Emergent shutdown method for hydrogenation device in production of hydrogen peroxide

An emergency shutdown, hydrogen peroxide technology, applied in chemical instruments and methods, peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve hydrogenation liquid flash explosion, Catalyst agglomeration, danger and other problems to achieve the effect of preventing excessive hydrogenation, protecting the catalyst and preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

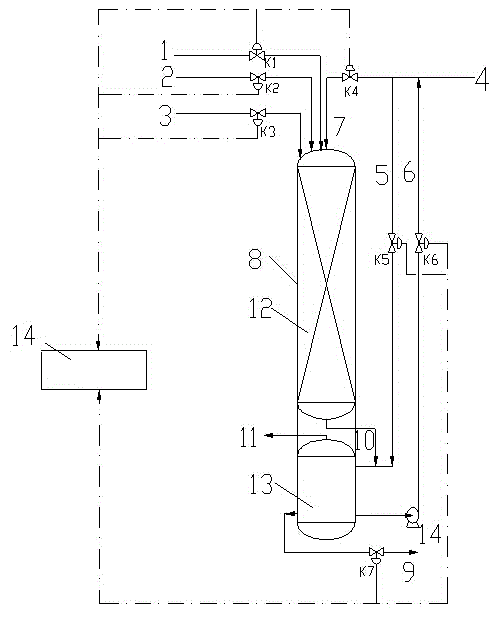

[0032] The emergency shutdown system using this hydrogenation system, hydrogen 1 is 105Nm 3 / h, working fluid 4 is 3.12m 3 / h, circulating working fluid 6 is 0.71m 3 / h, the total working fluid 7 is 3.83m 3 / h. When the emergency hydrogenation shutdown system is turned on, first start the emergency shutdown system 14 of the hydrogenation system, and instantly close the hydrogen feed valve K1; open the valve K6 of the working fluid circulation pipeline, and close the valve K7 that discharges the working fluid to the next process. The working fluid is circulated at 100%; when the outlet temperature of the hydrogenation tower drops to 45°C, open the bypass valve K5 of the working fluid, close the valve K4 where the working fluid enters the hydrogenation tower; open the valve K2 of the low-temperature aromatics feed line to the hydrogenation tower Introduce 48℃ low-temperature aromatic hydrocarbons, wash the catalyst bed for 3 minutes, and then introduce 40℃ low-temperature aromatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com