An In Situ Synthesis of PD-IL/Mesoporous Al 2 o 3 Catalyst methods and their applications

An in-situ synthesis, catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalyst, carbon compound catalyst, physical/chemical process catalyst, etc., can solve the problem of low ethylene selectivity, achieve large specific surface area, The effect of improving selectivity and superior catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

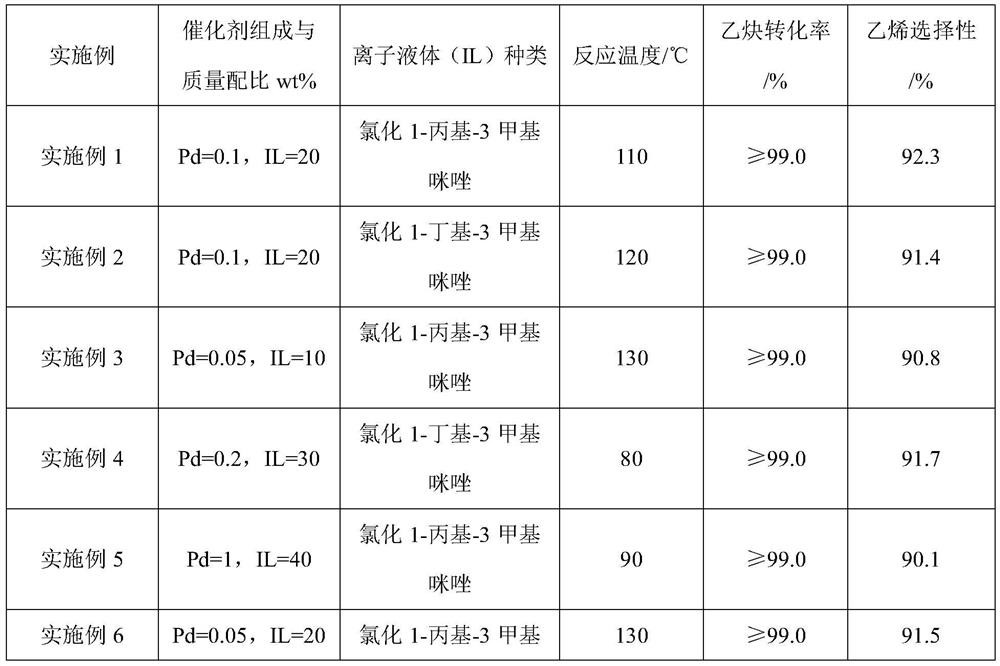

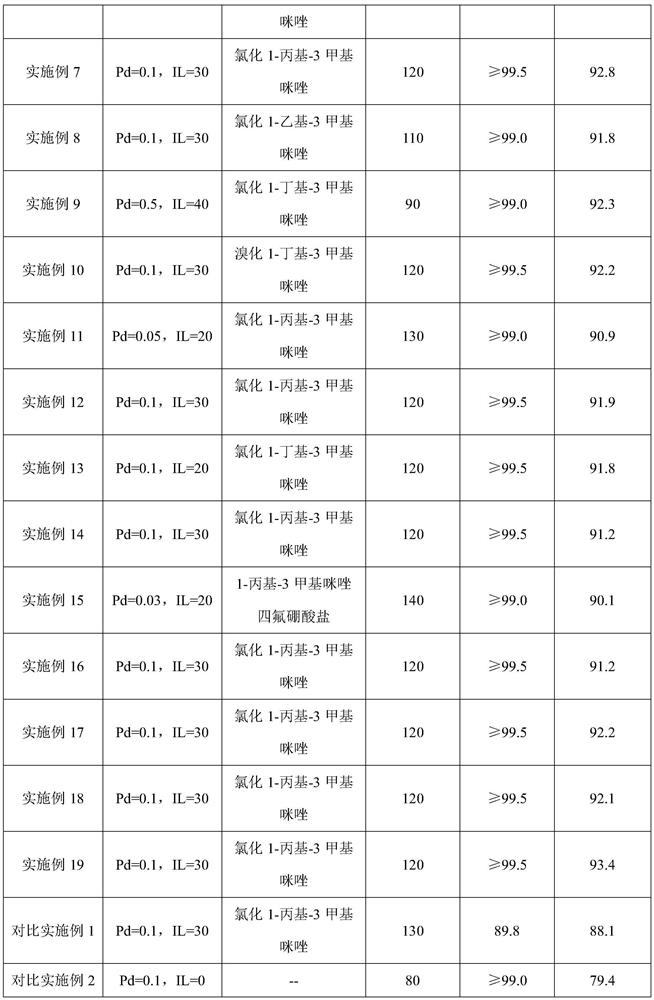

Embodiment 1-5

[0028] Weigh 2.1 g of P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, Mr=5800), dissolve it in 25 mL of absolute ethanol, and stir vigorously to make it evenly mixed. Measure 3 mL of 67% concentrated nitric acid and dissolve it in 25 mL of absolute ethanol, then add 4.2 g of aluminum isopropoxide, and stir vigorously to completely dissolve the aluminum isopropoxide. After the dissolution was complete, the resulting solution was slowly dropped into the ethanol solution containing P123. Add a certain amount of PdCl dropwise under vigorous stirring 2 Hydrochloric acid solution (see Table 1), the large beaker was sealed with PE film, and stirred vigorously at room temperature for 2 days. After the stirring was completed, the solution was transferred to an oven at a temperature of 60° C., and the ethanol solvent was evaporated in the oven for 3 days. The spongy sample obtained by evaporation to dryness was put into a muffle furnace and calcined...

Embodiment 6-9

[0031] Weigh 2.1 g of P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, Mr=5800), dissolve it in 25 mL of absolute ethanol, and stir vigorously to make it evenly mixed. Measure 3 mL of 67% concentrated nitric acid and dissolve it in 25 mL of absolute ethanol, then add 4.2 g of aluminum isopropoxide, and stir vigorously to completely dissolve the aluminum isopropoxide. After the dissolution was complete, the resulting solution was slowly dropped into the ethanol solution containing P123. A certain amount of tetraammine palladium nitrate aqueous solution (see Table 1) was added dropwise under vigorous stirring, the large beaker was sealed with PE film, and vigorously stirred at room temperature for 2 days. After the stirring was completed, the solution was transferred to an oven at a temperature of 60° C., and the ethanol solvent was evaporated in the oven for 3 days. The spongy sample obtained by evaporation to dryness was put into a muffle fu...

Embodiment 10-12

[0034]Weigh 3 g of P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, Mr=5800), dissolve it in 25 mL of absolute ethanol, and stir vigorously to make it evenly mixed. Measure 5.0 mL of 67% concentrated nitric acid and dissolve it in 25 mL of absolute ethanol, then add 4.08 g of aluminum isopropoxide, and stir vigorously to completely dissolve the aluminum isopropoxide. After the dissolution was complete, the resulting solution was slowly dropped into the ethanol solution containing P123. A certain amount of tetraammine palladium nitrate aqueous solution (see Table 1) was added dropwise under vigorous stirring, the large beaker was sealed with PE film, and vigorously stirred at room temperature for 2 days. After the stirring was completed, the solution was transferred to an oven at a temperature of 60° C., and the ethanol solvent was evaporated in the oven for 3 days. The spongy sample obtained by evaporation to dryness was put into a muffle fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com