Patents

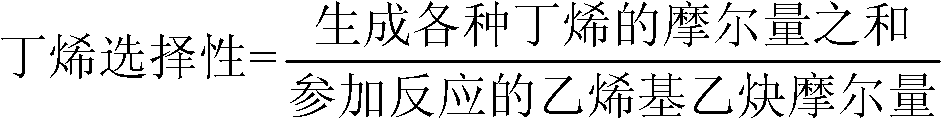

Literature

40results about How to "Avoid overhydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective hydrogenation catalyst and application thereof and hydrogenation process of C-2 fraction in production of ethylene by steam cracking

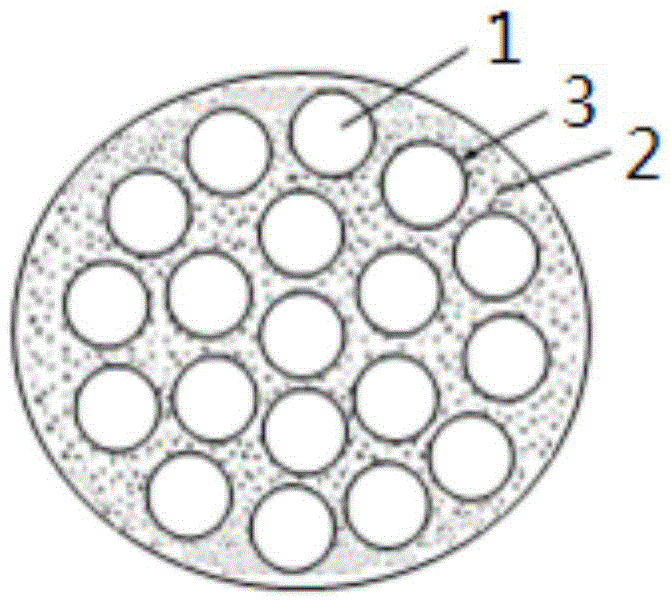

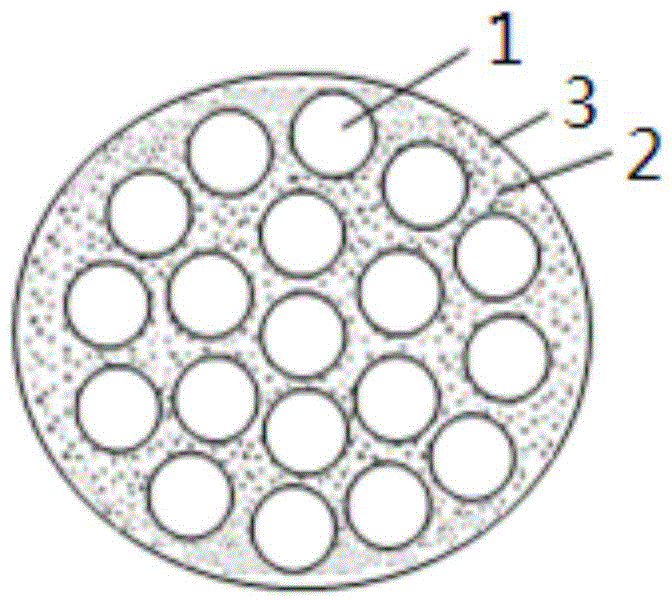

ActiveCN108014832AInhibit Deep AggregationPromote aggregationPhysical/chemical process catalystsHydrocarbon by hydrogenationActive componentPartial hydrogenation

The invention belongs to the field of catalyst hydrogenation, and specifically provides a selective hydrogenation catalyst and application thereof and a hydrogenation process of a C-2 fraction in production of ethylene by steam cracking. The selective hydrogenation catalyst comprises a catalyst support, a main active component and an optional co-active component, wherein the catalyst support is aP and Sb modified porous inorganic oxide support; the active component comprises Pd And Ag; the selective hydrogenation catalyst for the hydrogenation process of the C-2 fraction comprises 0.01 to 1.0wt% of P, 0.01 to 1.0 wt% of Sb, and 0.001 to 0.1 wt% of Pd, and the weight ratio of Ag / Pd is 3:1 to 20:1. The catalyst has a complex function of selective hydrogenation and partial hydrogenation ofethylene acetylene dimerization, thereby improving the yield of 1,3-butadiene in the hydrogenation reaction of the C-2 fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

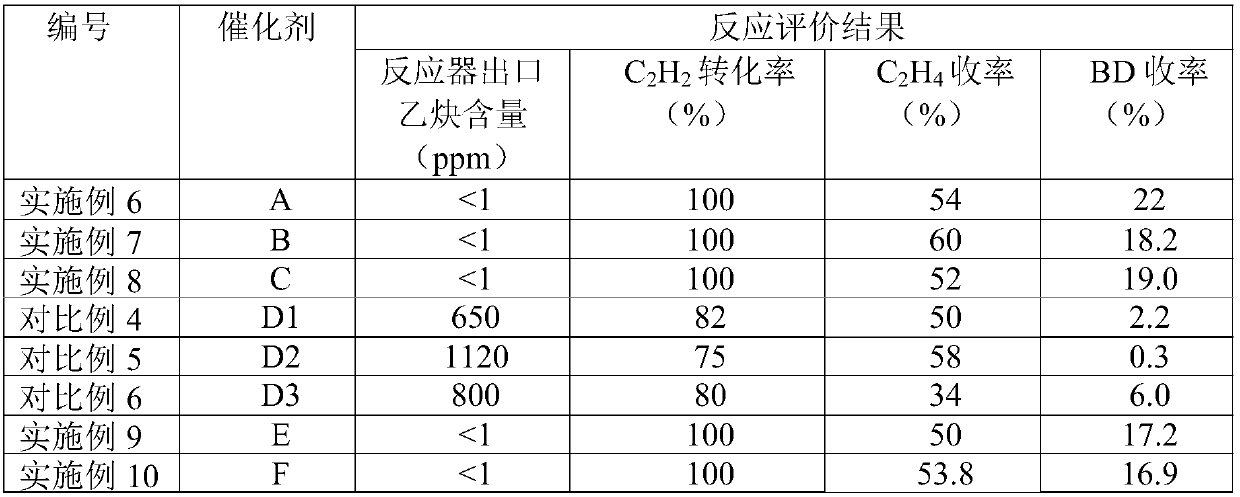

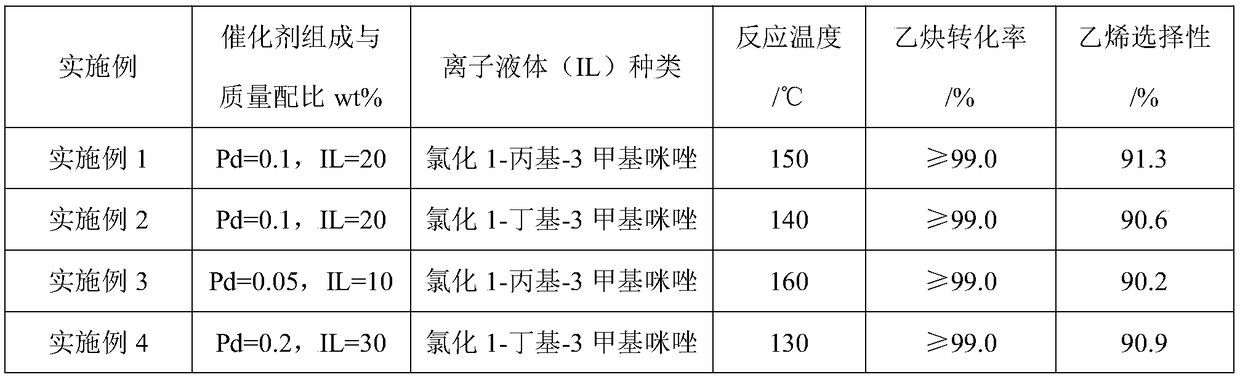

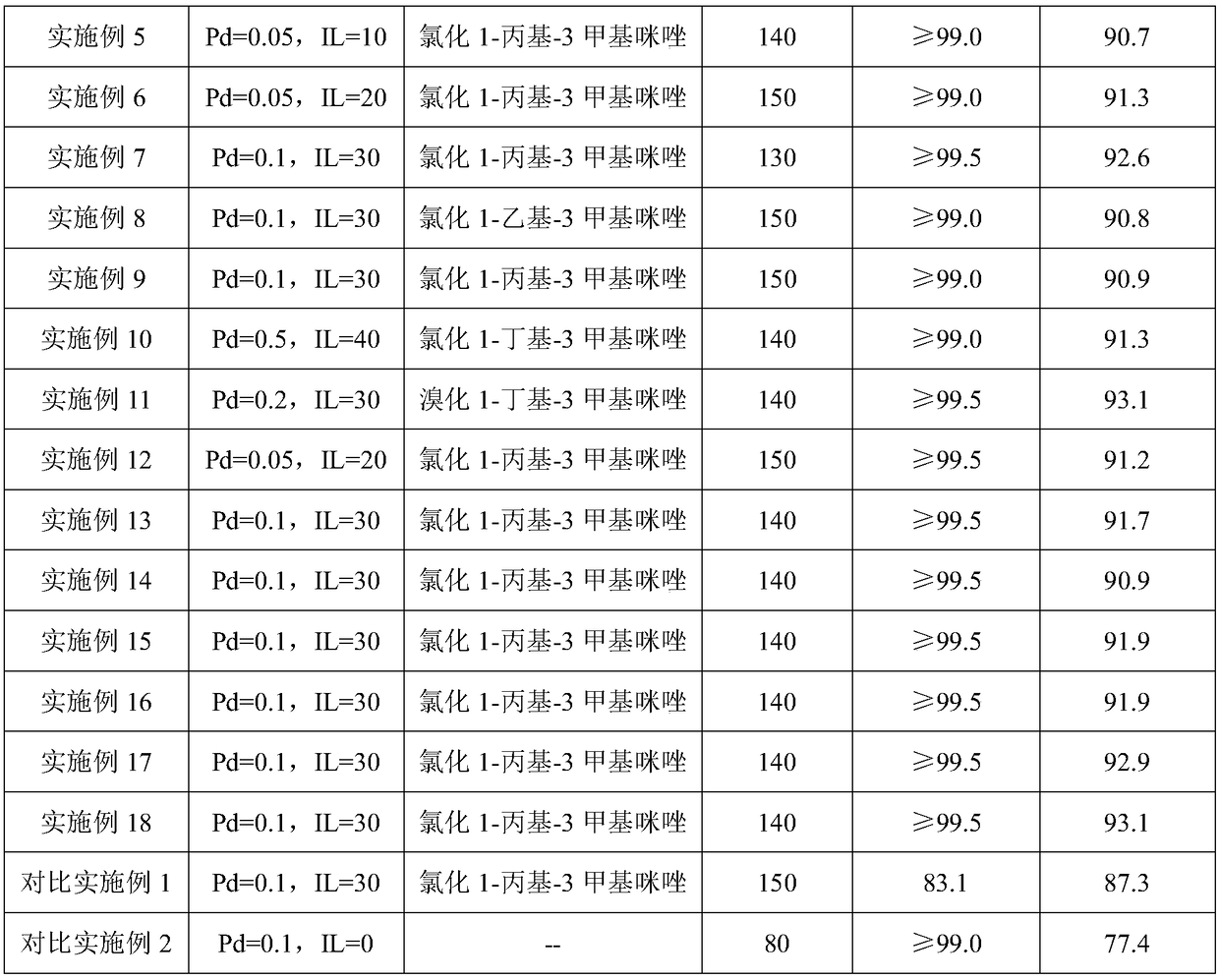

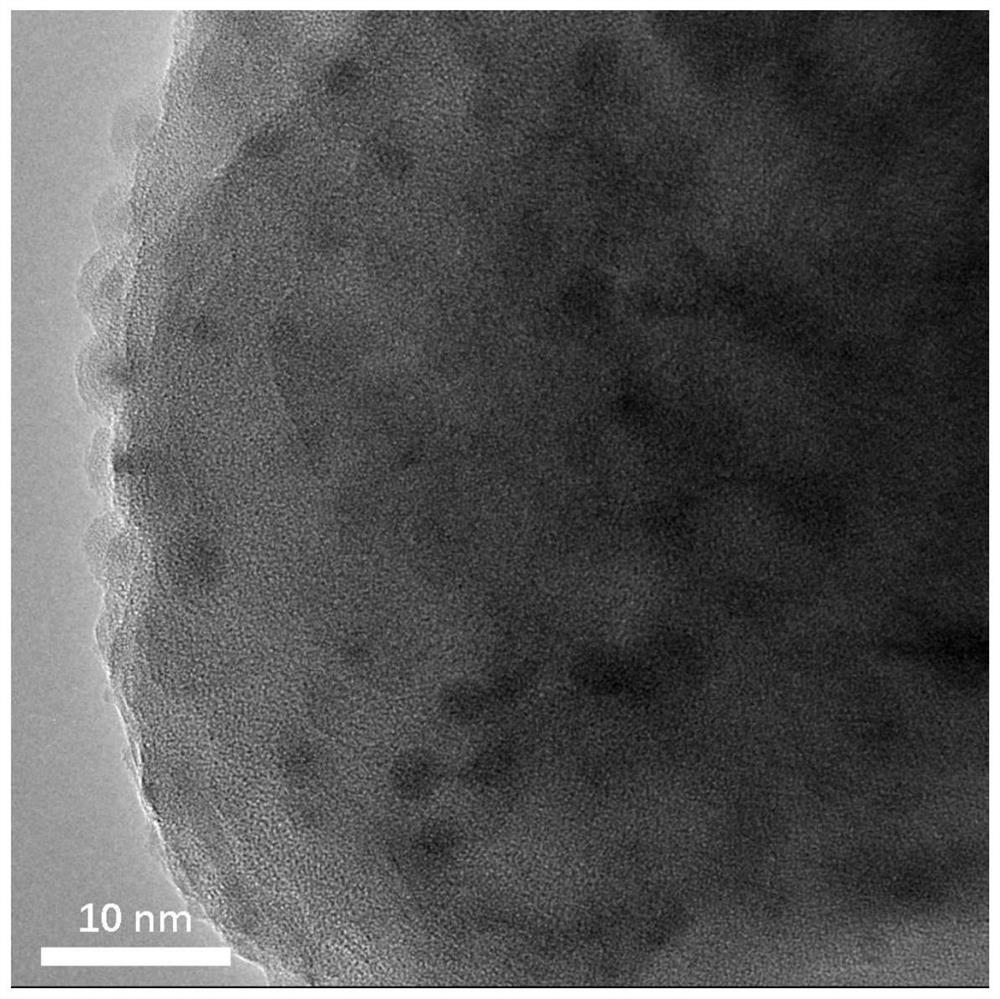

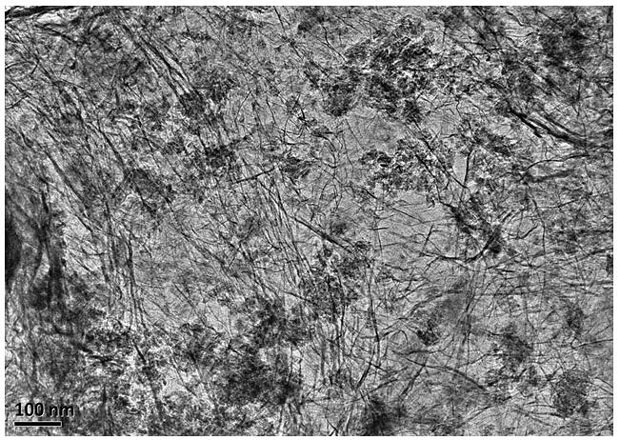

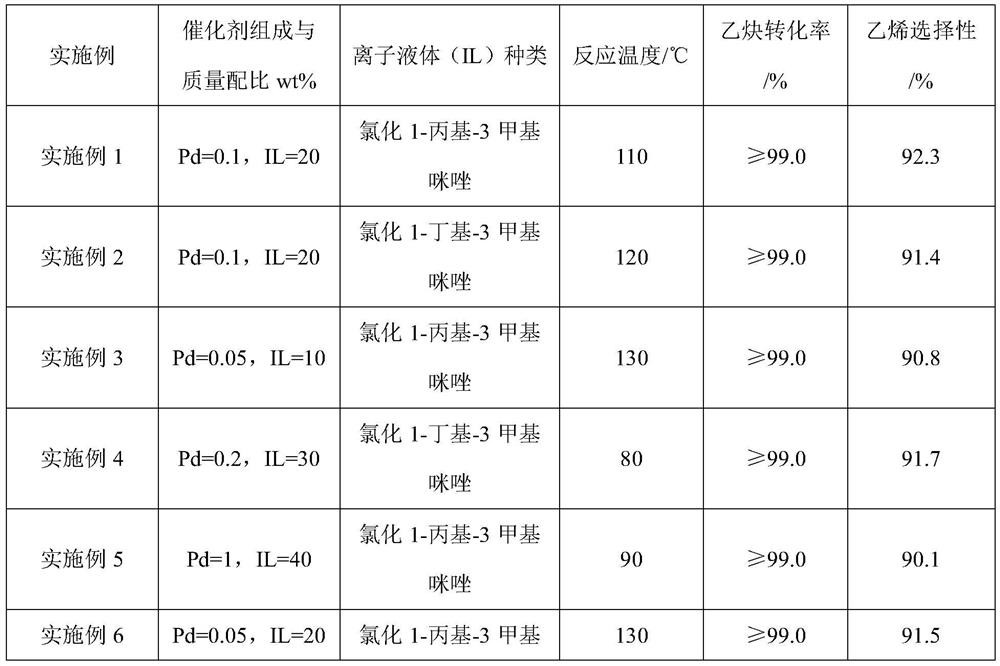

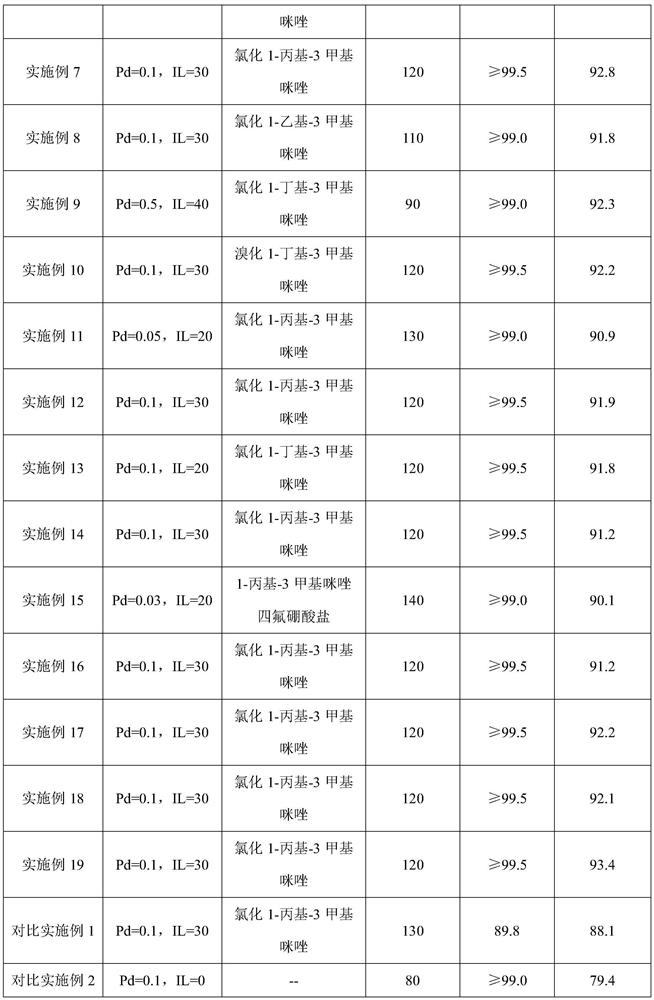

Preparation method of highly dispersed Pd-IL/Al2O3 catalyst and application of same in selective hydrogenation reaction of acetylene

