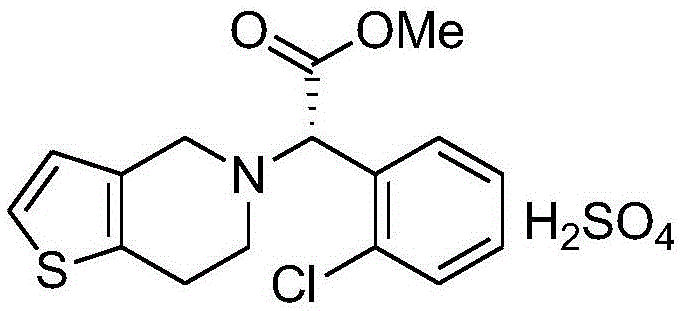

Clopidogrel hydrogen sulfate solid preparation and preparation method thereof

A technology of clopidogrel bisulfate solid and clopidogrel bisulfate, which is applied in the fields of pill delivery, pharmaceutical formula, medical preparations of non-active ingredients, etc., and can solve problems such as too much, difficult to prepare granules, and affecting the dissolution of preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

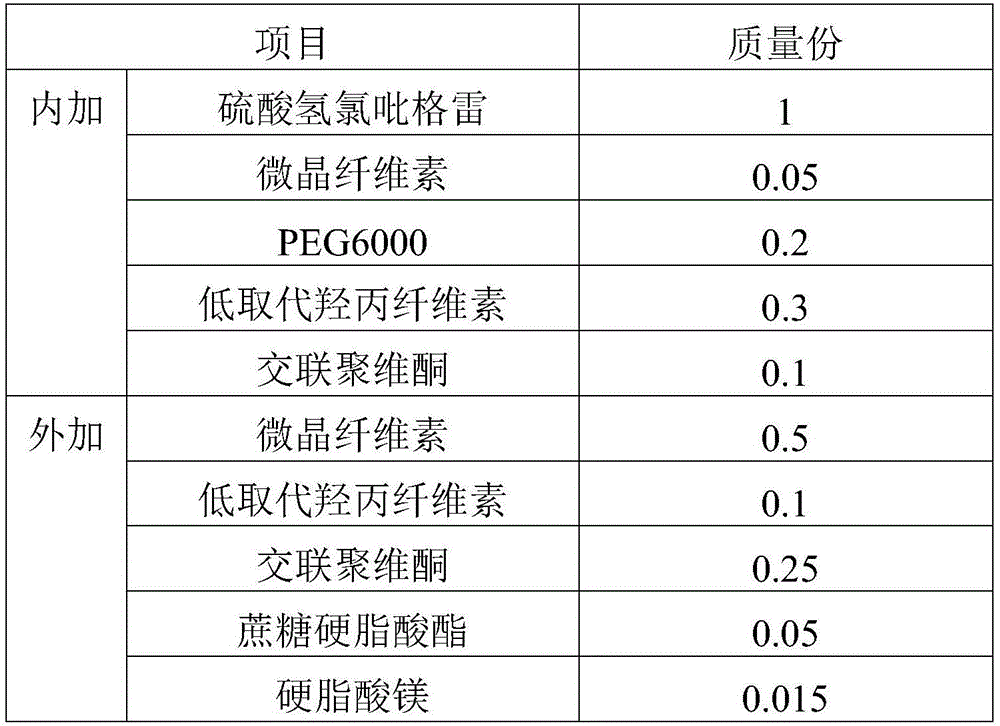

Embodiment 1

[0067] prescription:

[0068]

[0069]

[0070] Preparation steps:

[0071] 1) Mix the prescribed amount of clopidogrel bisulfate (D90=67 μm) with the internally added excipients for 20-30 minutes to obtain the internally mixed powder;

[0072] 2) Add the internal mixed powder obtained in step 1) into a fluidized bed granulator, and granulate at 50-60°C for 10-30 minutes to obtain internal phase granules (angle of repose 37°). The obtained granules are uniform and almost free of fine powder;

[0073] 3) Mix the introverted granules obtained in step 2) with the prescribed amount of external excipients for 10 to 20 minutes to obtain the total mixed granules;

[0074] 4) Compressing the blended granules obtained in step 3) into tablets to prepare a solid preparation of clopidogrel hydrogen sulfate (75 mg specification).

