Copper-doped yttrium aluminate crystal for thermoluminescence and photoluminescence and preparation method thereof

A technology of photoluminescence and thermoluminescence, used in chemical instruments and methods, crystal growth, single crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

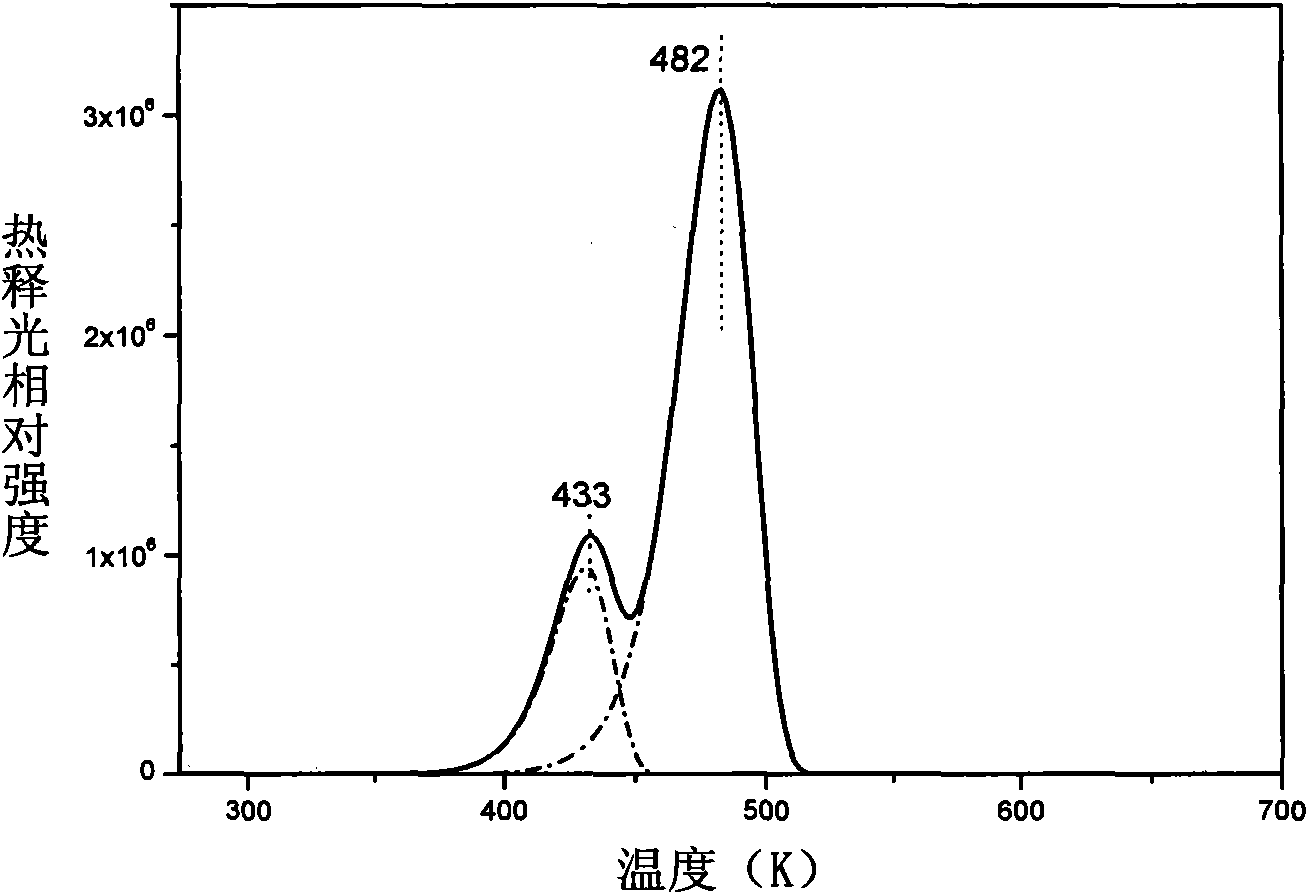

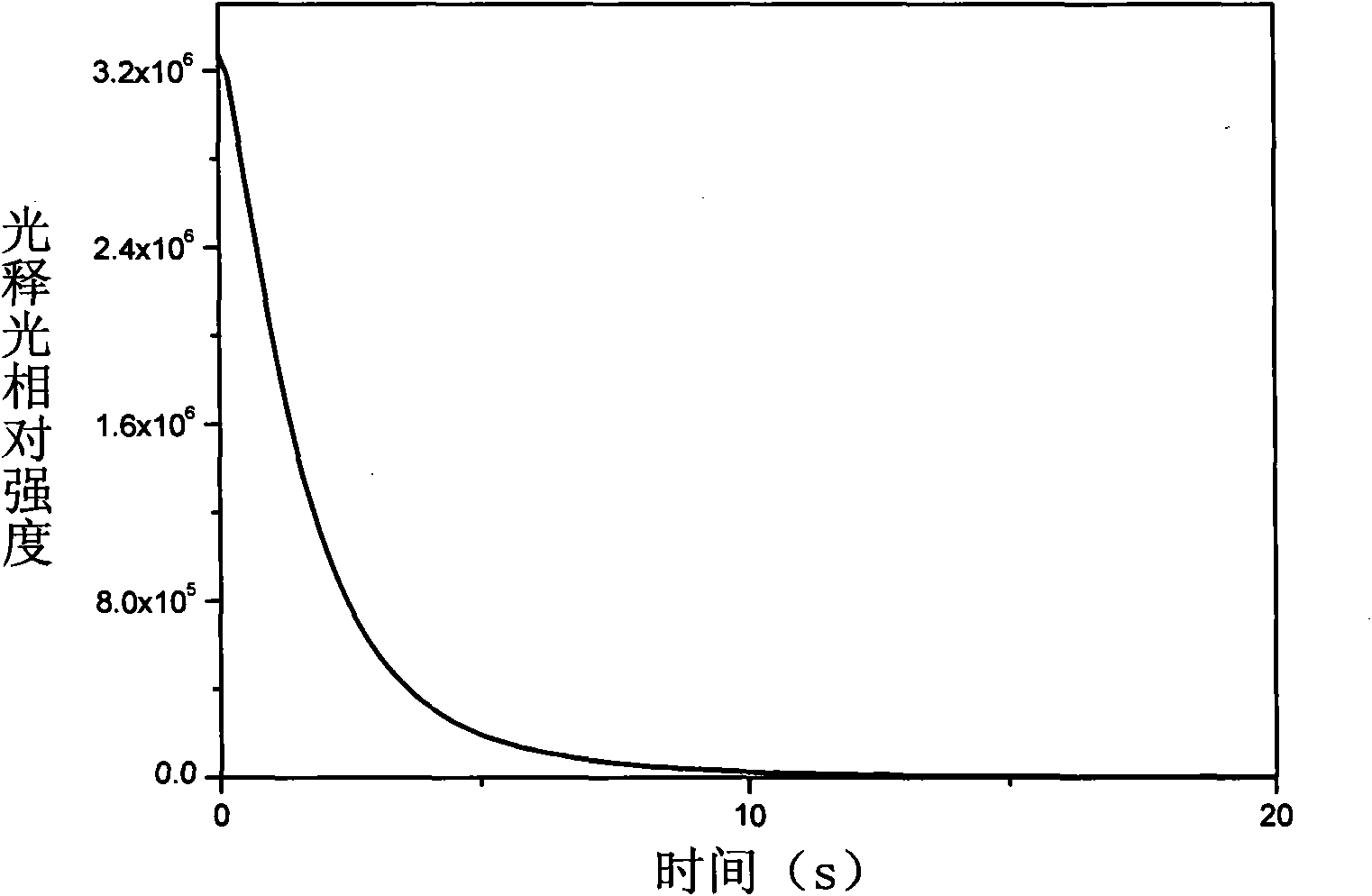

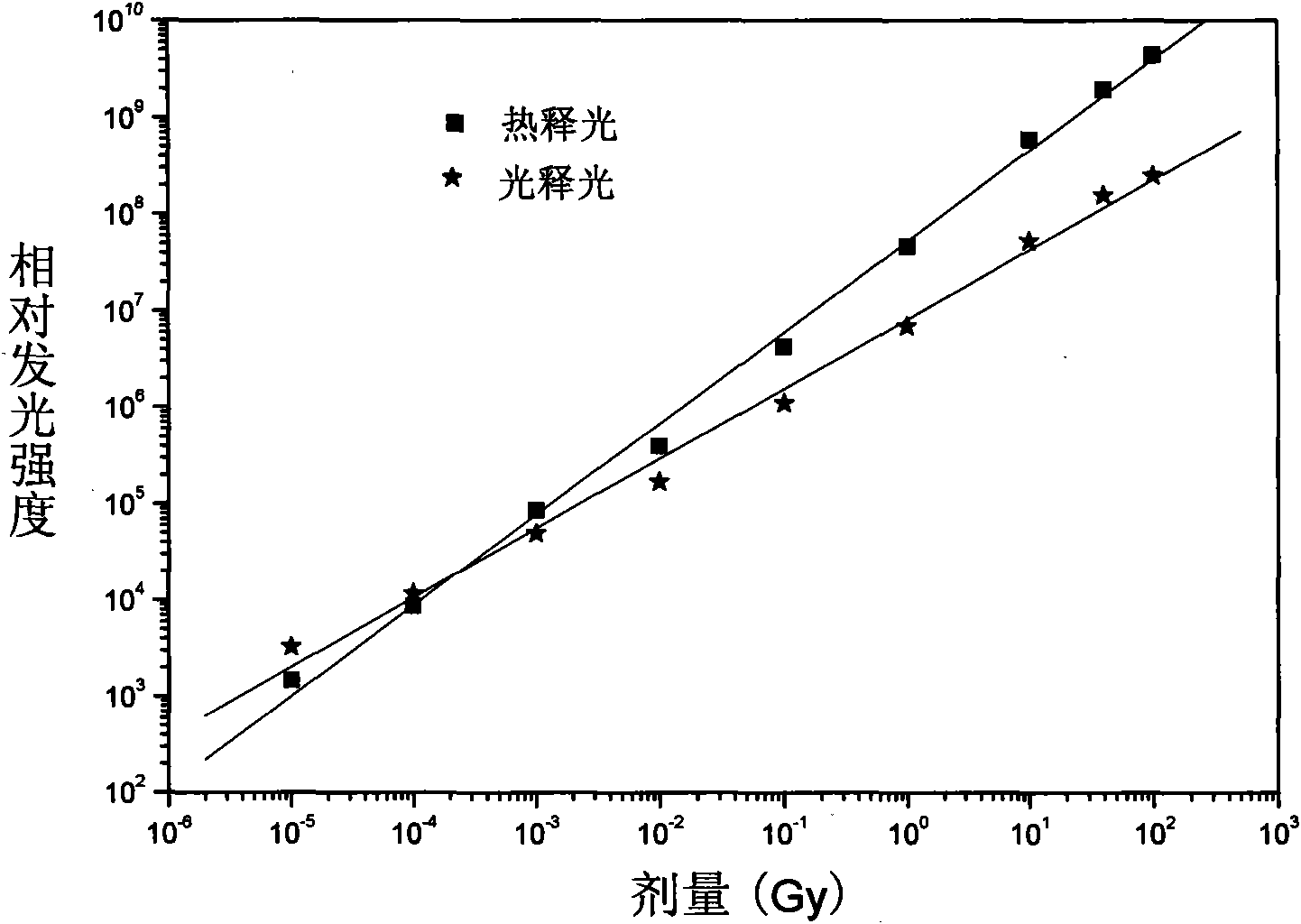

Embodiment 1

[0024] Firstly, each high-purity oxide powder is properly pre-dried in the air to remove adsorbed water, and the burning temperature is 1000°C. Then Al 2 o 3 (5N), Y 2 o 3 (5N) and CuO(3N) raw materials are weighed and compounded according to the molar ratio equal to 1:0.995:0.01. After mixing evenly, press it into a block on a hydraulic press, put it in an iridium crucible, and use the pulling method to grow the crystal. The seed crystal is a pure YAP single crystal rod in the direction (longest axis), and the crystal is grown in a high-purity Ar atmosphere. conduct. The pulling speed of the crystal is 1.5mm / h, the rotation speed is 18rpm, and the growth of the convex interface of the crystal is controlled. All crystal growth is carried out through furnace loading→vacuumizing→argon filling→heating material→baking seed→planting→necking→ Shouldering→equal diameter growth→lifting and cooling. The whole growth cycle is about 5 days. The thermoluminescent and optical lumine...

Embodiment 2

[0028] Firstly, each high-purity oxide powder is properly pre-dried in the air to remove adsorbed water, and the burning temperature is 1000°C. Then Al 2 o 3 (5N), Y 2 o 3(5N) and CuO(3N) raw materials are weighed and compounded according to the molar ratio equal to 1:0.997:0.006. After mixing evenly, press it into a block on a hydraulic press, put it in an iridium crucible, and use the pulling method to grow the crystal. The seed crystal is a pure YAP single crystal rod in the direction (longest axis), and the crystal is grown in a high-purity Ar atmosphere. conduct. The pulling speed was 1.2 mm / h, and the rotation speed was 15 rpm.

Embodiment 3

[0030] Firstly, each high-purity oxide powder is properly pre-dried in the air to remove adsorbed water, and the burning temperature is 1000°C. Then Al 2 o 3 (5N), Y 2 o 3 (5N) and CuO(3N) raw materials are weighed and compounded according to the molar ratio equal to 1:0.996:0.008. After mixing evenly, press it into a block on a hydraulic press, put it in an iridium crucible, and use the pulling method to grow the crystal. The seed crystal is a pure YAP single crystal rod in the direction (longest axis), and the crystal is grown in a high-purity Ar atmosphere. conduct. The pulling speed was 2 mm / h, and the rotation speed was 18 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com