ActiveCN109078655AImprove conversion rateAvoid overhydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrogenationIonSolvent

The invention discloses a preparation method of a highly dispersed Pd-IL / Al2O3 catalyst and an application of the same in selective hydrogenation reaction of acetylene. The preparation method includesthe steps of 1), solving a precursor with a solvent to prepare a corresponding palladium compound impregnation solution; 2), evenly pouring an alumina carrier to the impregnation solution according to the requirement that the load of palladium, impregnating the alumina carrier in the impregnation solution, performing uniform dispersion by ultrasound, impregnating the impregnated carried at the room temperature and then drying an obtained product; 3), placing the dried product A in a tube furnace at the temperature of 200-800DEG C for 1-3 hours to obtain a Pd / Al2O3 catalyst; 4), weighing ionicliquid according to the requirement that the load of the ionic liquid is 10%-40%, dissolving the ionic liquid in deionized water, weighing the Pd / Al2O3 catalyst after even stirring, pouring the Pd / Al2O3 catalyst in a evenly stirred solution, performing uniform dispersion by ultrasonic, impregnating the impregnated carrier in the room temperature, and then performing drying to obtain the Pd-IL / Al2O3 catalyst. The Pd-IL / Al2O3 catalyst obtained is applied to the selective hydrogenation reaction of the acetylene, and excellent catalytic performance is achieved.

Owner:ZHEJIANG UNIV OF TECH

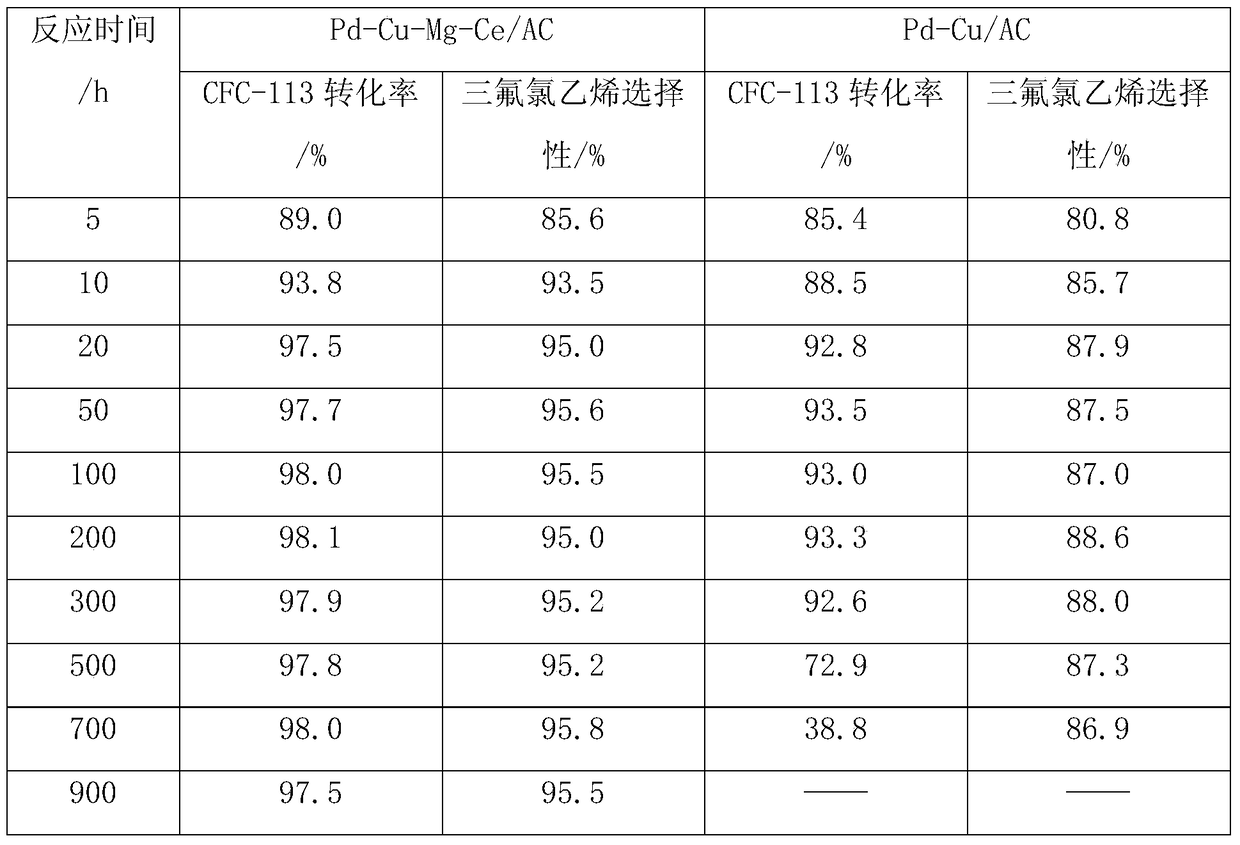

A kind of hydrodechlorination catalyst and its application in the preparation of chlorotrifluoroethylene

ActiveCN105457651BHigh selectivityExtend your lifePreparation by dehalogenationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonAdjuvant

The invention discloses a hydrodechlorination catalyst. The hydrodechlorination catalyst consists of main catalysts, an adjuvant and a carrier, wherein the main catalysts are Pd and Cu, the adjuvant is selected from one or a combination of two or three or more of Mg, Ca, Ba, Co, Mo, Ni, Sm and Ce, and the main catalysts and the adjuvant are loaded onto the activated carbon carrier. The hydrodechlorination catalyst provided by the invention is applicable to the preparation of chlorotrifluoroethylene from CFC-113 through catalytic hydrodechlorination and has the advantages of long service life, high chlorotrifluoroethylene selectivity and the like.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

Preparation method and application of oxidization modified carbon nanotube-loaded double-metal copper and magnesium co-doped nickel-based multi-metal catalyst

ActiveCN107469825AImprove hydrogenation activityWeaken energyCarboxylic acid nitrile preparationOrganic compound preparationModified carbonNanotube

The invention discloses a preparation method and application of an oxidization modified carbon nanotube-loaded double-metal copper and magnesium co-doped nickel-based multi-metal catalyst. A multi-wall carbon nanotube loaded multi-metal nickel-based catalyst subjected to hydrogen peroxide oxidization is utilized and Cu is introduced so that the reduction energy of a Ni precursor can be effectively reduced and the dispersion of Ni nanoparticles on the surface of the carbon nanotube is accelerated; meanwhile, more Ni<0+> can be formed under the synergistic effect of Cu and Ni. Mg is introduced so that a large quantity of alkaline sites are provided for the surface of the catalyst; meanwhile, a NiO-MgO co-solution is formed so that excessive hydrogenation of reactants is easy to inhibit and excessive byproducts are not formed. Oxidization treatment of the carbon nanotube can be used for further accelerating a strong mutual effect of the carbon tube and active components, so that the hydrogenation activity of the catalyst is greatly improved; the catalyst is used for adiponitrile hydrogenation reaction and relatively high conversion ratio and total selectivity of products can be obtained.

Owner:XIANGTAN UNIV

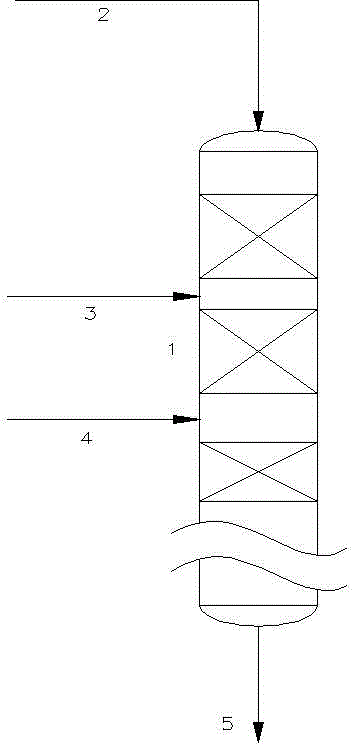

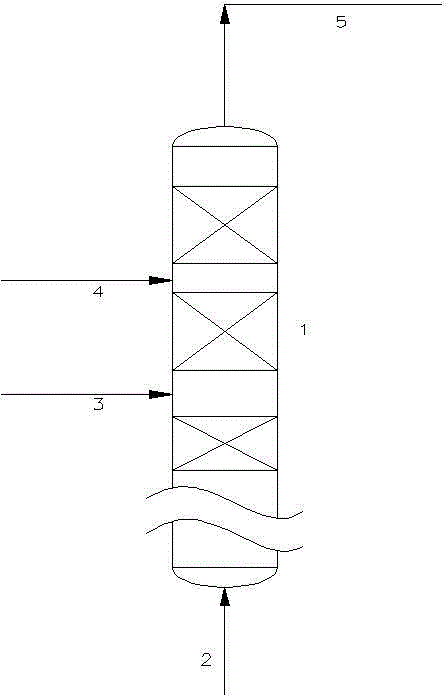

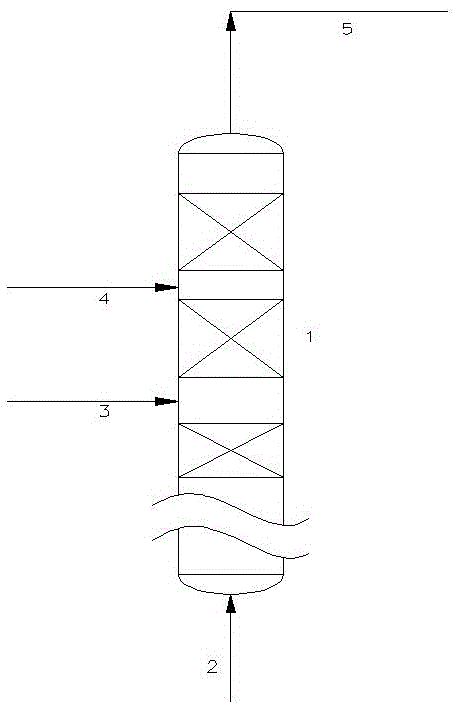

Hydrogenation technology for producing hydrogen peroxide by anthraquinone process

ActiveCN104418308AAvoid overhydrogenationImprove quality levelPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogenation reactionAnthraquinone process

The invention discloses a hydrogenation technology for producing hydrogen peroxide by an anthraquinone process, which comprises the following steps: operating fluid and hydrogen-containing gas in the hydrogenation technology for producing hydrogen peroxide by the anthraquinone process are introduced in a reactor along flowing direction of materials in the reactor, a hydrogenation reaction is carried out on a bed layer of a catalyst, each strand of operating fluid corresponds a strand of hydrogen-containing gas, wherein hydrogen-containing gas is divided into 2-10 strands, the strand number of operating fluid is less than that of the hydrogen-containing gas, The last strand of the material long the flowing direction of the material is the hydrogen-containing gas. The technology can effectively avoid the excessive hydrogenation, increase hydrogen effect and prolong the usage life of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

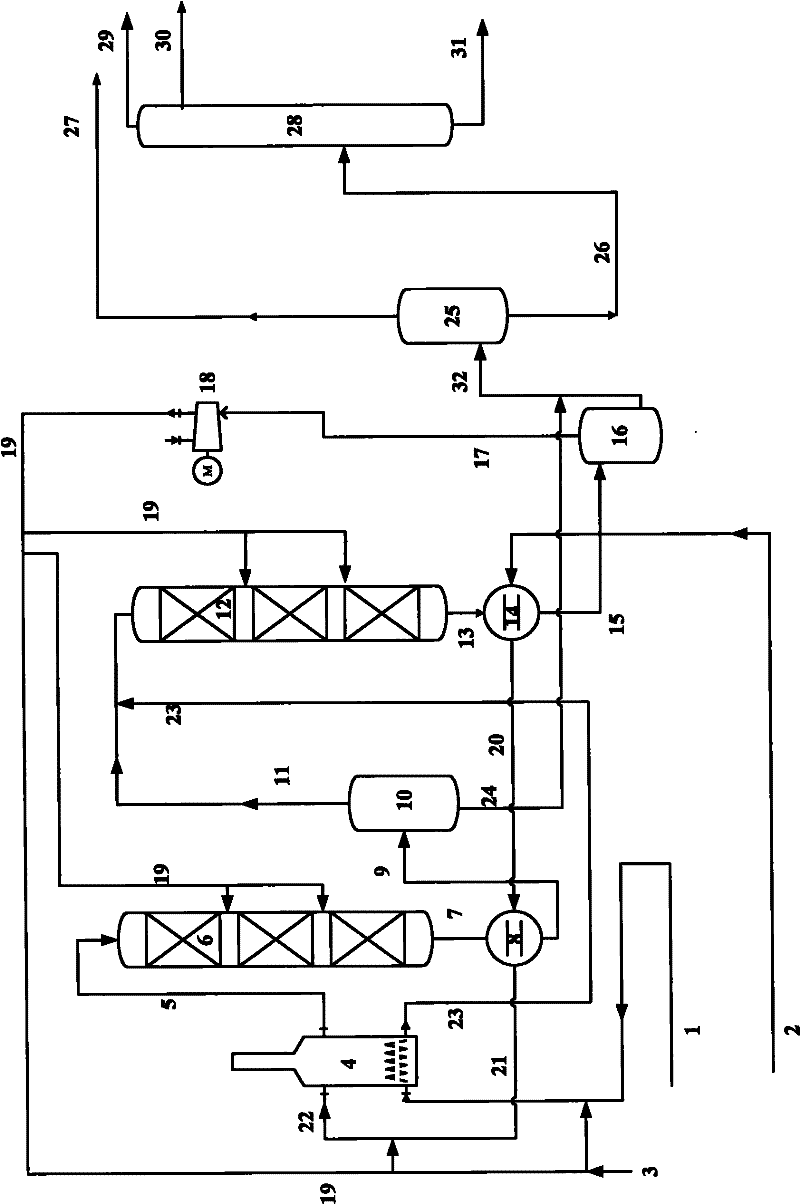

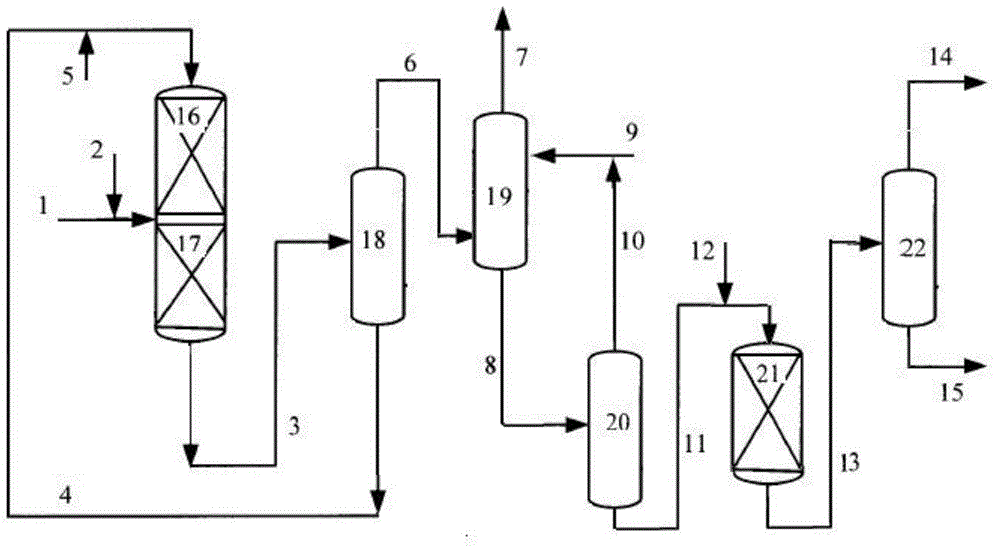

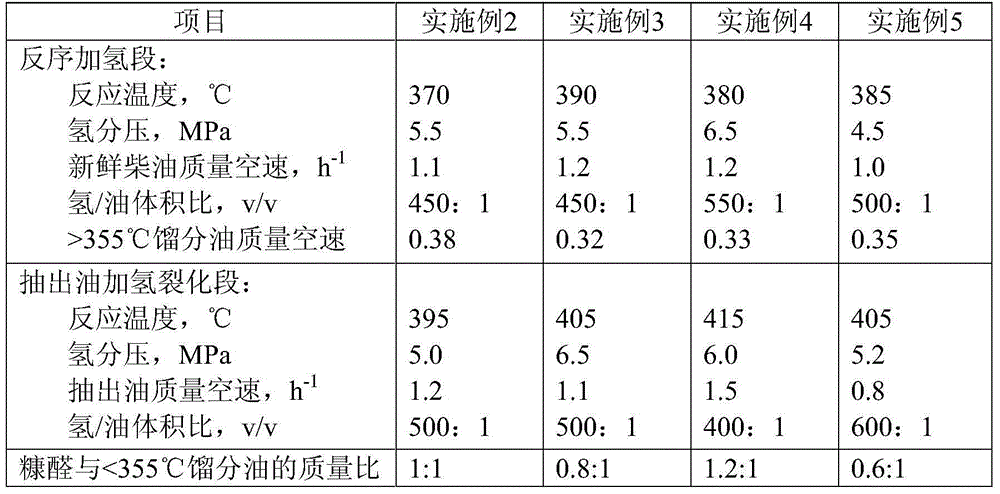

Method for combining coal tar fractional distillation and hydro-conversion

InactiveCN101629105AReduce total usageGood choiceTreatment with hydrotreatment processesCombined methodFractional distillation

The invention relates to a method for combining coal tar fractional distillation and hydro-conversion. Initial coal tar extracts a first fraction and a second fraction which have different boiling ranges in coal tar extraction parts; and the first fraction enters a first hydro-conversion part and the second fraction enters a second hydro-conversion part. By selecting each suitable hydro-conversion operation condition on fractions with different boiling ranges, the method has the advantages of optimized operation condition, stable operation, catalyst usage reduction, and operation period extension, and is particularly suitable for the large-scale hydro-conversion of full fraction coal tar.

