Micro-torsion mirror driven by one-side unequal height comb teeth

A technology of micro-torsional mirrors and comb teeth is applied in the field of high-comb electrostatically driven micro-torsional mirrors and their preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

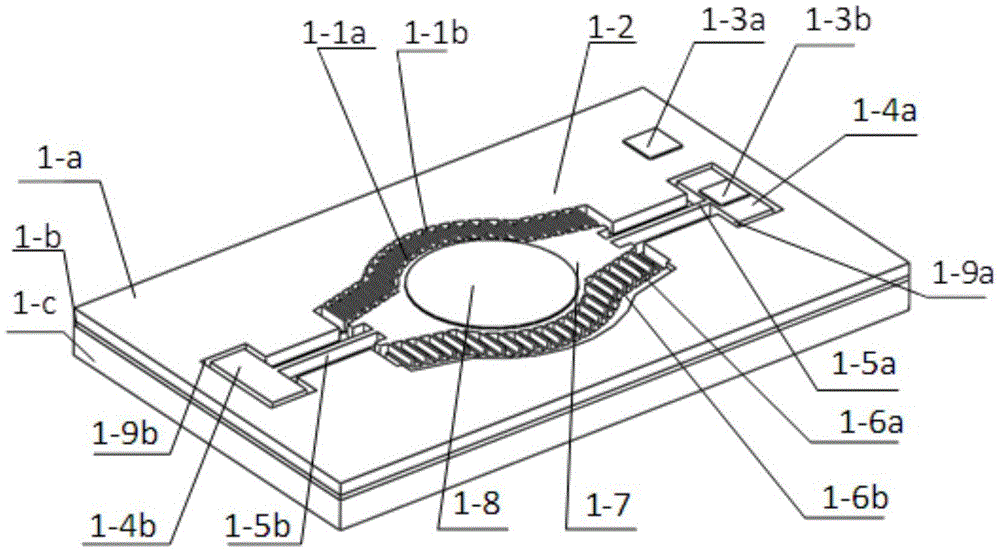

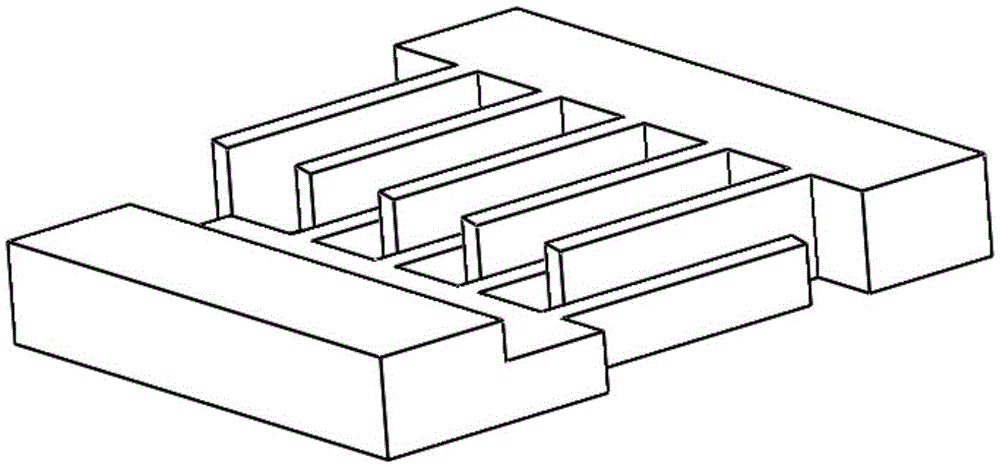

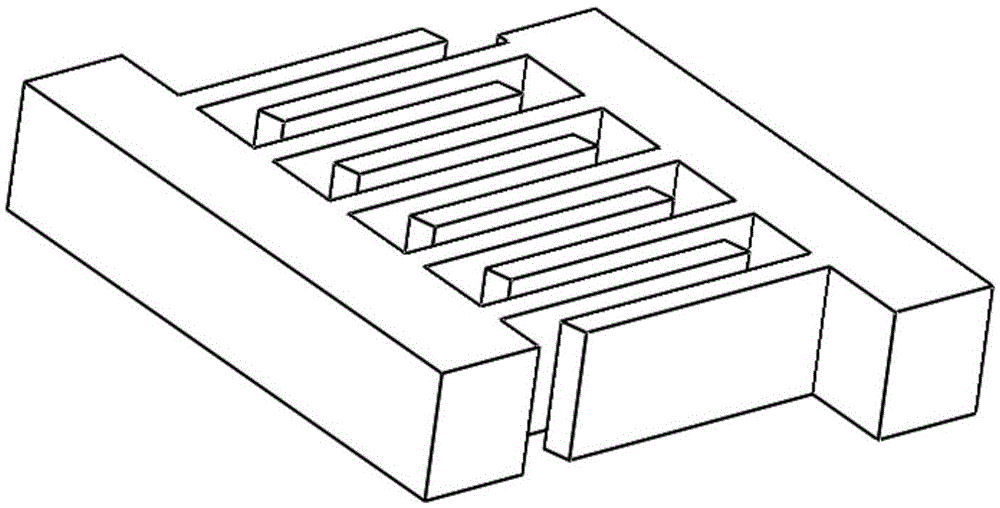

[0023] The present invention proposes a micro-torsion mirror driven by comb teeth with unequal heights on one side. The micro-torsion mirror is made of SOI silicon wafer, and mainly consists of a device layer 1-a, a buried oxide layer 1-b, and a base layer 1-c. Composed of three layers, its structure is as follows figure 1 shown. The base layer 1-c is used to make the back cavity structure to provide movable space for the movable mirror; the buried oxide layer 1-b is used for the electrical isolation of the device layer 1-a and the base layer 1-c; the device layer 1-a is used for The structure of each part of the micro-torsion mirror, including the movable mirror structure 1-7 and the reflective layer 1-8 on it, the first torsion support beam 1-5a, 1-5b and its anchor point 1-4a, 1 -4b, the first comb structure 1-1 and the second comb structure 1-6, comb anchor points and pads 1-3a, 1-3b, etc.; wherein, the first comb structure 1-1 and the second Comb tooth structures 1-6 ar...

Embodiment 2

[0033] refer to Figure 4 , a two-dimensional micro-torsion mirror driven by combs with unequal heights on one side based on SOI, which is proposed in this embodiment, consists of three layers: a device layer 1-a, a buried oxide layer 1-b in the middle, and a base layer 1-c composition. The base layer 1-c is used to make a back cavity structure, which provides movable space for the movable mirror structure 1-7 and the movable frame 6-4; the buried oxide layer 1-b is used for the electrical connection between the device layer 1-a and the base layer 1-c. isolation. The device layer 1-a is used to make the movable mirror structure 1-7 and the reflective layer 1-8 thereon, the first torsion support beams 1-5a and 1-5b of the movable mirror structure 1-7, and the movable mirror structure The first comb tooth structure, the movable frame 6-4 supporting the first torsion support beam of the movable mirror structure, the second torsion support beams 6-8a and 6-8b of the movable fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com