Energy storage device with multiple cores stacked inside

A device and energy storage technology, which is applied in the field of energy storage manufacturing, can solve problems such as the difficulty in manufacturing high-capacity and high-power energy storage devices, and achieve the effects of making full use of installation space, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

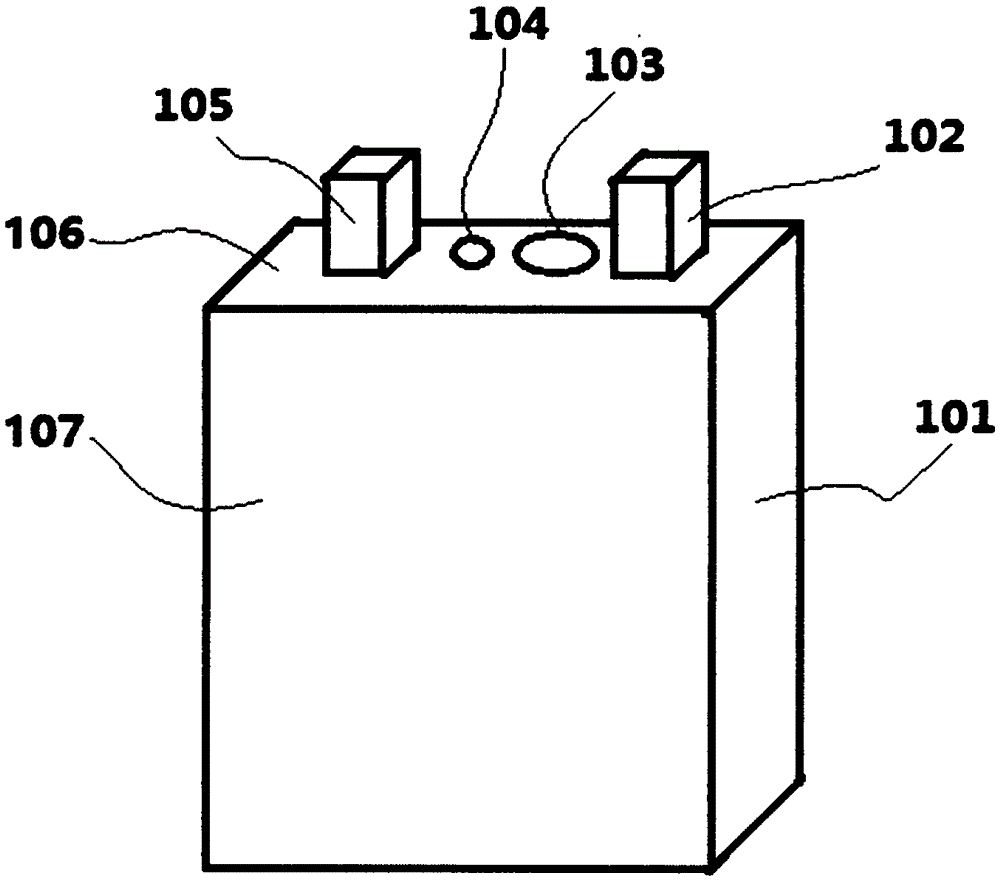

[0021] In order to illustrate the present invention, the present embodiment makes 220Ah cuboid lithium ion battery, and appearance is as follows figure 1 shown. The positive electrode material of lithium ion energy storage device usually adopts LiFePO 4 , LiNiCoMnO 2 , LiNiCoAlO 2 , LiMn 2 o 4 , LiCoO2, or a mixture of two of them, and the negative electrode material is C, Li 4 T 15 o 12 , Si or its compounds, Sn or its compounds, the electrolyte uses 1.2MLiPF 6 +EC+EMC, diaphragm adopts PE film, PP film, PP / PE film, coated with SiO 2 or Ai 2 o 3 PE composite film.

[0022] Prefabricate the energy storage device cover plate 106 with the positive and negative poles on the same top surface, use an aluminum plate with a thickness of 1mm, cut it into 58×135mm, and open it according to the designed position The explosion-proof disk installation hole, The liquid injection hole 104 and the hole for installing the pole; the positive pole 102 and the negative pole 105 ar...

Embodiment 2

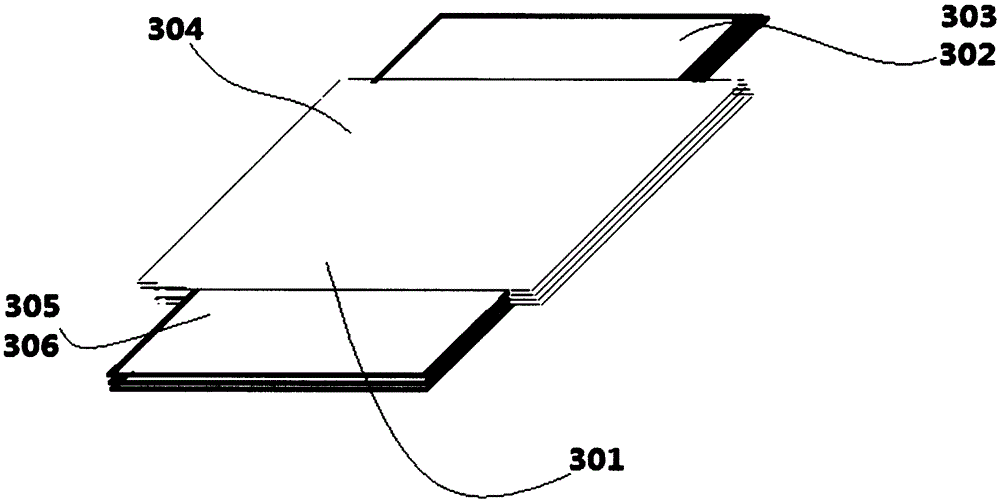

[0027] Make a 220Ah cuboid lithium-ion battery, which looks like figure 1shown. Except that the small core package adopts a winding cuboid structure, the materials, method and size of the battery are the same as in Example 1. The coating width of the positive and negative pole pieces and the wide band of the smooth edge are the same as in Example 1; the positive and negative pole pieces of the whole roll are respectively cut into 305 rolls of positive pole pieces and 302 rolls of negative pole pieces with a width of 124mm and 125mm, and the whole roll of diaphragm is cut into 124mm 304 rolls of wide diaphragms; use a winding machine to roll into a small core package with a thickness of 9mm, a length of 134mm, and a width of 56mm, and use ultrasonic welding, laser welding, or riveting methods to connect the positive and negative electrodes of the small core package respectively. As a whole, make a small core pack 401 with a winding rectangular parallelepiped structure of the p...

Embodiment 3

[0029] To make a 22000F supercapacitor, except for the positive and negative materials, the same 1500m 2 The active carbon of / g, the negative current collector are aluminum foil, the conductive connecting sheet 502 is changed into aluminum material and electrolytic solution adopts 1.2MTEABF4+PC, other and embodiment 1 make 220Ah rectangular parallelepiped lithium-ion battery method and size are identical. The size of 22000F supercapacitor 101 is the same as that of the battery 101 in Embodiment 1, and its shape is as follows figure 1 shown. The capacitor is charged to 2.7V with 1000A, and discharged to 1.35V with 1000A constant current. The measured rated capacity is 22000F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com