Owner:何巨堂

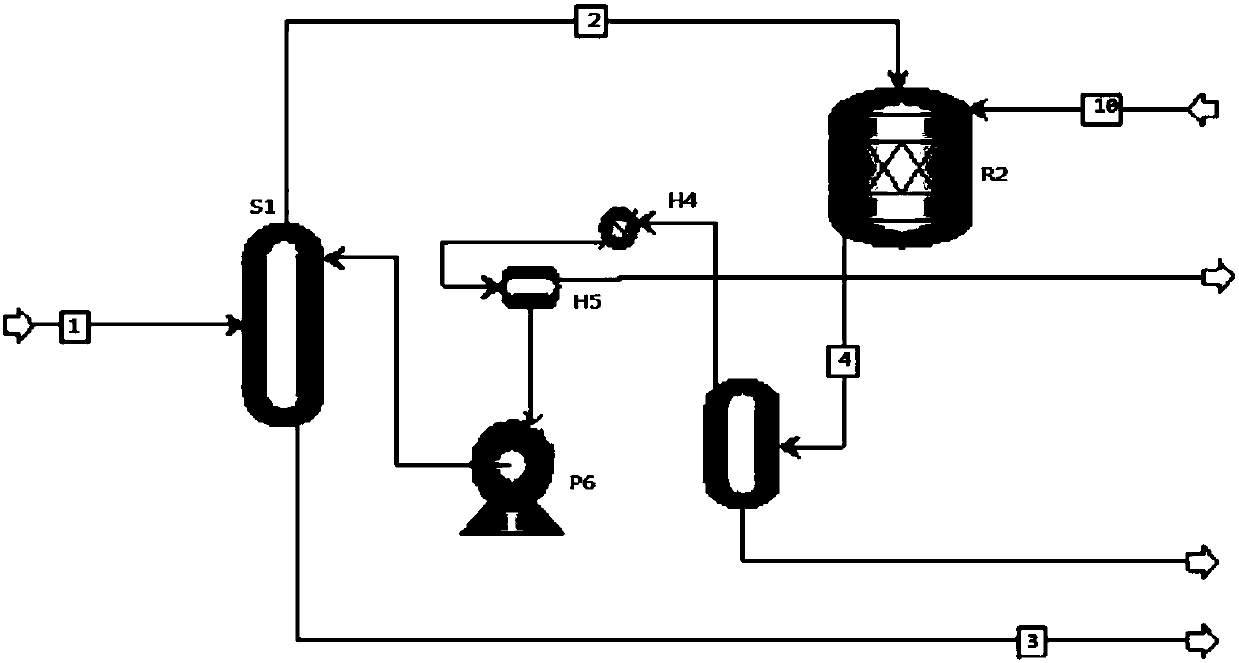

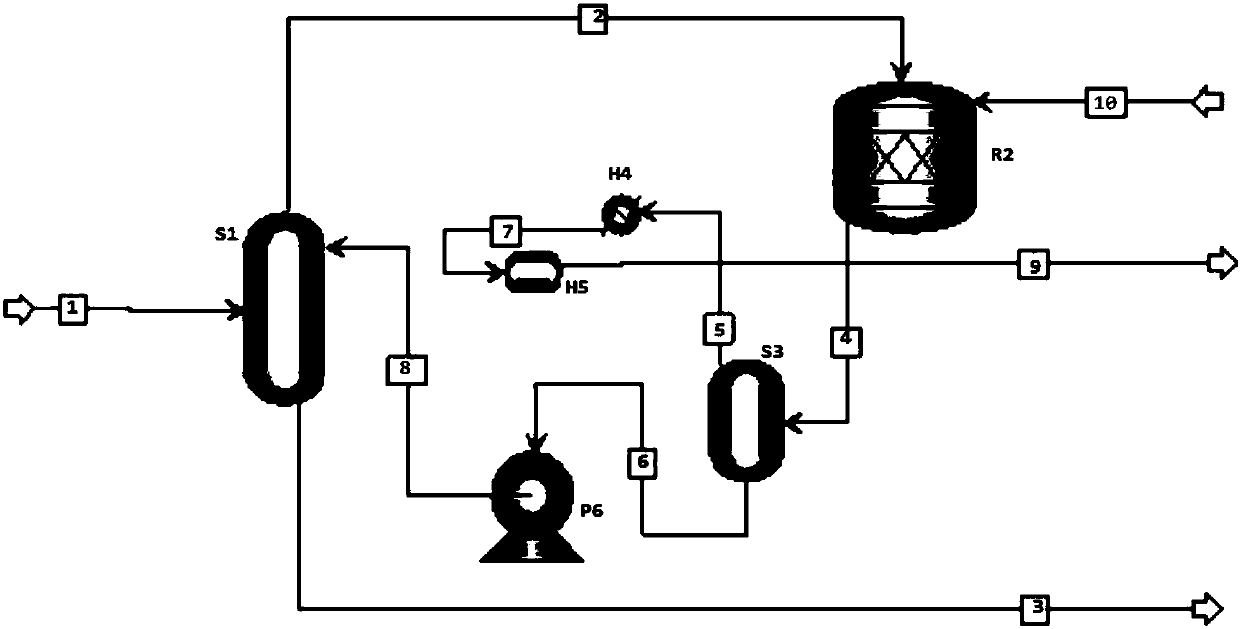

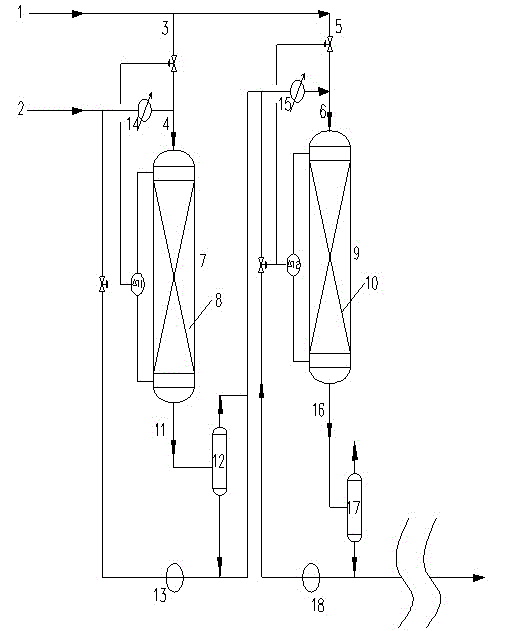

Hydrogenation process for producing hydrogen peroxide by anthraquinone method

ActiveCN104555935APrevent deficienciesAvoid excessive hydrogenation reactionsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesGas phaseHydrogenation process

The invention discloses a hydrogenation process for producing a hydrogen peroxide by an anthraquinone method. The hydrogenation process comprises the following steps that: (1) two reactors are arranged in the hydrogenation process for producing the hydrogen peroxide by the anthraquinone method; a first current of fresh hydrogen and a working liquid serve as a feeding material I and perform hydrogenation in the first reactor; the reacted material is subjected to gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the first reactor; the rest of the liquid phase is reasonably optimized and modulated; the phenomenon that the reaction hydrogen is deficient or excessive is avoided; the hydrogenation completeness is realized; the liquid phase and the gas phase are mixed to serve as feeding material II and enter the second reactor; (2) a second current of fresh hydrogen and the feeding material II perform the hydrogenation in the second reactor; the reacted material is subjected to the gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the second reactor, and the rest of the liquid phase enters an oxidation process. According to the process disclosed by the invention, a hydrogenation process is optimized, and meanwhile, side effects are reduced, so that the hydrogenation is more uniform, and the service life of a catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

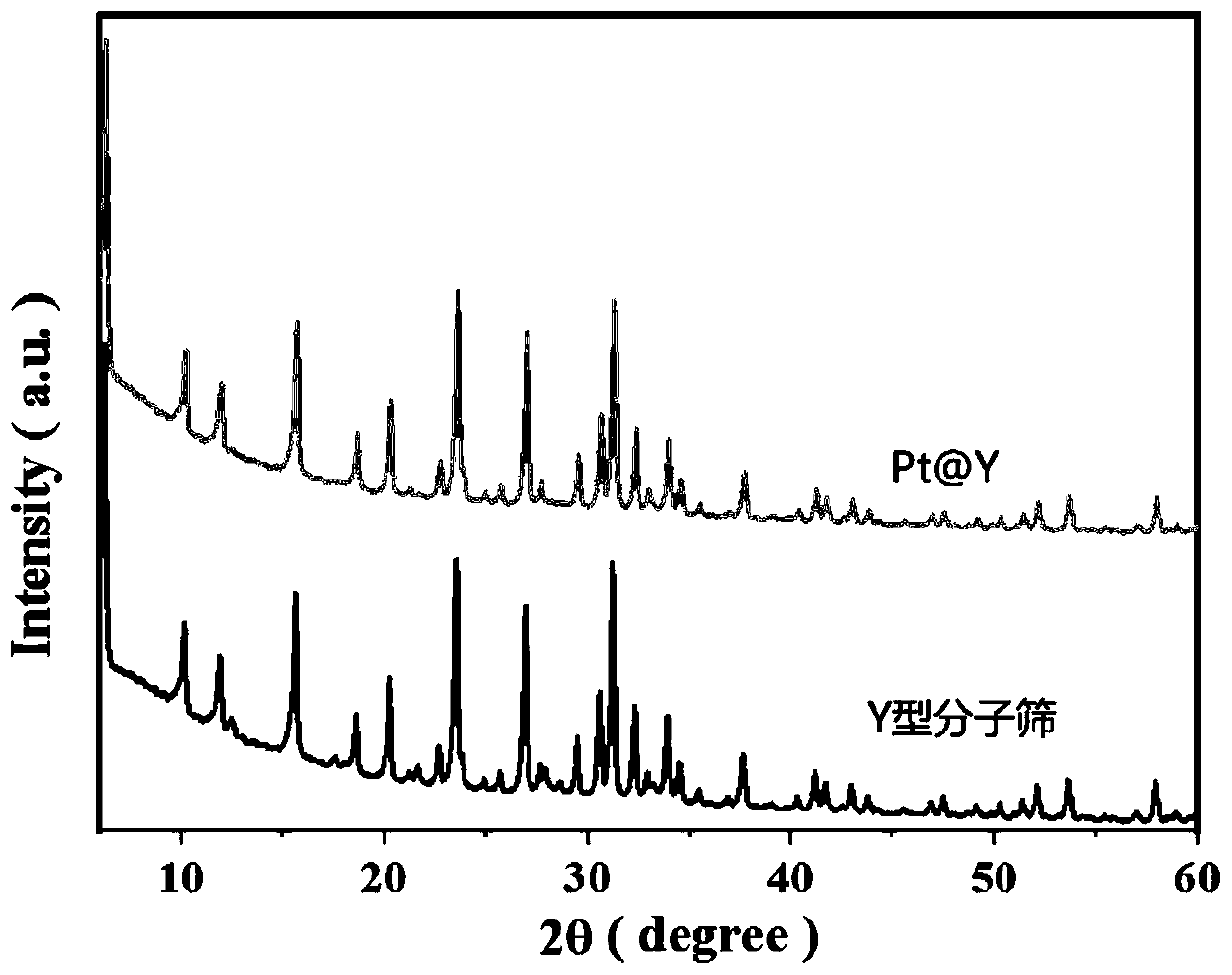

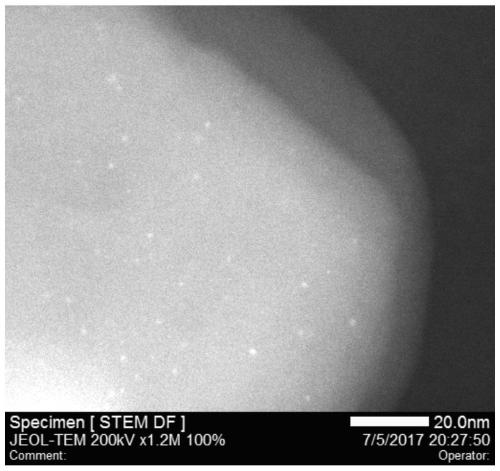

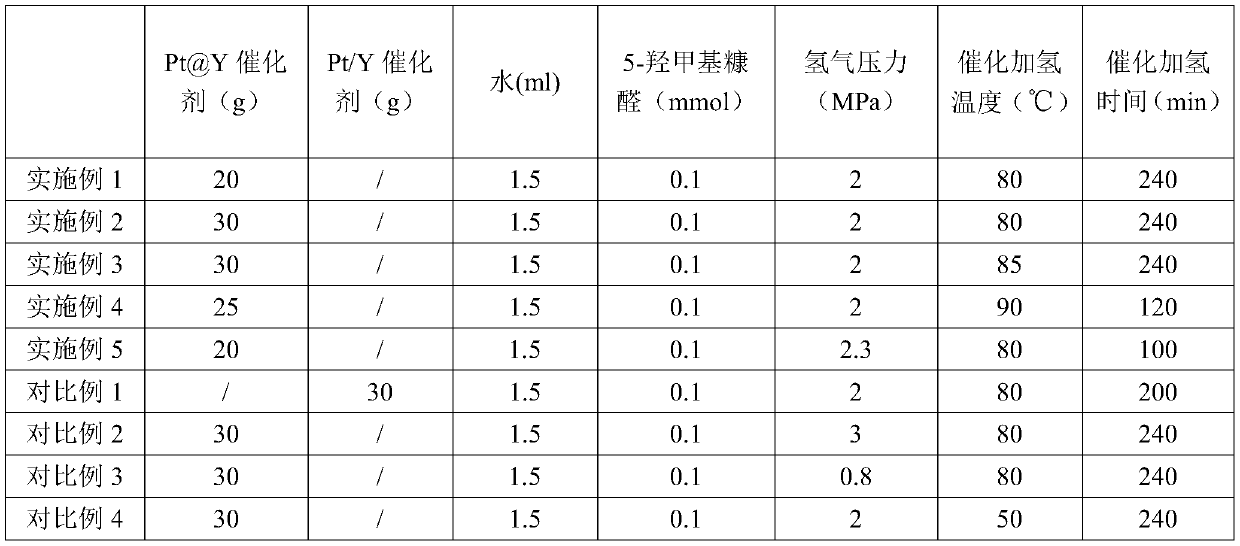

Preparation method of 2, 5-furandimethanol

ActiveCN111574483AHydrogenation rate decreasedAvoid overhydrogenationOrganic chemistryMolecular sieve catalystsFuranPtru catalyst

The invention provides a preparation method of 2, 5-furandimethanol. The preparation method comprises the following step of: in a hydrogen atmosphere, carrying out catalytic hydrogenation on 5-hydroxymethylfurfural by using Y molecular sieve-encapsulated nano platinum as a catalyst to obtain 2, 5-furandimethanol. According to the preparation method, catalytic hydrogenation is carried out on the 5-hydroxymethylfurfural by using the Y molecular sieve-encapsulated nano platinum, so that the 5-hydroxymethylfurfural can be adsorbed on the surfaces of platinum particles in an endpoint adsorption conformation instead of a lying adsorption conformation. According to the endpoint adsorption conformation, on one hand, one end of the hydroxyl of the 5-hydroxymethylfurfural is vertically adsorbed, sothat the hydrogenation rate of the hydroxyl is greatly reduced; on the other hand, the hydrogenation rate of the aldehyde group of the 5-hydroxymethylfurfural on the surfaces of the platinum particlesis increased; and therefore, catalytic hydrogenation selectivity higher than 99% can be achieved, and excessive hydrogenation of furan rings is completely avoided.

