Automatic inspection device for power device

An automatic inspection and power equipment technology, applied in the direction of overhead lines/cable equipment, signal transmission systems, instruments, etc., can solve the problem of heavy physical exertion of power workers, inability to conduct comprehensive inspections, and limited items of manual inspections, etc. problems, to achieve the effect of strong adaptability, diverse functions, and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

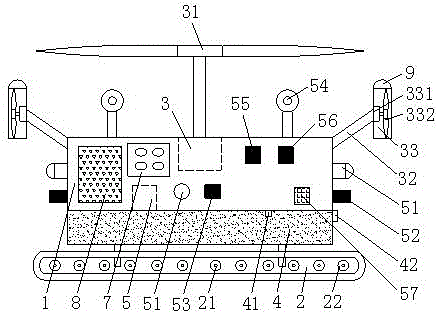

[0018] See Figure 1-2 , The present invention provides a technical solution: an automatic inspection device for power equipment, including a body 1 and a remote monitoring device 6, the body 1 is driven by a driving device, the driving device is a crawler 2, and the middle of the crawler 2 passes through a support rod and the body 1. Fixed connection. The middle and both ends of the crawler belt 2 are respectively provided with a driving wheel 21 and a steering wheel 22. The steering wheel 22 can adjust the walking direction of the body 1. The driving motors of the driving wheel 21 and the steering wheel 22 are electrically connected to the central processor 5. The body 1 is driven by the crawler belt 2, which is convenient for the body 1 to work on the ground or in the laying tank. The body 1 is powered by the power supply system installed in it. The power supply system includes a first battery 4 installed inside the body 1 and the inside and outside of the first battery 4 A ...

Embodiment 2

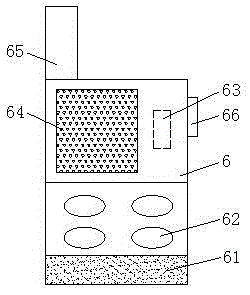

[0020] See Figure 1-2 The present invention provides another technical solution: an automatic inspection device for power equipment, including a body 1 and a remote monitoring device 6. The body 1 is driven by a driving device, and the driving device is a driving motor 3 installed on the upper part of the body 1. The driving motor The upper end of the rotating shaft of 3 is connected with a driving propeller 31. Both ends of the body 1 are connected to a bogie 33 through connecting rods 32 inclined at 45 degrees. A steering motor 331 is installed at the end of the bogie 33. There is a steering propeller 332. The steering motor 331 cooperates with the steering propeller 332 to adjust the flight direction of the body 1. The upper end of the bogie 33 is provided with a first wireless transceiver 9 which is connected to the signal mounted on the top of the remote monitoring device 6. The second wireless transceiver 65, the drive motor 3 and the steering motor 331 are electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com