[0075] No sticking phenomenon occurred in the tableting process, and the obtained clopidogrel bisulfate solid preparation had a smooth surface.

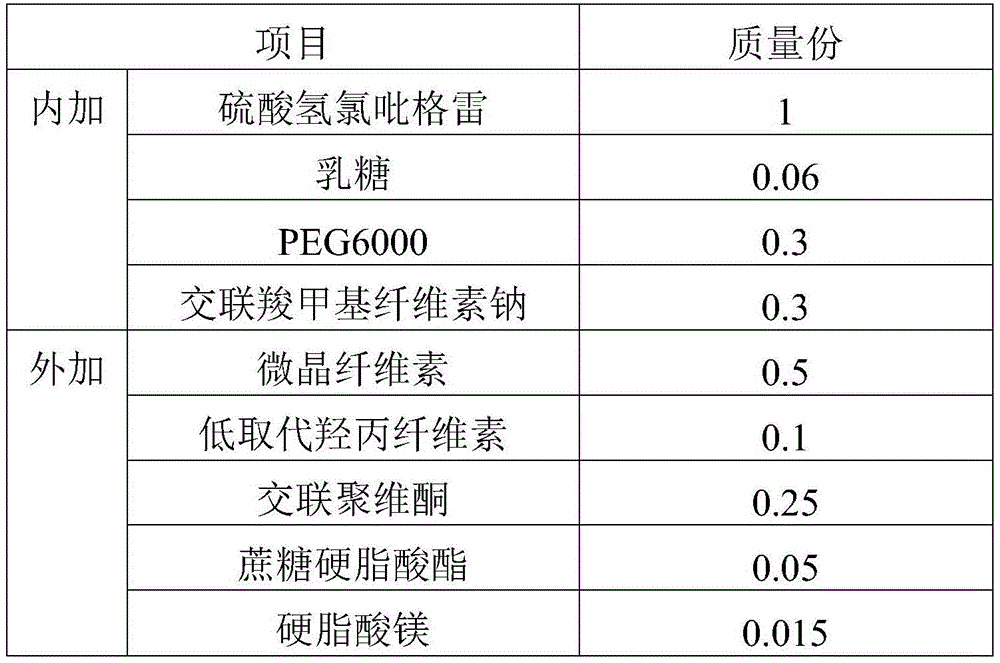

Embodiment 2

[0077] prescription:

[0078]

[0079] Preparation steps:

[0080] 1) Mix the prescribed amount of clopidogrel bisulfate (D90=60 μm) with the internally added excipients for 20-30 minutes to obtain the internally mixed powder;

[0081] 2) Add the internal mixed powder obtained in step 1) into a fluidized bed granulator, and granulate at 50-60°C for 10-30 minutes to obtain internal phase granules (angle of repose 38°). The obtained granules are uniform and almost free of fine powder;

[0082] 3) Mix the introverted granules obtained in step 2) with the prescribed amount of external excipients for 10 to 20 minutes to obtain the total mixed granules;

[0083] 4) Compressing the blended granules obtained in step 3) into tablets to prepare a solid preparation of clopidogrel hydrogen sulfate (75 mg specification).

[0084] No sticking phenomenon occurred in the tableting process, and the obtained clopidogrel bisulfate solid preparation had a smooth surface.

Embodiment 3

[0086] prescription:

[0087]

[0088] Preparation steps:

[0089] 1) Mix the prescribed amount of clopidogrel hydrogen sulfate (D90=73 μm) with the internally added excipients for 20-30 minutes to obtain the internally mixed powder;

[0090] 2) Add the internal mixed powder obtained in step 1) into a fluidized bed granulator, and granulate at 50-60°C for 10-30 minutes to obtain internal phase granules (angle of repose 38°). The obtained granules are uniform and almost free of fine powder;

[0091] 3) Mix the introverted granules obtained in step 2) with the prescribed amount of external excipients for 10 to 20 minutes to obtain the total mixed granules;

[0092] 4) Compressing the blended granules obtained in step 3) into tablets to prepare a solid preparation of clopidogrel hydrogen sulfate (75 mg specification).

[0093] No sticking phenomenon occurred in the tableting process, and the obtained clopidogrel bisulfate solid preparation had a smooth surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| D90 | aaaaa | aaaaa |

| D90 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com