Owner:SUN YAT SEN UNIV

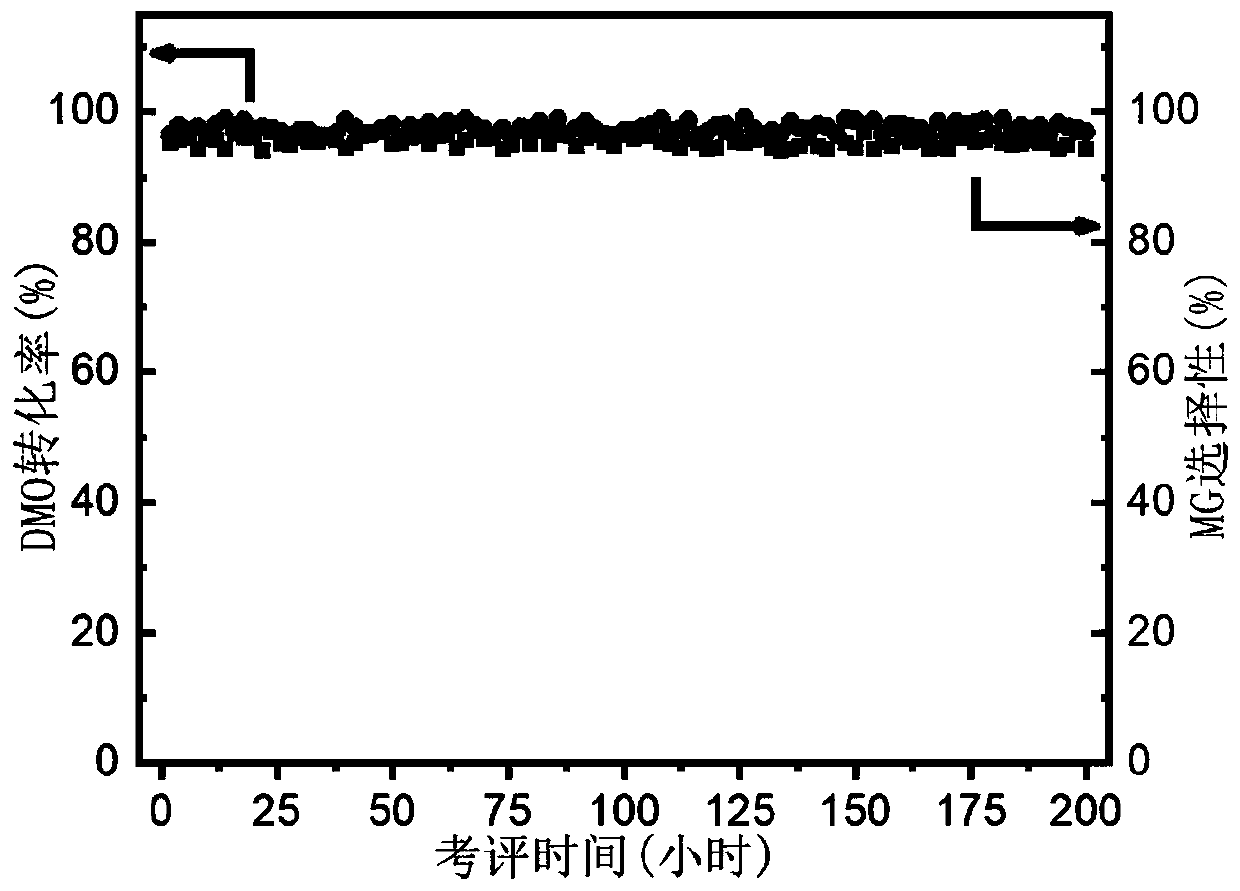

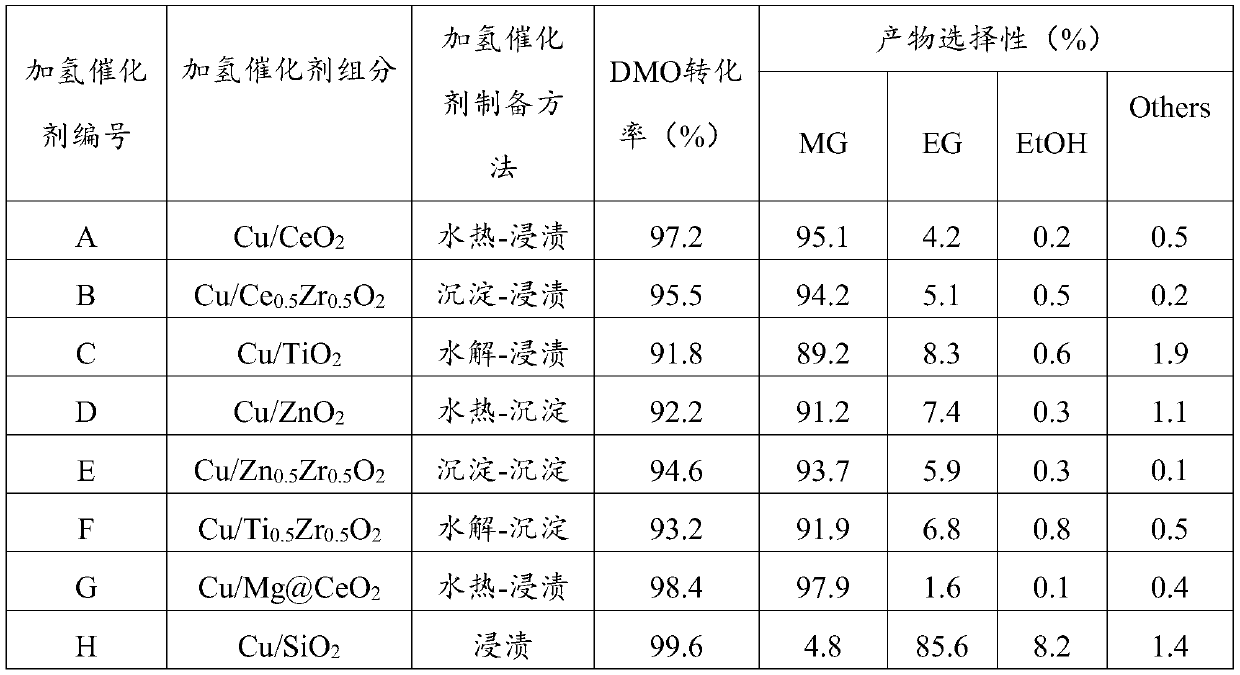

Hydrogenation catalyst and preparation method and application thereof

InactiveCN111569876AReduce aggregationSlow downOrganic compound preparationCarboxylic acid esters preparationPtru catalystPhysical chemistry

The invention relates to the technical field of catalysts, in particular to a hydrogenation catalyst and a preparation method and application thereof. The hydrogenation catalyst comprises a metal oxide carrier and an active component loaded on the metal oxide carrier, wherein the active component comprises a Cu elementary substance and / or an oxide of copper; the metal oxide carrier comprises a subgroup metal oxide or a subgroup composite metal oxide; the subgroup metal oxide comprises cerium oxide, titanium oxide, zirconium oxide or zinc oxide; the subgroup composite metal oxide comprises a composite oxide of two or more of cerium oxide, titanium oxide, zirconium oxide and zinc oxide. When the hydrogenation catalyst is used for catalyzing dimethyl oxalate hydrogenation to directly preparemethyl glycolate, the catalytic activity is high, the selectivity to methyl glycolate is high, and the stability of the structure and the performance of the hydrogenation catalyst in the long-term useprocess is high.

Owner:XIAMEN UNIV

Butadiene product and preparation method thereof

ActiveCN103304360AEfficient manufacturingReduce generationHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionElectron

The invention relates to a butadiene product and a preparation method thereof. The method comprises the following step of: subjecting vinylacetylene to hydrogenation reaction by using a catalyst, wherein in the reaction process, reagents with electron-donating capacity are introduced into a reaction system. Butadiene can be effectively prepared by utilizing the method.

Owner:ANHUI ANQING SHUGUANG CHEM GRP +1

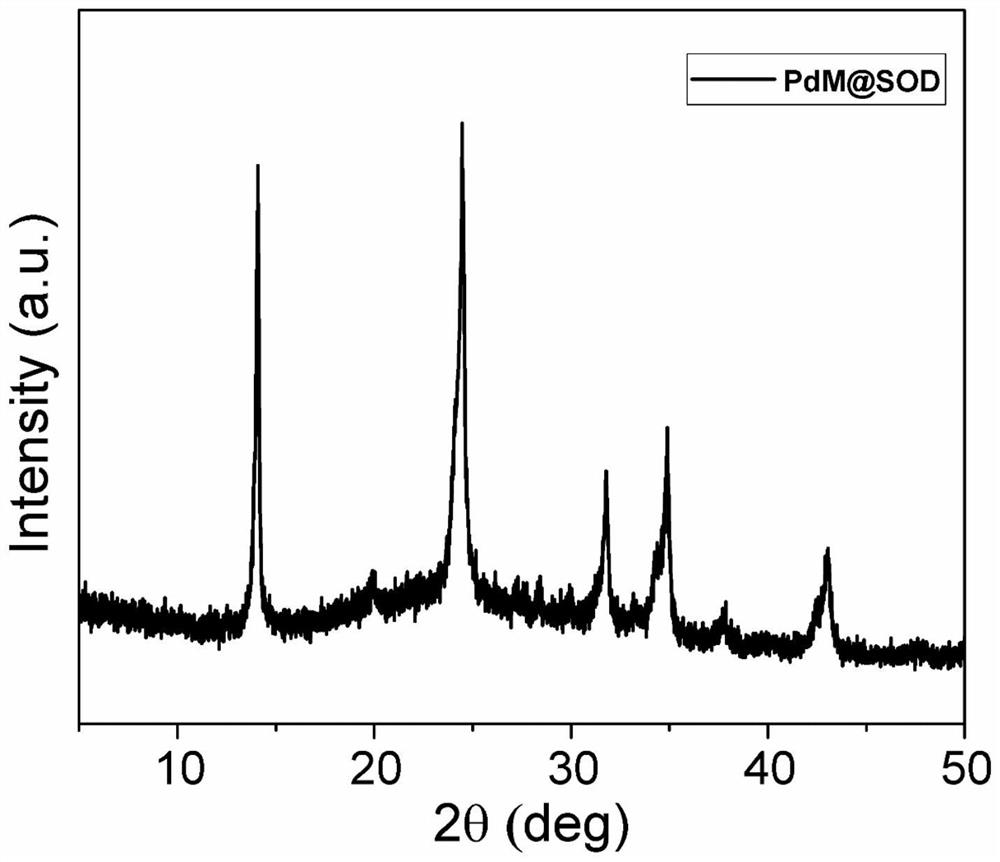

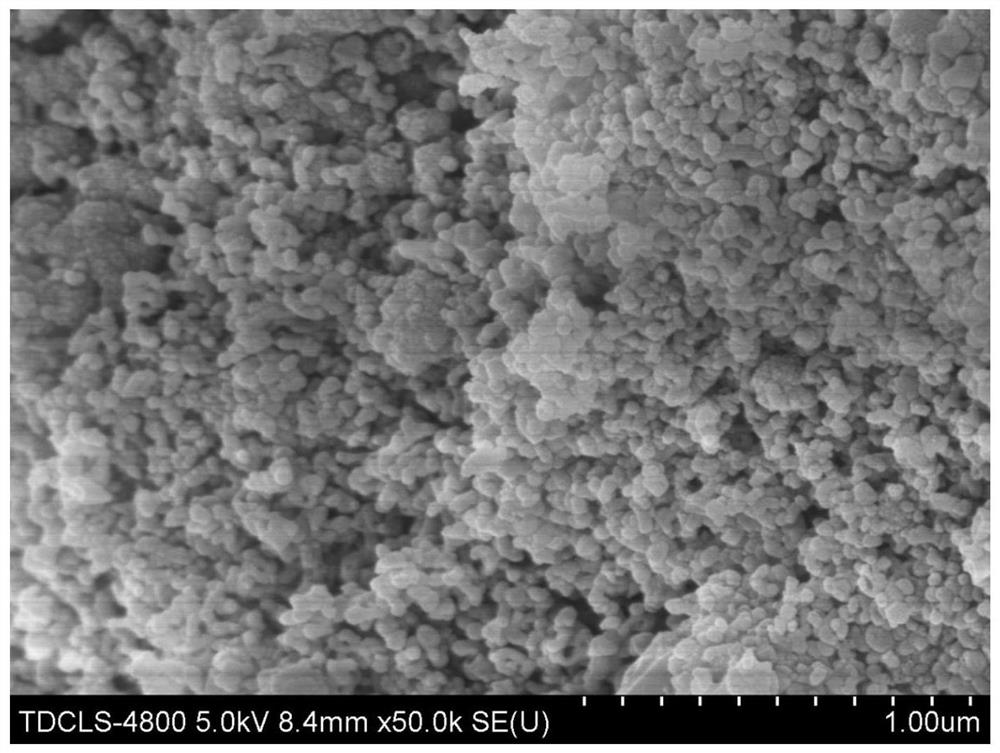

Pd-based alloy packaged molecular sieve catalyst, as well as preparation method and application thereof

ActiveCN112570015AAvoid flying temperatureHydrogenation reaction process safetyMolecular sieve catalystsHydrocarbon by hydrogenationChemistryMolecular sieve

The invention belongs to the technical field of molecular sieve catalysts, and discloses a Pd-based alloy packaged molecular sieve catalyst, a preparation method and applications thereof. The molecular sieve catalyst comprises a sodalite molecular sieve, and PdM nano-alloy particles are packaged in the sodalite molecular sieve; the preparation method comprises the following steps: firstly preparing a sodalite molecular sieve, then impregnating and loading Pd metal and an M metal precursor, roasting and reducing to form a molecular sieve catalyst impregnated and loaded with nano alloy particles; then uniformly mixing with a silica-alumina sol solution, uniformly stirring and mixing the solution, evaporating the solution to dryness, then adding ethylene glycol, grinding the mixture into uniform paste, carrying out hydrothermal reaction, and cooling, washing, drying, roasting and reducing the reaction product to obtain the catalyst. The molecular sieve catalyst is applied to acetylene selective hydrogenation reaction, can avoid an excessive hydrogenation process, and has relatively high acetylene conversion rate and ethylene selectivity.

