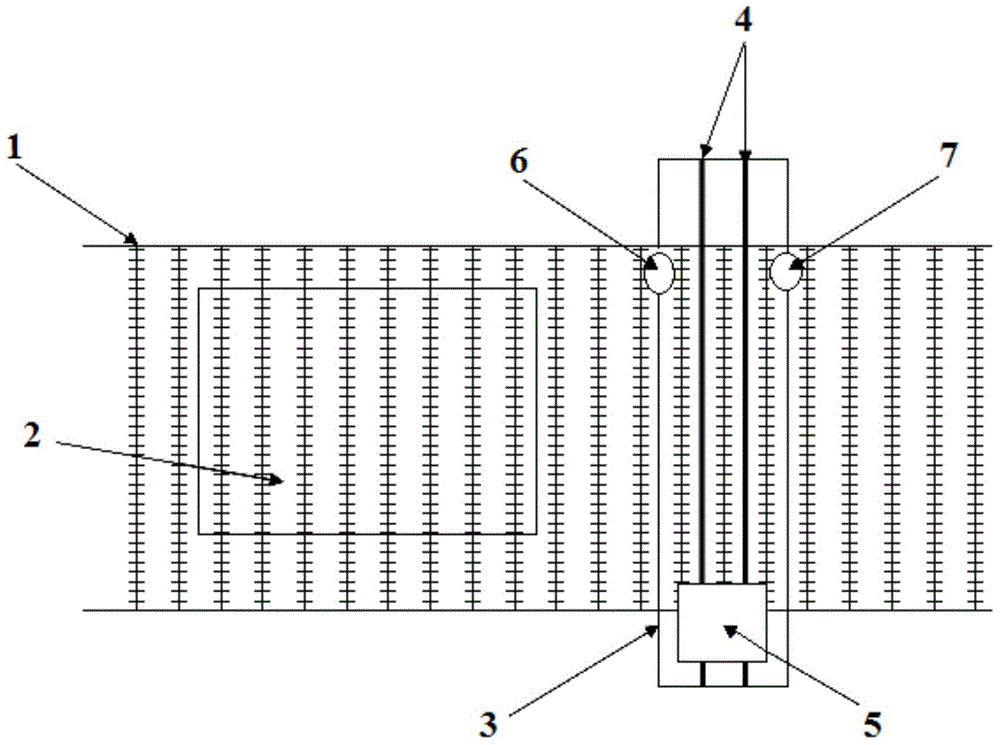

[0037] see figure 1 , an on-line spectrum measuring device, comprising a bracket 3, a guide rail 4 is arranged on the bracket 3, a measuring probe 5 is arranged on the guide rail 4, a first position sensor 6 is arranged on the bracket 3 on one side of the guide rail 4, and a first position sensor 6 is arranged on the bracket on the other side 3 is provided with a second position sensor 7, when the first position sensor 6 and the second position sensor 6 simultaneously detect the measured coating sample 2, the measuring probe 5 moves step by step along the guide rail 4 above the measured coating sample 2 The scanning test is used to test the reflectance spectrum of each point of the coating sample 2 to be tested. A plurality of conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com