Intelligent line welding method

An intelligent, welding seam position technology, applied in the field of welding seam, can solve the problems of lagging adjustment mode, heavier load, and inability to realize the import function of product CAD graphics, so as to achieve the effect of reducing work intensity and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

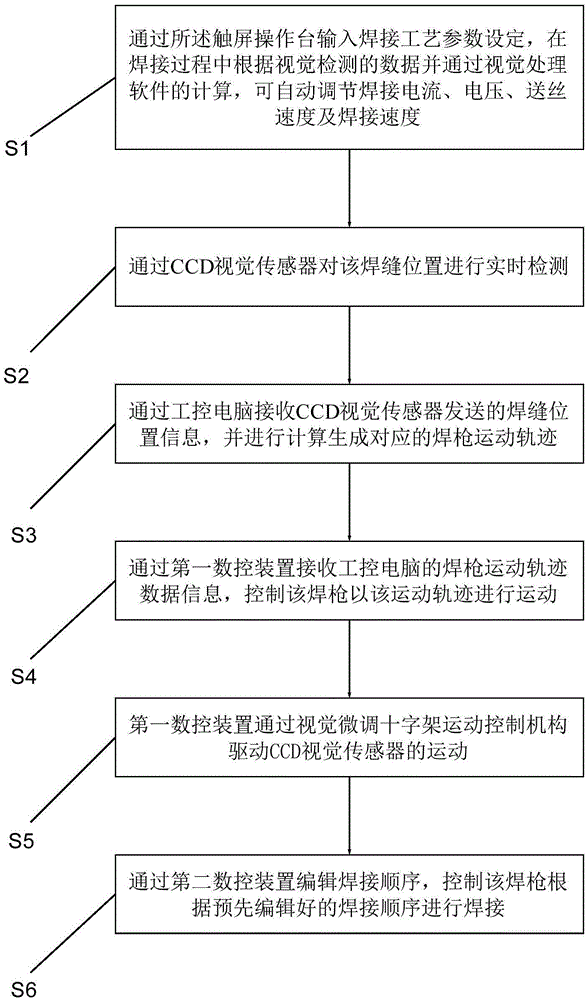

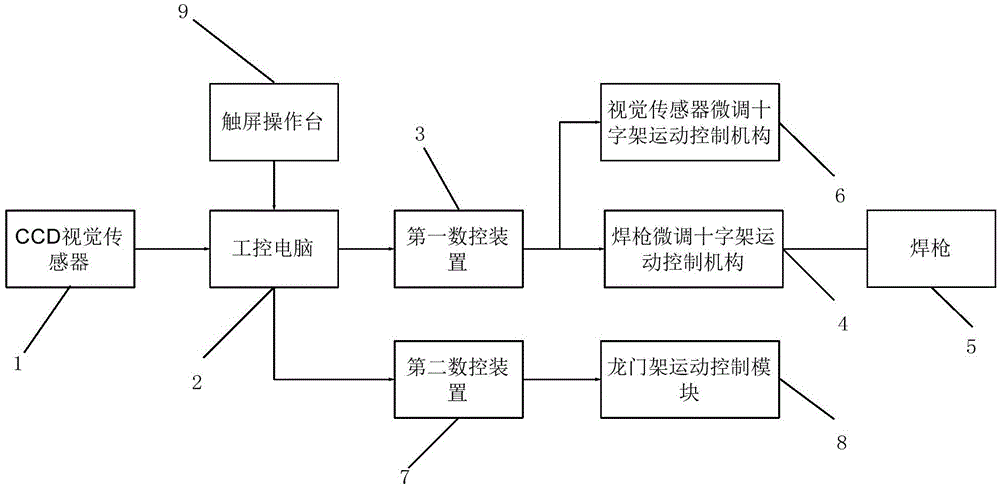

[0041] see figure 2 , which is a flow chart of the steps of the intelligent seam welding method of the present invention. The invention provides a smart seam welding method, which comprises the following steps:

[0042] S1: Input the welding process parameter setting through the touch screen console, and automatically adjust the welding current, voltage, wire feeding speed and welding speed according to the data of the visual inspection and the calculation of the visual processing software during the welding process.

[0043] S2: Real-time detection of the welding seam position through the CCD vision sensor.

[0044] S3: Receive the welding seam position information sent by the CCD vision sensor through the industrial control computer, and calculate and generate the corresponding welding torch movement trajectory.

[0045] S4: receiving the welding torch movement trajectory data information from the industrial computer through the first numerical control device, and control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com