Owner:TIANJIN UNIV

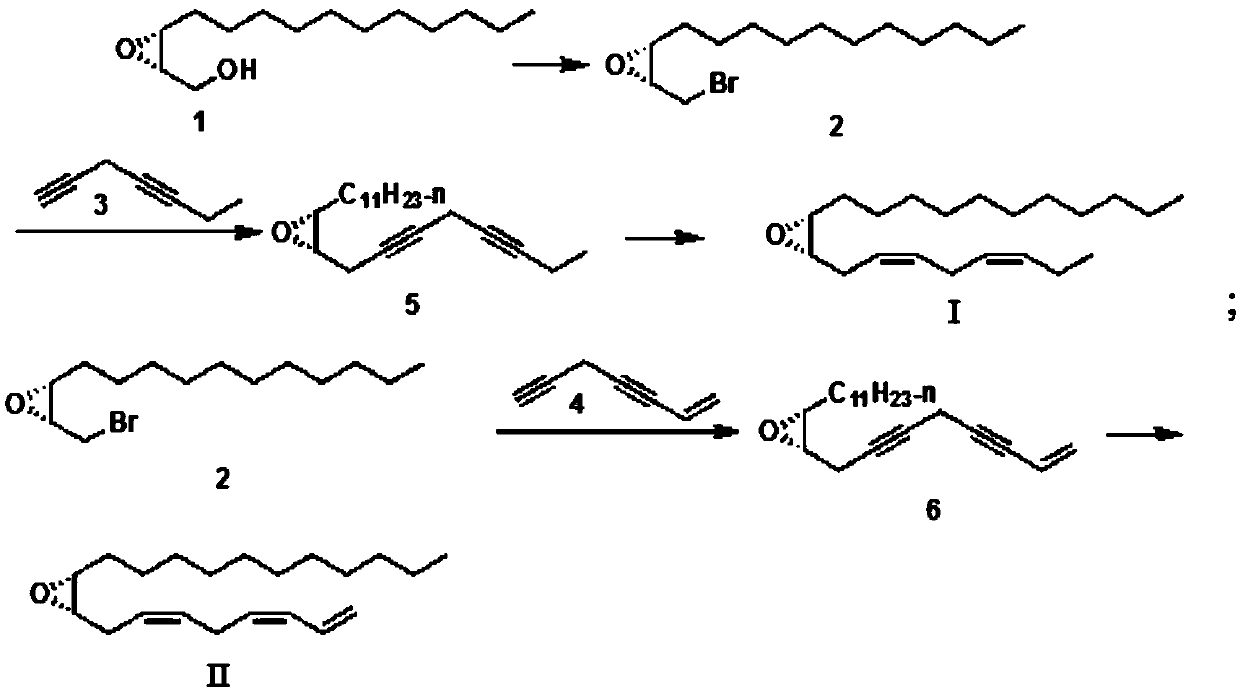

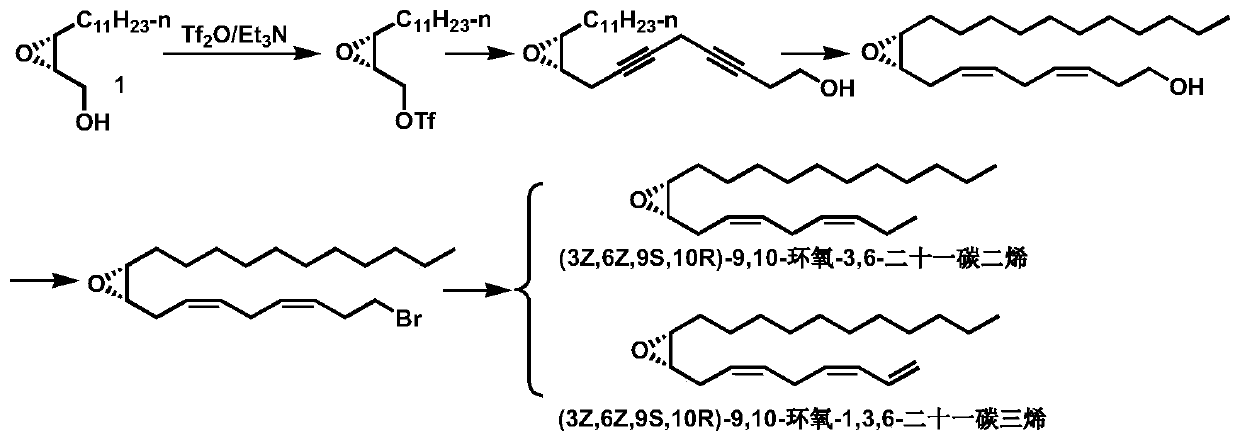

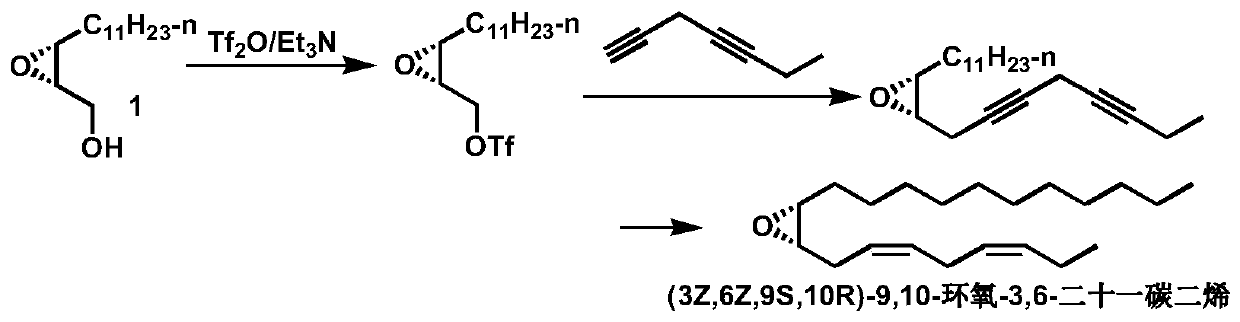

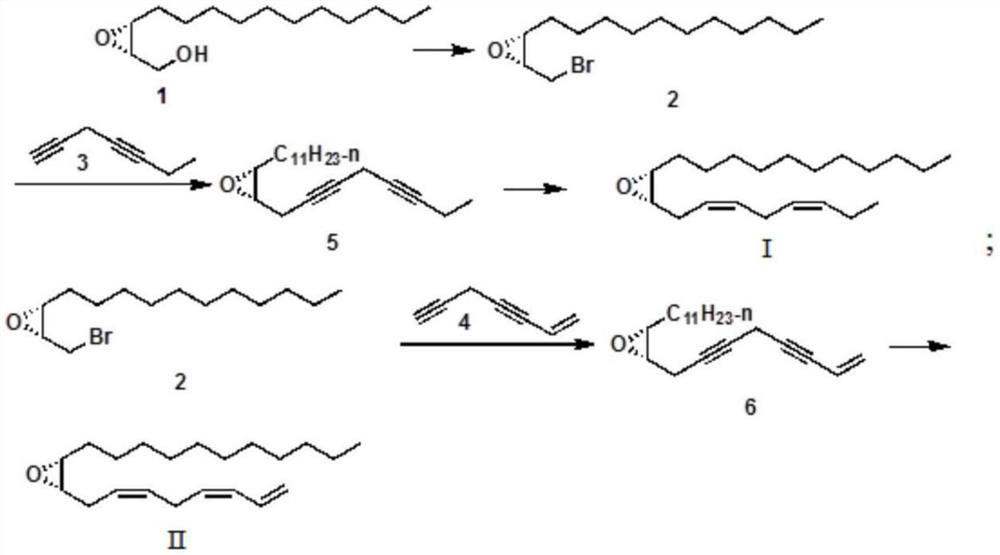

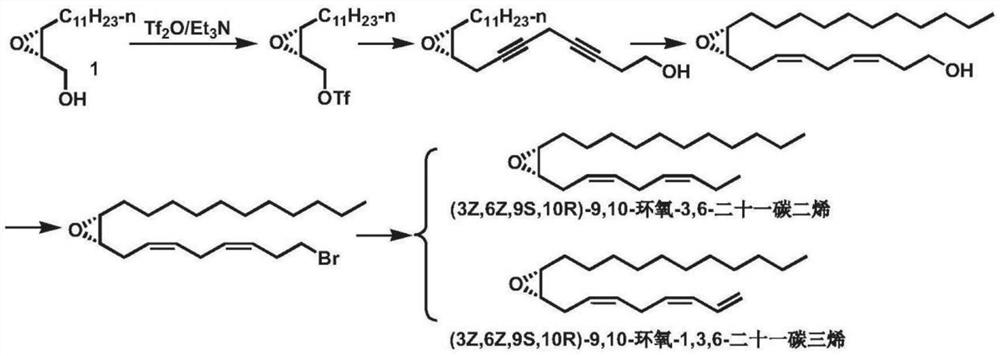

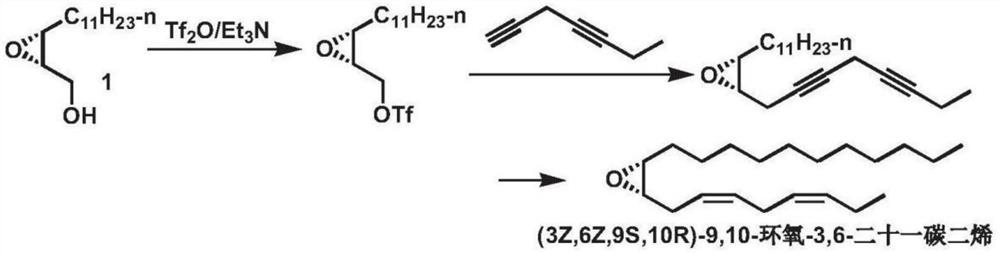

Synthetic method of hyphantria cunea sex pheromone components

ActiveCN110845447AHigh yieldFew reaction stepsPest attractantsOrganic chemistry methodsEpoxySexual Pheromones

The invention discloses a synthetic method of hyphantria cunea sex pheromone components, and belongs to the technical field of chemical production. (2S, 3R)-2, 3-epoxy-1-tetradecanol is used as a rawmaterial, and the hyphantria cunea sex pheromone components (3Z, 6Z, 9S, 10R)-9, 10-epoxy-3, 6-heneicosadiene and (3Z, 6Z, 9S, 10R)-9, 10-epoxy-1, 3, 6-heneicosatriene are obtained through bromination, coupling and hydrogenation. The process is mild and controllable in reaction, good in yield, simple and convenient to operate, few in reaction steps, low in production cost and suitable for large-scale production. The lure prepared from the sex pheromone components synthesized by the synthesis method can effectively trap and kill a large number of hyphantria cunea male moths in combination witha trap, is applied to hyphantria cunea pest situation forecasting and green prevention and control, and can reduce chemical pesticide application, thereby reducing pollution, protecting the environment and remarkably improving economic, social and ecological comprehensive benefits.

Owner:NANJING FORESTRY UNIV

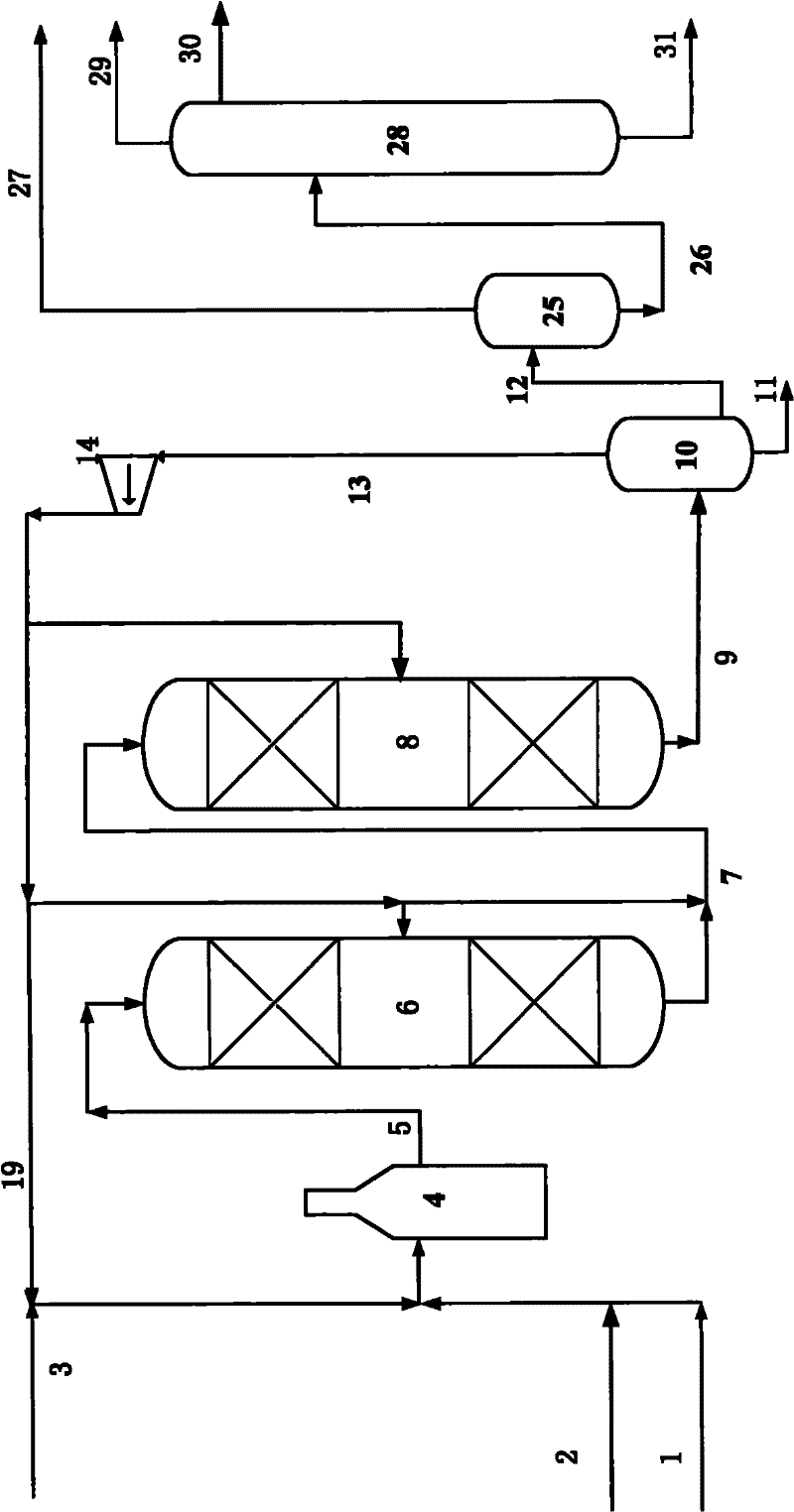

Integrated hydrogenation method for producing clean diesel

ActiveCN102453536AHigh selectivityHigh yieldTreatment with hydrotreatment processesFractionationHigh pressure

The invention discloses an integrated hydrogenation method for producing clean diesel. The method comprises the following steps of: performing hydrogenation refining on a diesel material with high cetane number in a first hydrogenation reaction area; separating in a thermal high-pressure separator, mixing the separated hydrogen-rich gas and a diesel material with low cetane number, allowing the mixture to enter a second hydrogenation reaction area, performing hydrodesulfurization, hydrodenitrogeneration, aromatics saturation and cycloalkane opening reaction under the action of hydrogenation refining and a hydrocracking catalyst, mixing a liquid-phase material flow obtained by the thermal high-pressure separator and a liquid material in the second hydrogenation reaction area, and allowing the mixture to enter a fractionation system; and finally obtaining the clean diesel and a small amount of naphtha with high aromatic hydrocarbon. By the method, a clean diesel product having the sulfur content of less than 10ppm and the cetane number of more than 51 can be produced. On one set of device, two technological processes are implemented, the flow is relatively simple, the hydrogen utilization rate is high, device investment and operating cost are low, and the process selectivity and economic efficiency are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for hydrogen peroxide preparation through anthraquinone process and method for producing hydrogen peroxide

InactiveCN105800565AReduce wearIncrease solid ratioPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogen peroxideRaw material

The invention discloses a hydrogenation method for hydrogen peroxide preparation through an anthraquinone process and a method for producing hydrogen peroxide. The hydrogenation method includes the steps: (1) injecting a working fluid into a slurry containing a hydrogenation catalyst through pores with the average pore size of nanometer size, and carrying out liquid-slurry mixing, to obtain a mixture containing a first slurry; (2) injecting hydrogen gas into the mixture containing the first slurry through the pores with the average pore size of nanometer size, and carrying out gas-slurry mixing, to obtain a mixture containing a second slurry; and (3) under a hydrogenation reaction condition, carrying out a hydrogenation reaction of the mixture containing the second slurry in a slurry-state bed reactor, and thus obtaining a mixture containing a third slurry. With use of the method, higher conversion rate and hydrogenation efficiency of raw materials can be obtained.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

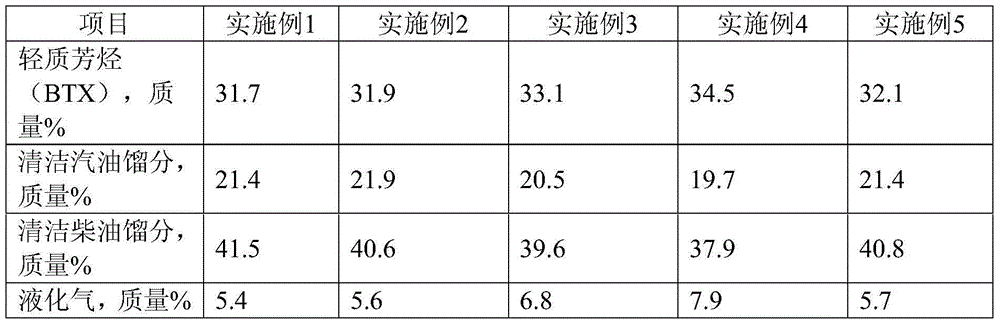

Method for producing light arene product and clean fuel oil product from catalytic cracking diesel oil

ActiveCN103865577BGive full play to the advantagesHigh activityHydrocarbon oil crackingTreatment with hydrotreatment processesAlkaneHydrogen

