Retractable automatic-spin defect detecting and positioning device for storage tank walls

A defect detection and positioning device technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems that the detection speed is only 25mm/s, the data surface condition is greatly affected, and the defect positioning cannot be realized, so as to reduce the detection cost , Improve detection safety, improve detection accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

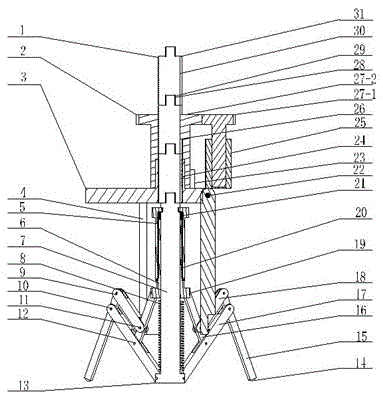

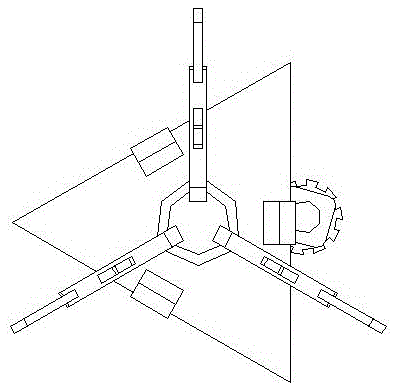

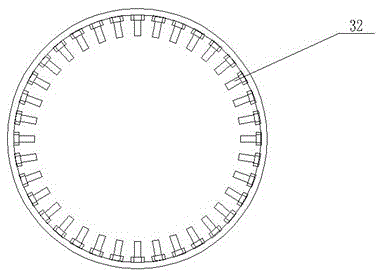

[0021] Attached below figure 1 , 2 , 3, 4, 5 further illustrate the device of the present invention.

[0022] In the ultrasonic testing process of tank wall defects, firstly, the triangular platform 3 is erected on the tank mouth through the fixed hinge bracket 4 with three cylindrical pins 22 forming an angle of 120 degrees, and the driving motor 25, the motor gear 27-1, and the screw rotating box are started. The gear 27-2 rotates, and the screw rotating box gear drives the screw rotating box 2 to rotate. The screw rotating box 2 cooperates with the screw 1 through the keyway, and the screw 1 is screwed into the sleeve 24 of the triangular platform. After screw rod 1 is partly unscrewed from triangular platform 3, drive motor 25 is turned off, screw rod 1 stops rotating, and long axis 7 equipped with radial downward pressure system, telescopic linkage system, ultrasonic array probe and screw rod 1 are rotated into an integral screw rod. The major axis 7 is positioned below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com