Owner:CHINA NAT OFFSHORE OIL CORP +2

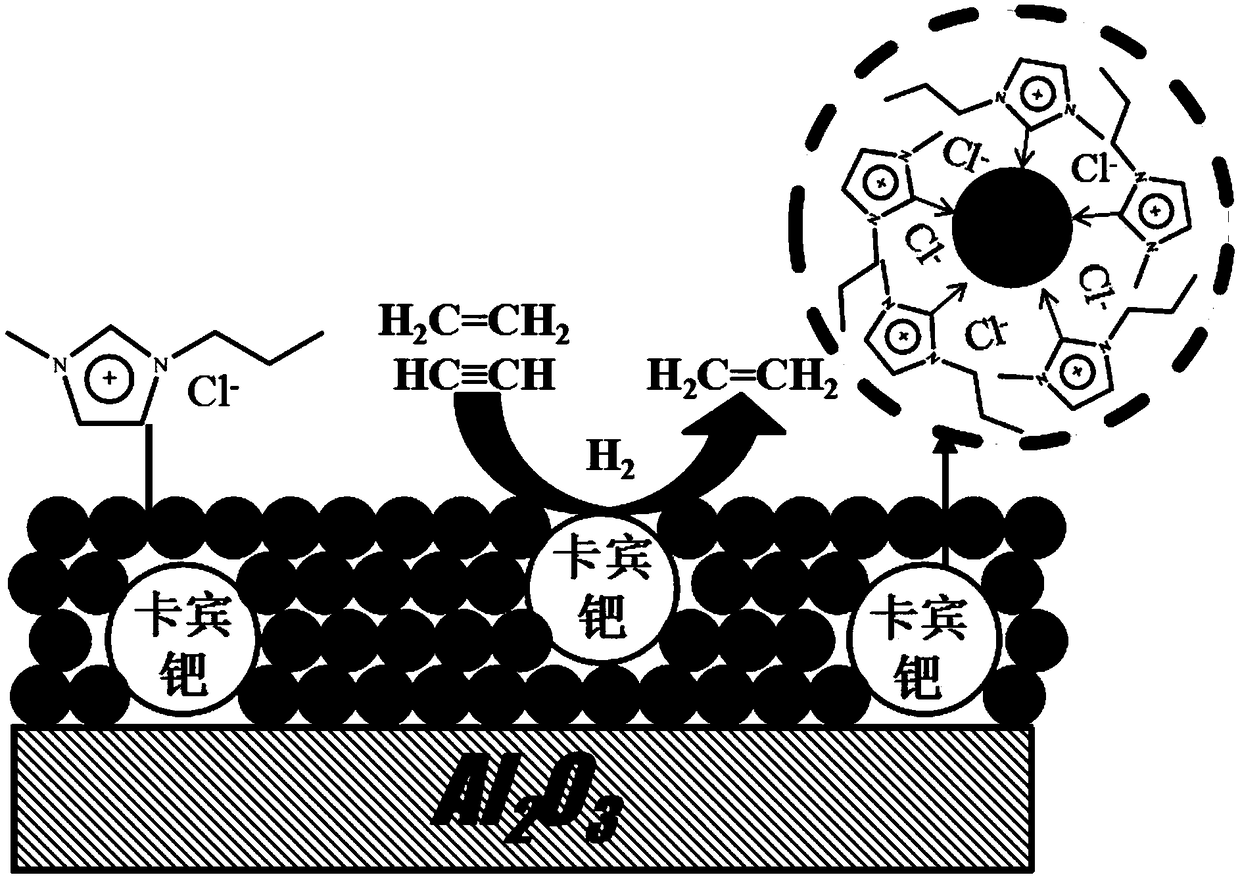

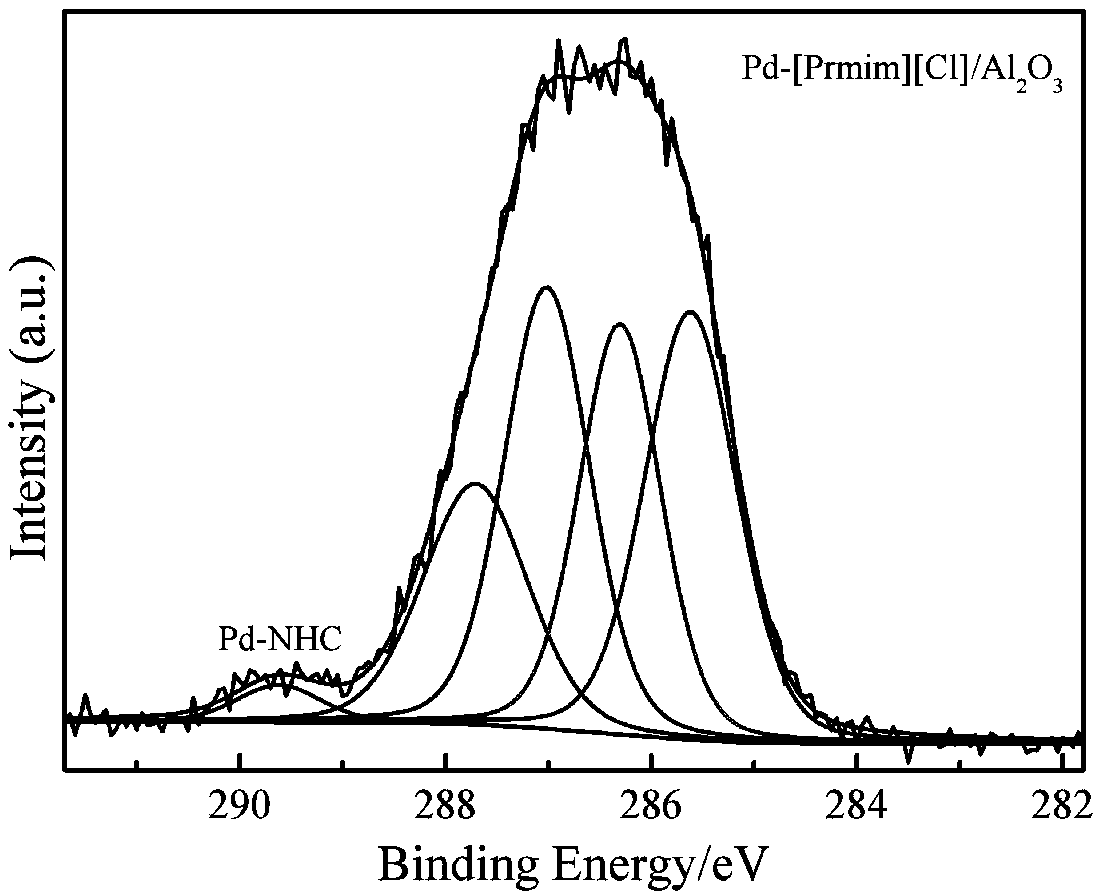

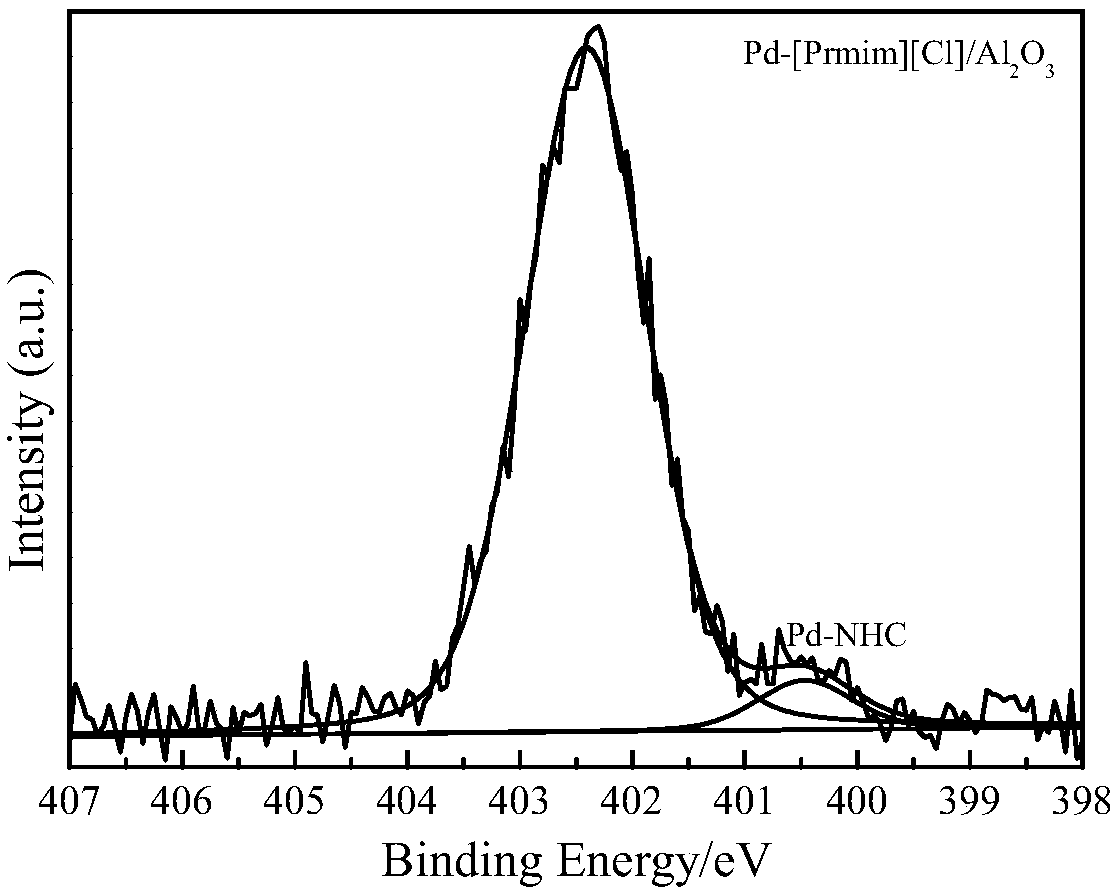

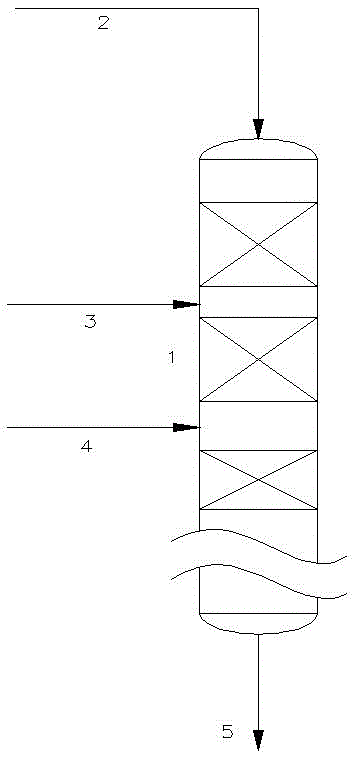

Aluminum oxide loaded ionic liquid-palladium catalyst, preparation thereof and application thereof in front-end hydrogenation reaction of acetylene

ActiveCN109174178AImprove conversion rateReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrogenationPalladium catalystCarbene

The invention discloses an aluminum oxide loaded ionic liquid-palladium catalyst, preparation thereof and application thereof in the front-end hydrogenation reaction of acetylene. The catalyst comprises an aluminum oxide carrier, ionic liquid and a palladium compound, wherein the surface of the aluminum oxide carrier is loaded with the ionic liquid and the palladium compound; the palladium compound is one of chloropalladic acid, palladium nitrate, palladium acetate, palladium acetylacetonate, palladium dichloride, ammonium tetrachloropalladate, sodium chloropalladate, and tetraammine palladiumnitrate; the ironic liquid is selected from imidazole ironic liquid, and anions are chloride ions, bromide ions, hexafluorophosphate, tetrafluorophosphate or (trifluoromethane sulfonyl) imine ions; alayer of liquid film is formed on the surface of the carrier by the ionic liquid, and a carbene structure is further formed by the ionic liquid and the palladium compound; and the loading capacity ofpalladium in the catalyst is 0.01wt%-0.5wt%, and the loading capacity of the ionic liquid is 10wt%-40wt%. The catalyst is applied to the selective front-end hydrogenation of acetylene in a high hydrogen-acetylene ratio, so that the selectivity of acetylene in the reaction can be greatly improved.

Owner:ZHEJIANG UNIV OF TECH

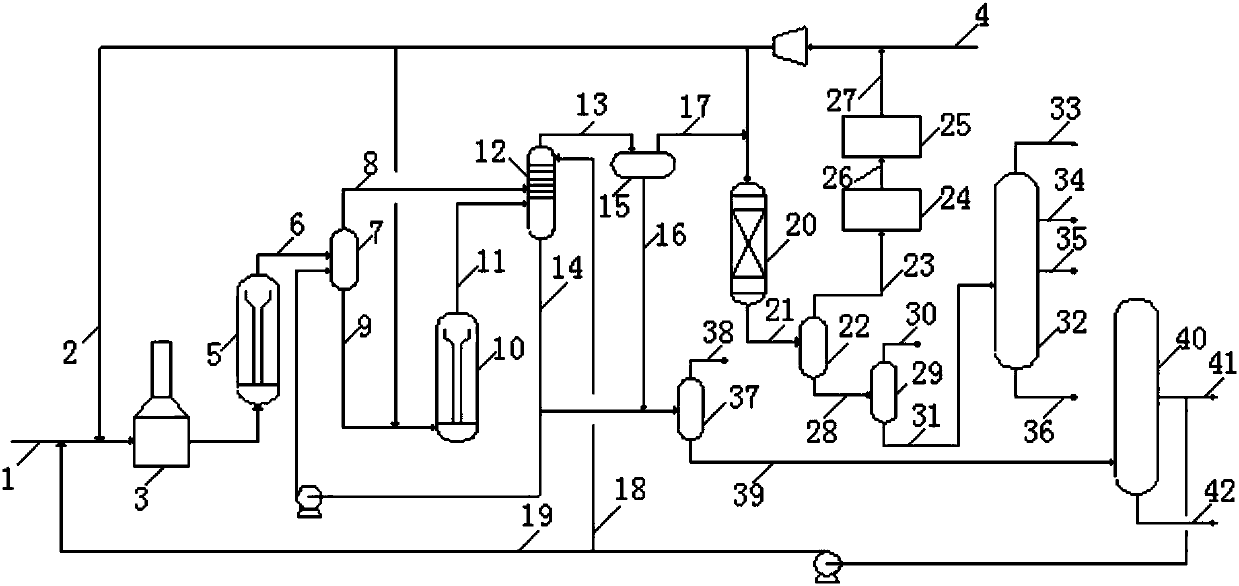

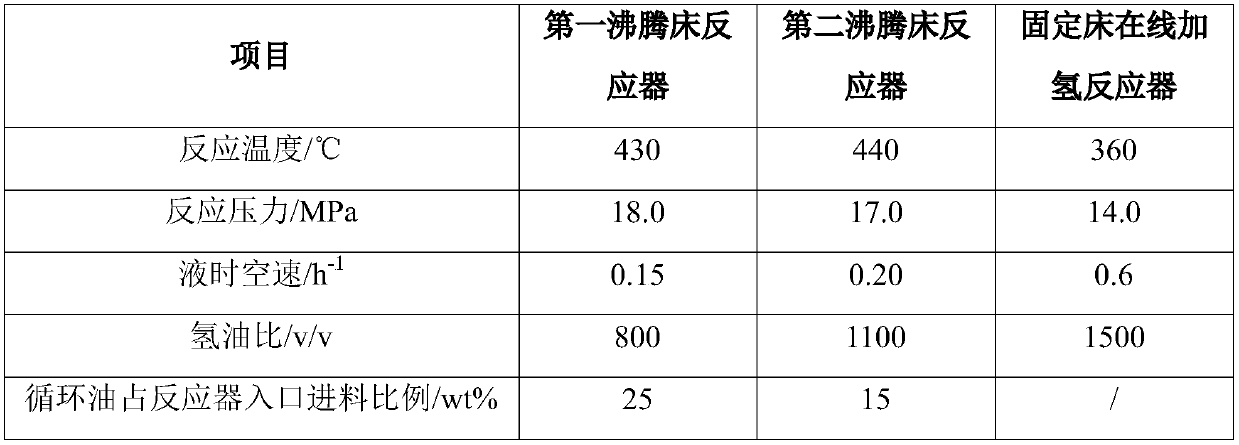

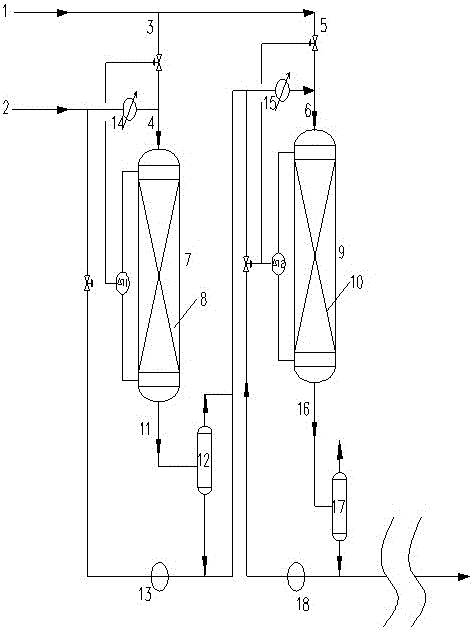

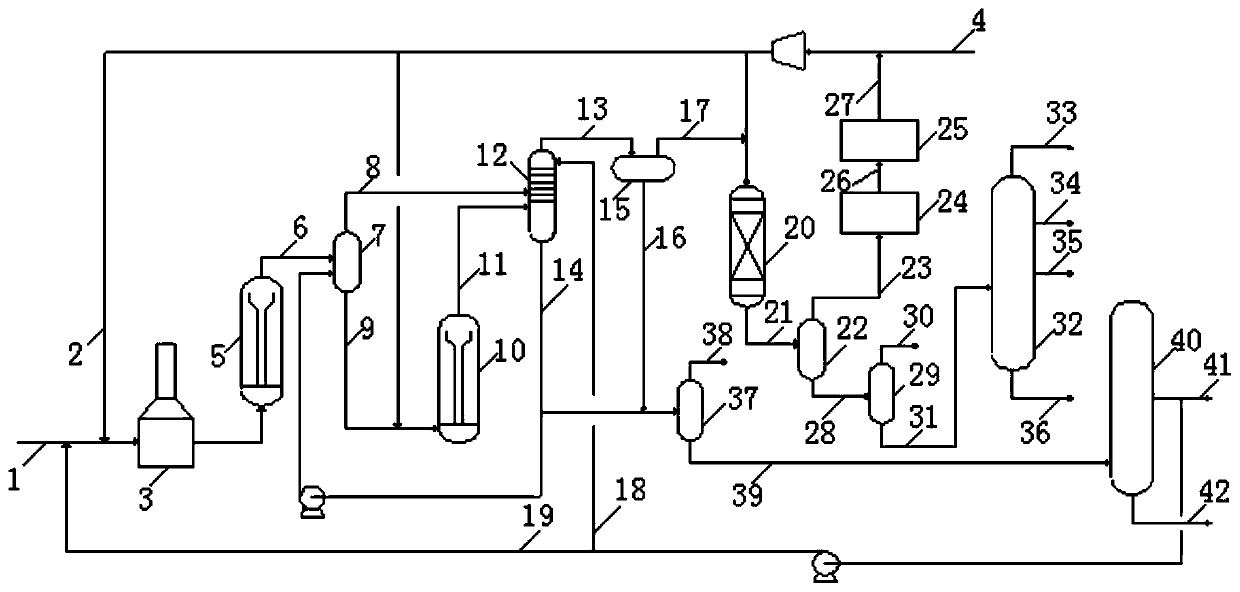

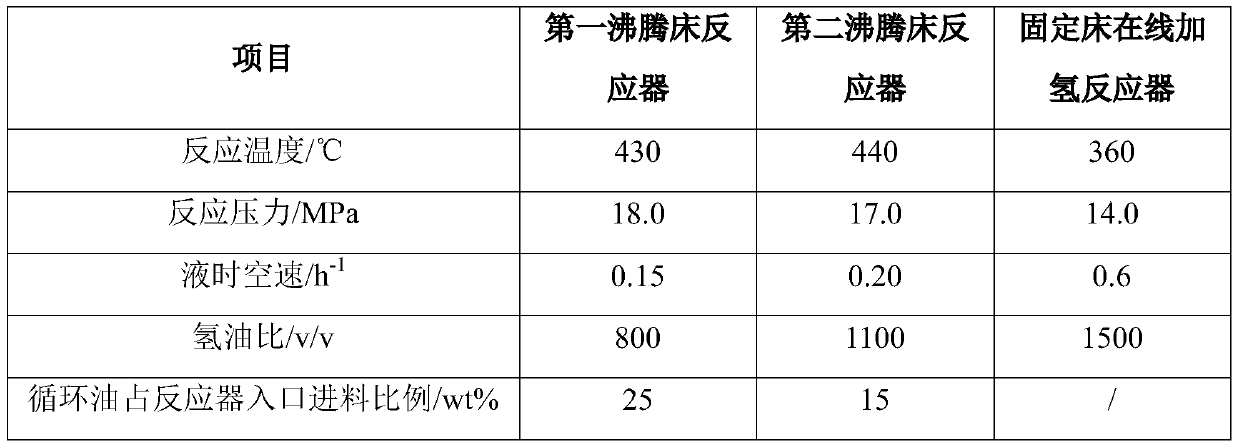

Method for combined hydrogenation of heavy oil

ActiveCN107815329AReduce lossesAvoid the disadvantages of complicated processTreatment with hydrotreatment processesWaxGas phase

The invention relates to a method for combined hydrogenation of heavy oil. The method adopts an online hydrogenation combined process of a boiling bed and a fixed bed, light oil obtained by hydrogenation of the boiling bed does not undergo the processes of pressure reduction and frictional distillation, light oil gas phase lower than 350 DEG C obtained by a warm high-pressure separator directly enters a fixed bed reactor for hydrogenation reaction, thus avoiding the defect of complex process caused by the procedure of firstly performing product pressure reduction and separation and then performing pressure-rising and temperature-rising hydrogenation of a conventional offline hydrogenation combined process, reducing the content of wax oil component in the light oil of the fixed bed reactor,and improving the selectivity of the hydrorefining reaction. In addition, the method also has the advantages of being high in light oil yield, small in catalyst consumption, reasonable in energy utilization, compact in process flow and low in device energy consumption.

Owner:SINOPEC ENG +1

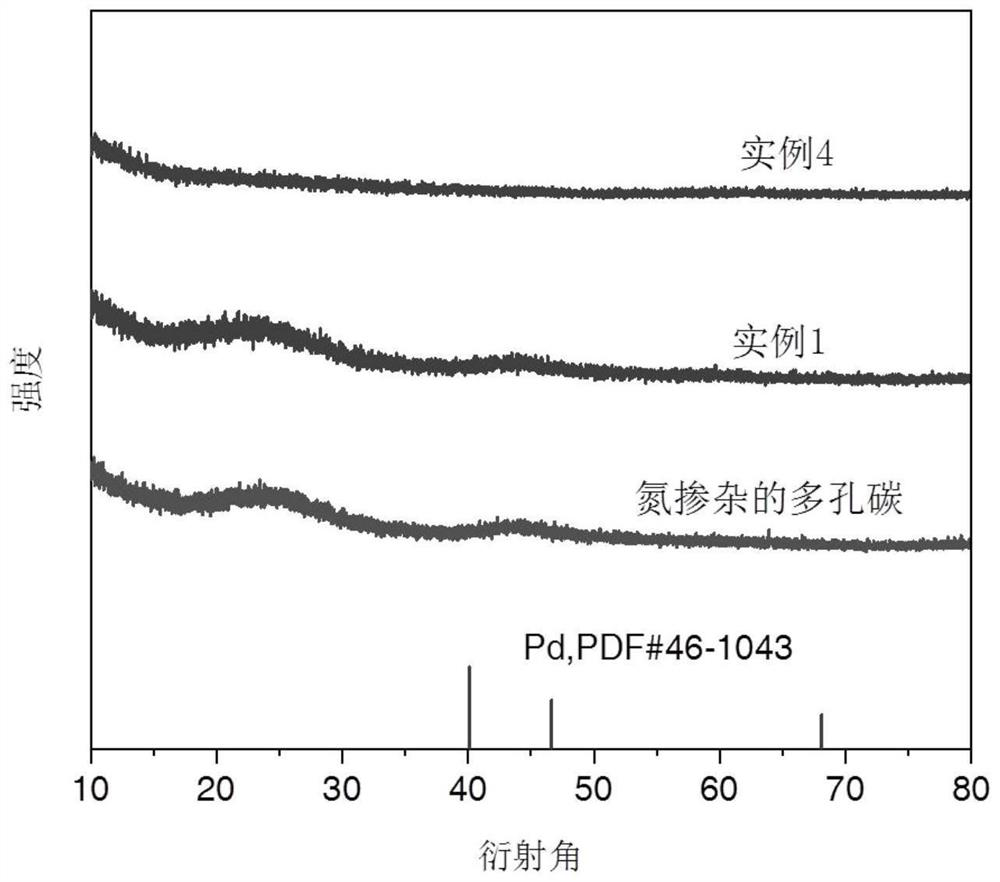

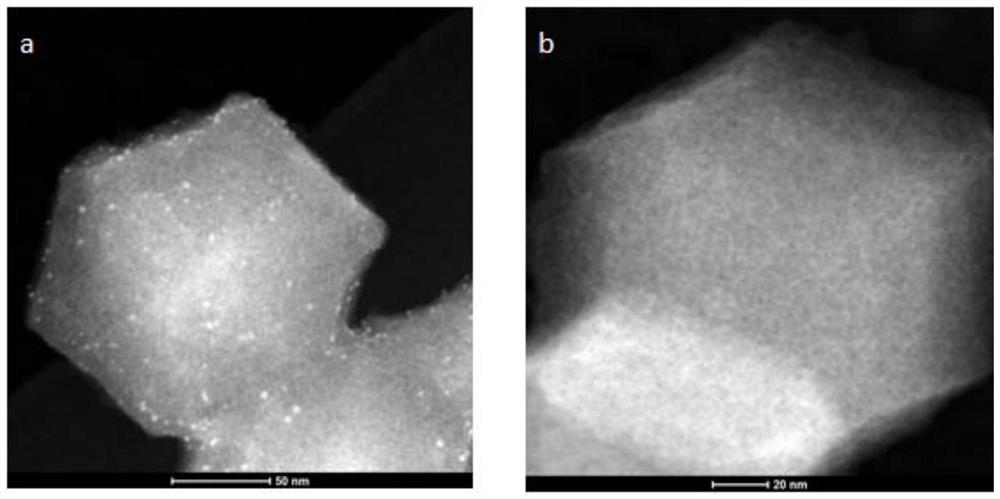

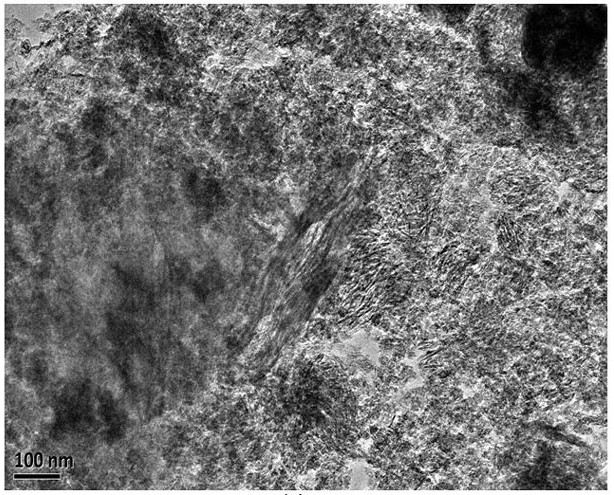

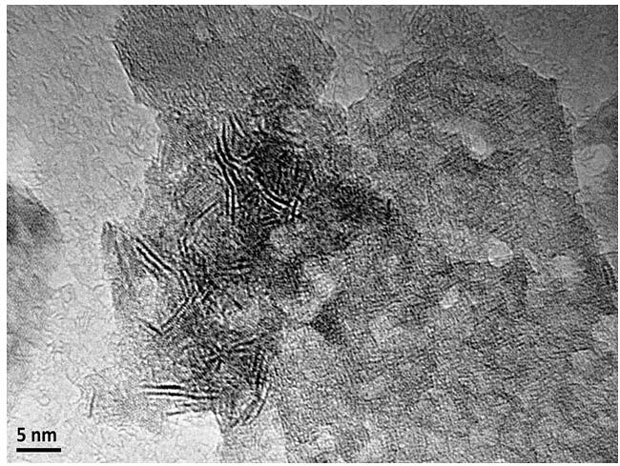

Preparation method and application of palladium metal cluster catalyst

ActiveCN114849753AHigh activityLow costPhysical/chemical process catalystsHydrocarbon by hydrogenationNano catalystPtru catalyst

The invention relates to the field of metal cluster catalysts, and discloses a preparation method and application of a palladium metal cluster catalyst, the method comprises the following steps: S1, preparing a zeolite imidazole framework material ZIF8 through zinc nitrate and 2-methylimidazole, and annealing and heating the ZIF8 in Ar atmosphere to obtain a nitrogen-doped porous carbon material; s2, preparing a [Pd3Cl (PPh2) 2 (PPh3) 3] < + > [SbF6] <-> crystal as a reaction precursor by adopting a ligand-regulated liquid phase reduction method; and S3, dispersing the nitrogen-doped porous carbon in dichloromethane, dissolving the reaction precursor in dichloromethane, dropwise adding into the mixture, stirring, centrifuging, drying and separating out a supported sample, and annealing and heating in an Ar atmosphere to obtain the supported palladium metal cluster catalyst. According to the invention, the palladium metal cluster nano-catalyst with uniform dispersion and consistent morphology is prepared by a two-step annealing method, and the obtained catalyst shows excellent activity and selectivity on phenylacetylene hydrogenation reaction.

Owner:UNIV OF SCI & TECH OF CHINA

Emergent shutdown method for hydrogenation device in production of hydrogen peroxide

ActiveCN105621366APromote circulationAvoid overhydrogenationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogenWorking fluid

The invention discloses an emergent shutdown method for a hydrogenation device in production of hydrogen peroxide. The method comprises the following steps: (1) arranging a system for emergent shutdown of hydrogenation in the hydrogenation device, and when operation parameters are abnormal, opening the system; (2) after the system is opened, and carrying out the following steps: a, completely stopping feeding of hydrogen gas; b, increasing the circulation volume of working fluid; c, when the outlet temperature of the hydrogenation device is reduced to 45 DEG C or below, opening a working fluid bypass valve, and closing a working fluid feeding valve; d, opening an aromatic hydrocarbon feeding valve, introducing low-temperature aromatic hydrocarbon, and subjecting a catalyst bed to washing; e, opening a nitrogen gas inlet valve, introducing nitrogen gas into the hydrogenation device, and carrying out aromatic hydrocarbon replacement; and f, introducing nitrogen gas, and subjecting the catalyst bed to blowing and purging; and (3) when the operation parameters return to normal levels, closing the system, and closing inlet and outlet pipelines of all materials at the same time so as to finish shutdown operation. The method provided by the invention is safe, stable and reliable, and is significantly favorable for protecting noble metal catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ionic liquid-modified loaded carbine-palladium catalyst and application thereof in acetylene hydrogenation reaction

ActiveCN109174184AGood choiceImprove conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon purification/separationPalladium catalystCarbene

The invention discloses an ionic liquid-modified loaded carbine-palladium catalyst and application thereof in acetylene hydrogenation reaction. The catalyst is prepared by the following steps: (1) dissolving ionic liquid A into a solvent, so as to obtain an ionic liquid solution; (2) adding potassium tert-butoxide or anhydrous sodium acetate powder, and stirring until solids are completely dissolved, so as to obtain a carbine solution; (3) adding a palladium precursor solution or into the carbine solution in a proportion, and stirring, so as to obtain a carbine-palladium-containing solution; (4) weighing a certain amount of the ironic liquid B, mixing the ironic liquid B with the carbine-palladium-containing solution, so as to obtain dipping liquid; and (5) uniformly pouring aluminum oxidecarriers into the dipping liquid until aluminum oxide is completely immersed and adequately dispersed, dipping the immersed carriers at the room temperature, and drying, so as to obtain the ionic liquid-modified loaded carbine-palladium catalyst. The catalyst presents the characteristics of high acetylene conversion rate and ethylene selectivity in the acetylene hydrogenation reaction.

Owner:ZHEJIANG UNIV OF TECH

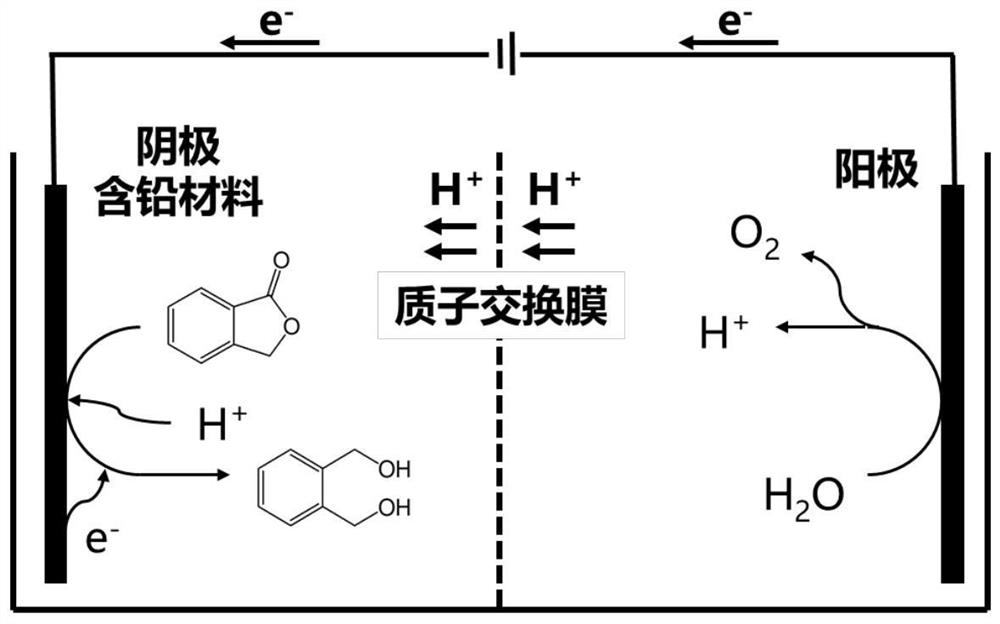

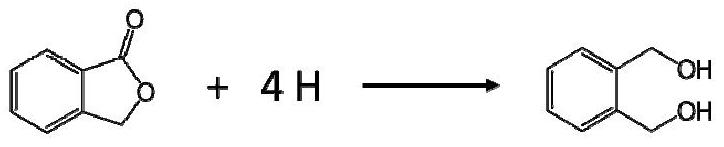

Electrochemical synthesis method for preparing o-benzenedimethanol from phthalide

ActiveCN114250481ASimple methodSimple processElectrolysis componentsElectrolytic organic productionChemical synthesisElectrolytic agent

The invention discloses an electrochemical synthesis method for preparing o-benzenedimethanol from phthalide, and belongs to the field of fine chemical engineering. According to the method, the phthalide is successfully converted into the o-phthalyl alcohol in an acidic electrolyte by taking lead-containing metal as an electrode material through an electrochemical method, and the selectivity of the o-phthalyl alcohol reaches 97%. The whole process does not need to add toxic organic solvent, does not need to input hydrogen externally, can perform reaction at low temperature and normal pressure, is mild in condition and simple in process, saves investment, and accords with the development direction of green chemical synthesis.

Owner:DALIAN UNIV OF TECH

Gasoline modification method

ActiveCN103059948BReduce cokingExtended operating cycleTreatment with hydrotreatment processesHydrodesulfurizationDistillation

The invention discloses a gasoline modification method. The method comprises: subjecting the gasoline light fraction fractionated from a catalytic cracking distillation tower lateral line to fixed bed oxidation deodorization, converting mercaptan into a disulfide, mixing the deodorized product with thermocatalytic diesel oil, subjecting the mixture to fractionation in a prefractionator so as to obtain light fraction and diesel oil fraction; carrying out a hydrogenation pretreatment on heavy fraction obtained from an FCC (fluid catalytic cracking) fractionating tower, removing unstable diene and mercaptan, then performing selective hydrodesulfurization through high activity / low activity combination, and mixing the desulfurization product with the deodorized light fraction so as to obtain a clean gasoline product. Compared with the prior art, the method disclosed in the invention can produce the clean gasoline product with a sulfur content of less than 10 micrograms / g and an octane number loss of not greater than 1.5 units. Meanwhile, the colloid generated by oxidation deodorization and the coking precursor generated by diene under a high temperature can be prevented from influencing normal operation of hydrogenation equipment, thus prolonging the equipment operating cycle. The method provided in the invention has the advantages of wide raw material adaptability and flexibility, mature technology, and high reliability.

Owner:CHINA PETROLEUM & CHEM CORP +1

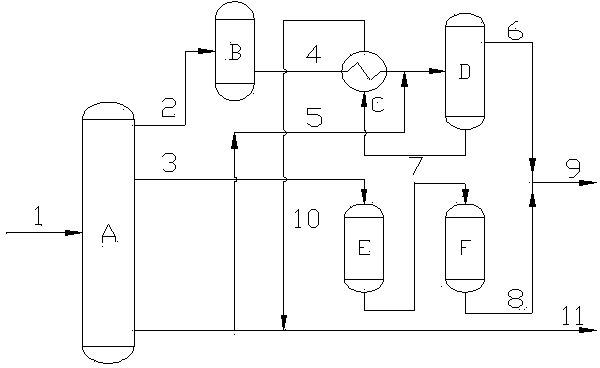

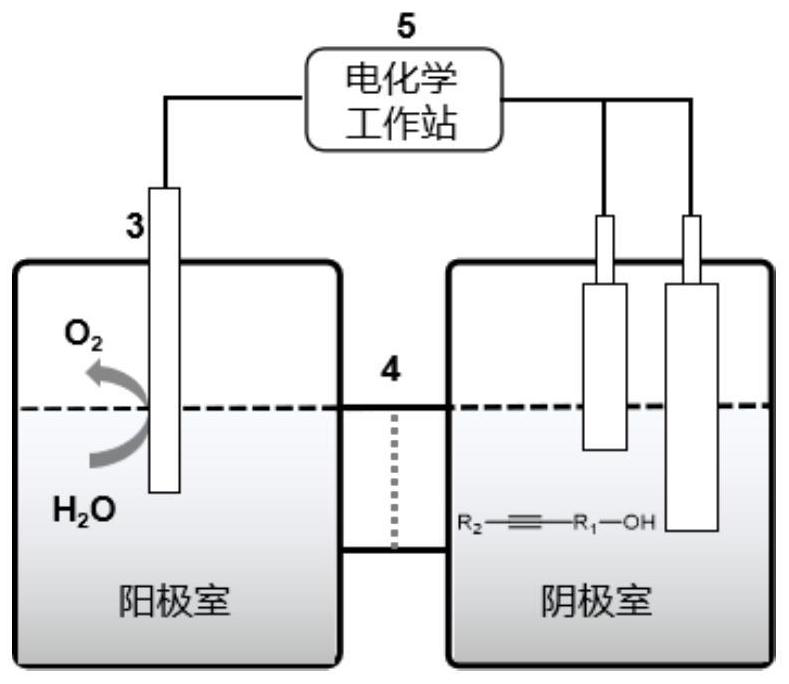

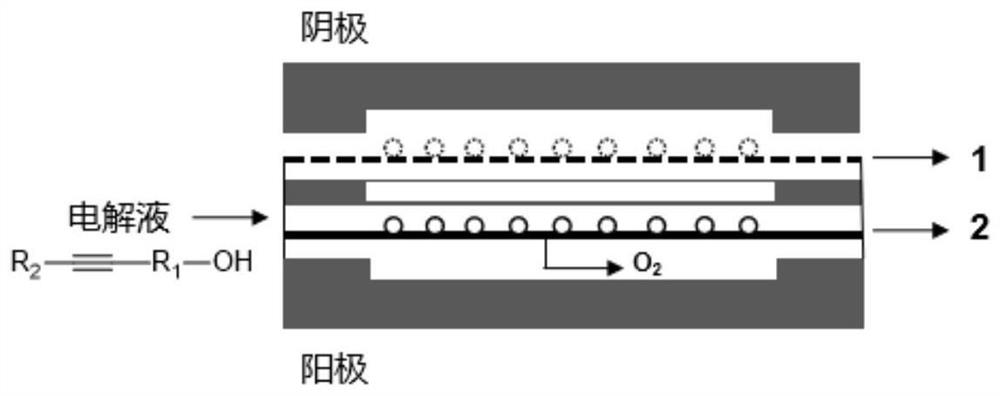

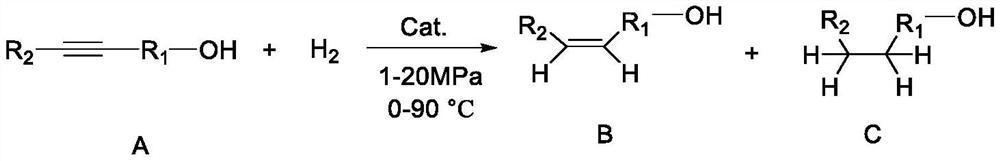

Method for preparing enol by electrocatalytic selective hydrogenation of alkynol

PendingCN114318373AReduce contact resistanceReduce consumptionElectrolytic organic productionElectrodesPtru catalystProcess engineering

The invention relates to a method for preparing enol by electrocatalytic selective hydrogenation of alkynol, which comprises but is not limited to terminal alkynol such as 2-methyl-3-butyne-2-ol, 1, 4-butynediol, methyl butynol, ethynyl cyclohexanol, dehydrolinalool and the like, non-terminal alkynol, cyclic alkynol, alkynodiol and the like. Different types of electrolytic tanks can be adopted; the contact resistance between a catalyst and an ion exchange membrane can be reduced by a preparation process of a membrane electrode in a flow type electrolytic tank; the split H-type electrolytic tank can control the mass transfer rate of alkynol selective hydrogenation. The method is an electro-catalysis mode which is green, safe, low in cost and high in efficiency, compared with a traditional thermal catalysis technology, the method can selectively reduce reactant alkynol into enol at the room temperature and normal pressure, water serves as a hydrogen source to replace flammable and explosive hydrogen, energy consumption and potential risks in the process can be greatly reduced, the requirement of green chemical engineering is met, and the method is suitable for industrial production. The method has great strategic significance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Gasoline selective hydrodesulfurization and olefin reduction catalyst and preparation method and application thereof

PendingCN113797938AReduce lossesReduce sulfur contentCatalyst activation/preparationHydrocarbon oils treatment productsPtru catalystHydrodesulfurization

The invention discloses a gasoline selective hydrodesulfurization and olefin reduction catalyst and a preparation method and application thereof. The catalyst comprises a carrier and an active metal component, wherein the carrier is an alumina-based carrier of which the surface is coated with graphene oxide. The method comprises the following steps of: (1) mixing graphene oxide with an alumina-based carrier, carrying out first microwave treatment, adding an alkaline solution, carrying out second microwave treatment, filtering, and drying to obtain an alumina-based carrier of which the surface is coated with graphene oxide; and (2) loading an active metal component onto the carrier obtained in the step (1), and drying to obtain the catalyst. The catalyst is used in a hydrogenation process for producing clean gasoline, and compared with a traditional hydrodesulfurization catalyst, the catalyst has higher hydrodesulfurization selectivity and less octane number loss.

Owner:CHINA PETROLEUM & CHEM CORP +1

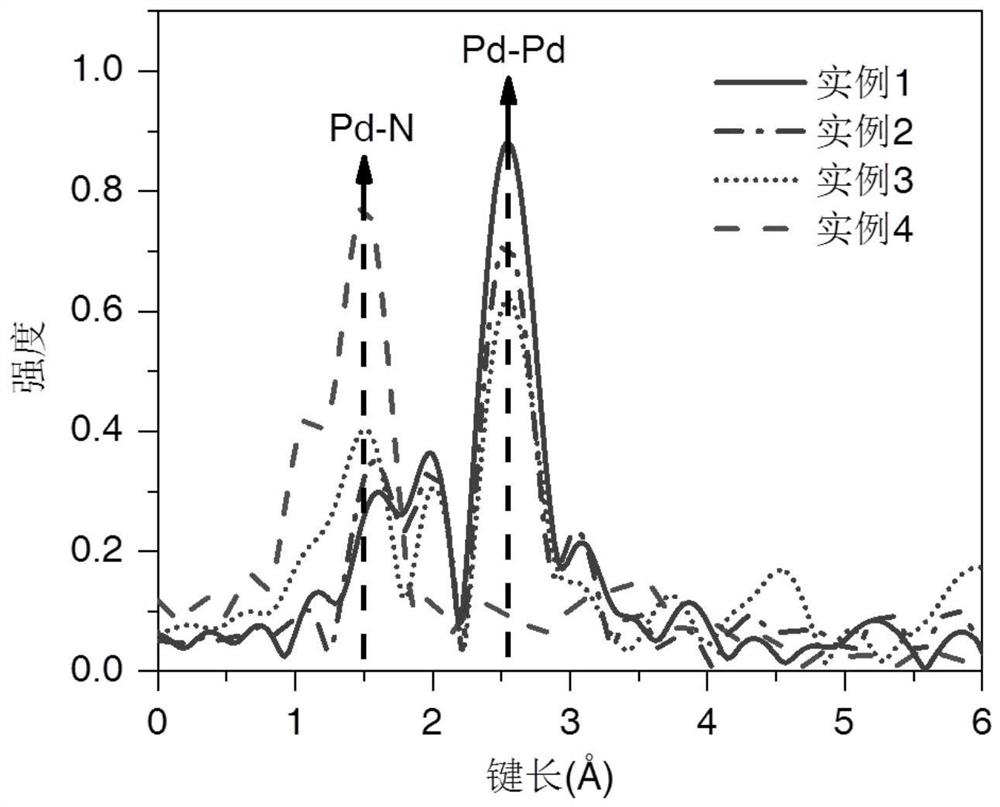

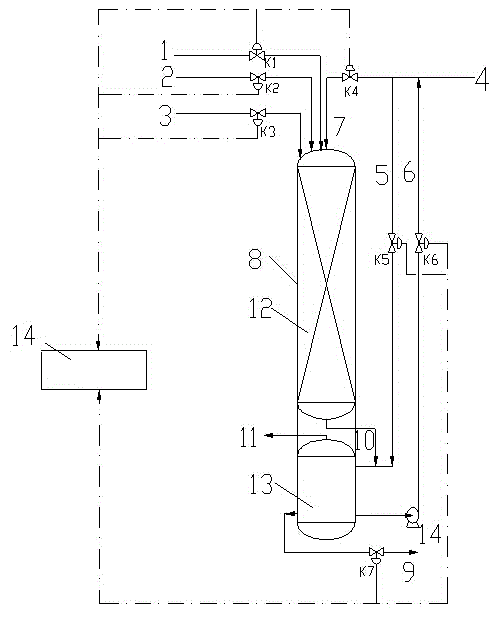

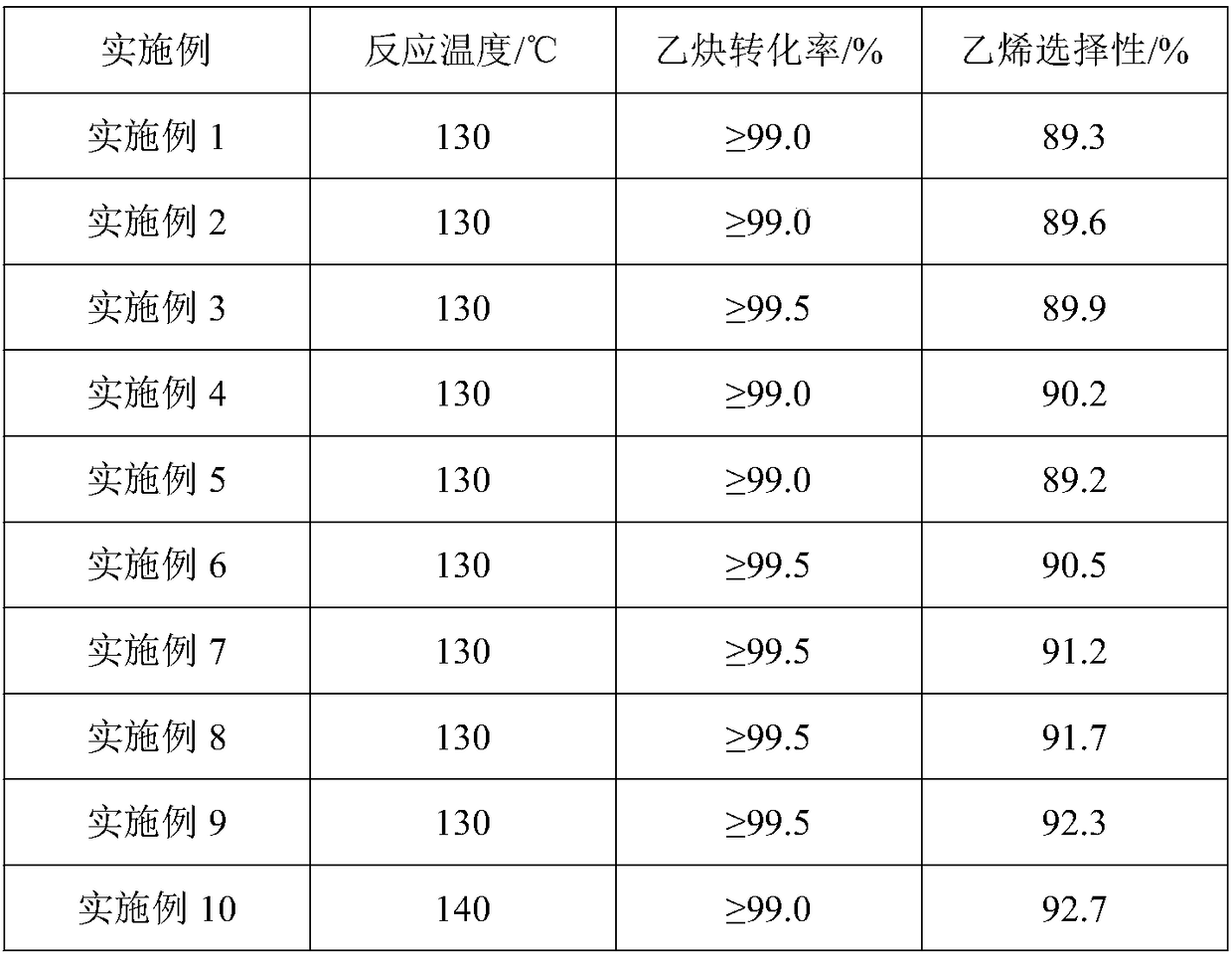

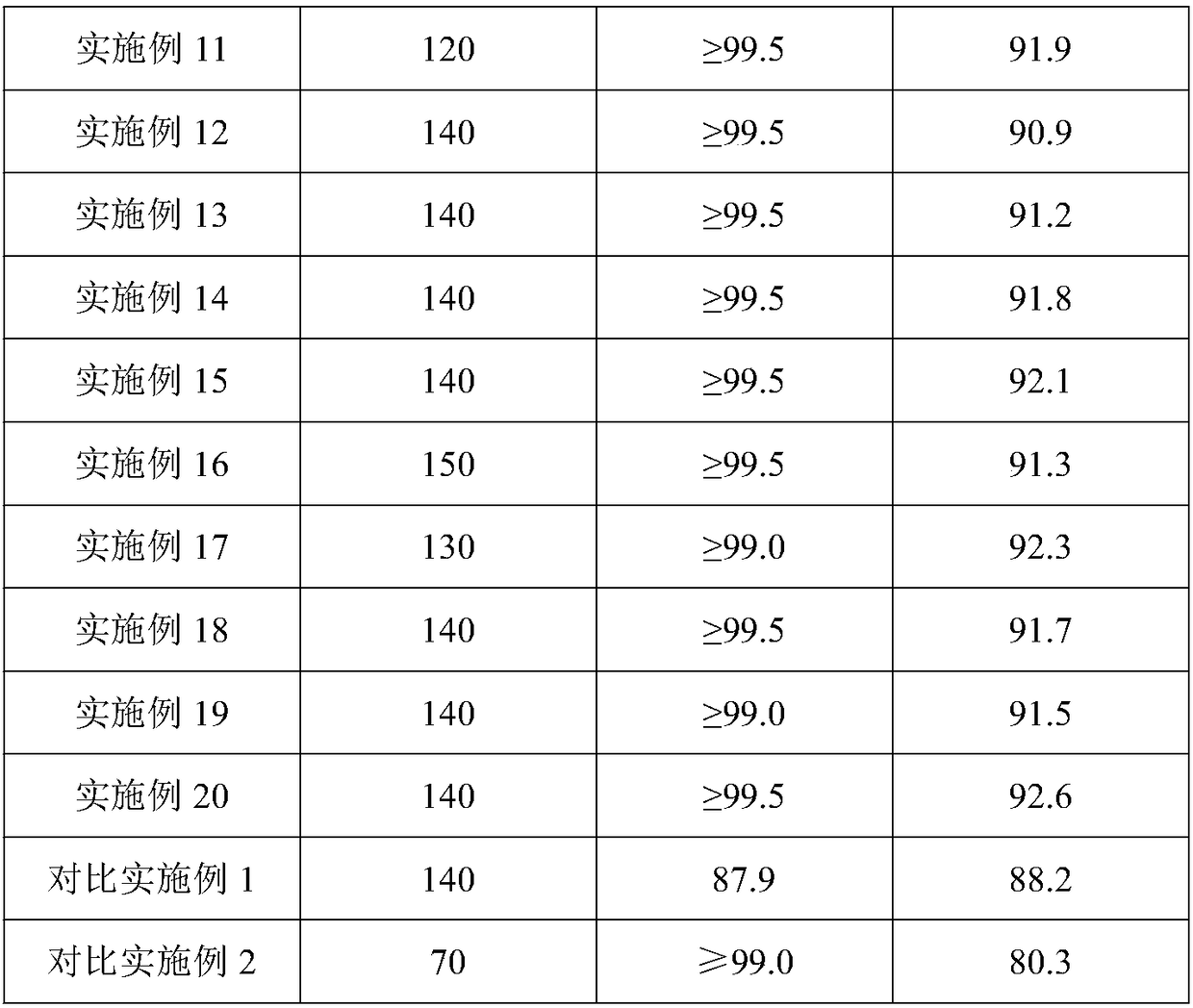

An In Situ Synthesis of PD-IL/Mesoporous Al 2 o 3 Catalyst methods and their applications

ActiveCN109092371BLarge specific surface areaGood dispersionHydrocarbon by hydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHydrogenation reaction

The invention discloses an in-situ method for synthesizing Pd-IL / Al 2 o 3 Methods and applications of mesoporous catalysts. The method comprises: (1) preparing an ethanol solution of P123; (2) dissolving concentrated nitric acid in absolute ethanol, then adding weighed aluminum isopropoxide, stirring vigorously so that the aluminum isopropoxide is completely dissolved, and dissolving the obtained solution Slowly drop into the ethanol solution of P123; (3) drop a certain concentration of palladium solution into the solution obtained in step (2), and stir vigorously at room temperature for 1-3 days; (4) after the stirring is completed, the solution is transferred to Evaporate the solvent in an oven to obtain a sponge-like sample; (5) put the sponge-like sample in a muffle furnace and bake it at 300-700°C for 3-6h to obtain the Pd / mesoporous Al 2 o 3 ; (6) in Pd / mesoporous Al 2 o 3 Ionic liquid loaded on the surface, that is, Pd-IL / mesoporous Al was prepared 2 o 3 catalyst. Pd-IL / mesoporous Al prepared by the present invention 2 o 3 The catalyst is applied in the selective hydrogenation reaction of acetylene, and exhibits excellent catalytic performance, wherein the conversion rate of acetylene is ≥99.0%, and the ethylene selectivity is ≥90%.

Owner:ZHEJIANG UNIV OF TECH

A hydrogenation process for producing hydrogen peroxide by anthraquinone method

ActiveCN104418308BAvoid overhydrogenationImprove quality levelPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogenation reactionAnthraquinone process

The invention discloses a hydrogenation technology for producing hydrogen peroxide by an anthraquinone process, which comprises the following steps: operating fluid and hydrogen-containing gas in the hydrogenation technology for producing hydrogen peroxide by the anthraquinone process are introduced in a reactor along flowing direction of materials in the reactor, a hydrogenation reaction is carried out on a bed layer of a catalyst, each strand of operating fluid corresponds a strand of hydrogen-containing gas, wherein hydrogen-containing gas is divided into 2-10 strands, the strand number of operating fluid is less than that of the hydrogen-containing gas, The last strand of the material long the flowing direction of the material is the hydrogen-containing gas. The technology can effectively avoid the excessive hydrogenation, increase hydrogen effect and prolong the usage life of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of novel sex pheromone component of hyphantria cunea

The invention belongs to the technical field of chemical production, and particularly relates to a novel method for synthesizing sex pheromone components of hyphantria cunea, and the sex pheromone components of hyphantria cunea comprise I [(3Z, 6Z, 9S, 10R)-9, 10-epoxy-3, 6-heneicosa diene ] and II [ (3Z, 6Z, 9S, 10R) -9, 10-epoxy-1, 3, 6-henesa triene ]. Carbon tetrabromide and triphenylphosphine are used to mildly perform bromination reaction on the key intermediate (2S, 3R) -2, 3-epoxy-1-tetradecanol (compound 1) , and the method is simple, convenient and high in yield; according to the invention,1, 4-heptadiyne and 1-heptene-3, 6-diyne are introduced into related structural fragments, so that the reaction steps are reduced, and the reaction yield is improved; and according to the method, the use of the Lingdeler palladium catalyst is abolished, and the P2-type nickel generated in situ by nickel acetate and sodium borohydride is used as the catalyst, so that the production cost is reduced, excessive hydrogenation of carbon-carbon triple bonds is prevented, the reaction is mild and controllable, and the yield is good.

Owner:南京沐森林业科技有限公司

A kind of hydrogenation process of producing hydrogen peroxide by anthraquinone method

ActiveCN104555935BPrevent deficienciesAvoid excessive hydrogenation reactionsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesGas phaseHydrogenation process

The invention discloses a hydrogenation process for producing a hydrogen peroxide by an anthraquinone method. The hydrogenation process comprises the following steps that: (1) two reactors are arranged in the hydrogenation process for producing the hydrogen peroxide by the anthraquinone method; a first current of fresh hydrogen and a working liquid serve as a feeding material I and perform hydrogenation in the first reactor; the reacted material is subjected to gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the first reactor; the rest of the liquid phase is reasonably optimized and modulated; the phenomenon that the reaction hydrogen is deficient or excessive is avoided; the hydrogenation completeness is realized; the liquid phase and the gas phase are mixed to serve as feeding material II and enter the second reactor; (2) a second current of fresh hydrogen and the feeding material II perform the hydrogenation in the second reactor; the reacted material is subjected to the gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the second reactor, and the rest of the liquid phase enters an oxidation process. According to the process disclosed by the invention, a hydrogenation process is optimized, and meanwhile, side effects are reduced, so that the hydrogenation is more uniform, and the service life of a catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for synthesizing diphenylmethanol by catalytic hydrogenation of benzophenone

ActiveCN109320398BImprove hydrogenation activityInhibit side effectsOrganic compound preparationHydroxy compound preparationSodium acetateActivated carbon

The invention discloses a method for synthesizing benzphenyl alcohol by catalytic hydrogenation of benzophenone. The method is as follows: the method adopts a supported multi-component catalyst and adds a protective agent in the reaction system; the supported The multi-component catalyst is Pd-Cu-Sn / C, the carrier is activated carbon, the active component is Pd, and the additives are Cu and Sn, wherein the loading of Pd is 1-10wt%, and the loading of Cu is 1-5wt %, the load of Sn is 1-5wt%; the protective agent is sodium acetate. The method of the invention can improve the conversion rate of benzophenone and the selectivity of benzhydryl alcohol.

Owner:ZHEJIANG UNIV OF TECH

A method for combined hydrogenation of heavy oil

ActiveCN107815329BReduce lossesAvoid the disadvantages of complicated processTreatment with hydrotreatment processesWaxHydrogenation reaction

The invention relates to a method for combined hydrogenation of heavy oil. The method adopts an online hydrogenation combined process of a boiling bed and a fixed bed, light oil obtained by hydrogenation of the boiling bed does not undergo the processes of pressure reduction and frictional distillation, light oil gas phase lower than 350 DEG C obtained by a warm high-pressure separator directly enters a fixed bed reactor for hydrogenation reaction, thus avoiding the defect of complex process caused by the procedure of firstly performing product pressure reduction and separation and then performing pressure-rising and temperature-rising hydrogenation of a conventional offline hydrogenation combined process, reducing the content of wax oil component in the light oil of the fixed bed reactor,and improving the selectivity of the hydrorefining reaction. In addition, the method also has the advantages of being high in light oil yield, small in catalyst consumption, reasonable in energy utilization, compact in process flow and low in device energy consumption.

Owner:SINOPEC ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com