Preparation method and application of palladium metal cluster catalyst

A metal cluster and catalyst technology, which is applied in the field of preparation of palladium metal cluster catalyst, can solve the problems of insufficient catalyst stability, need to improve selectivity, complicated catalyst preparation, etc., and achieves avoiding overhydrogenation phenomenon, excellent activity and selectivity. , the appearance of the same effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

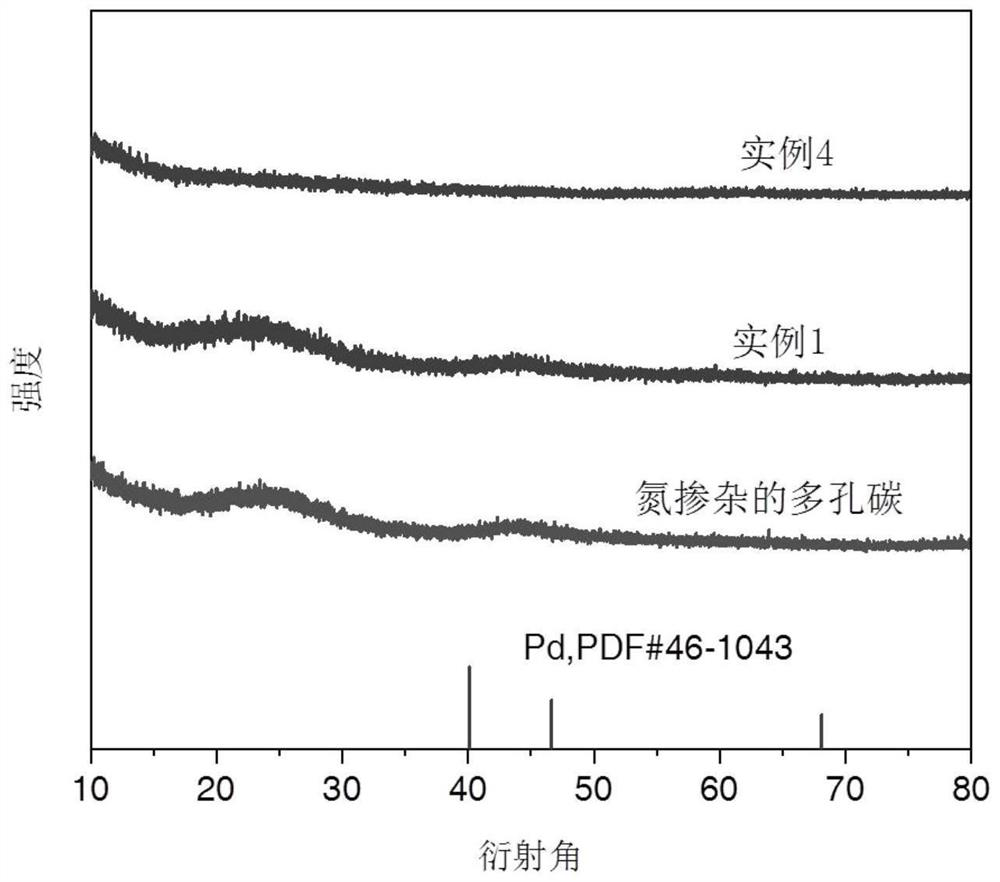

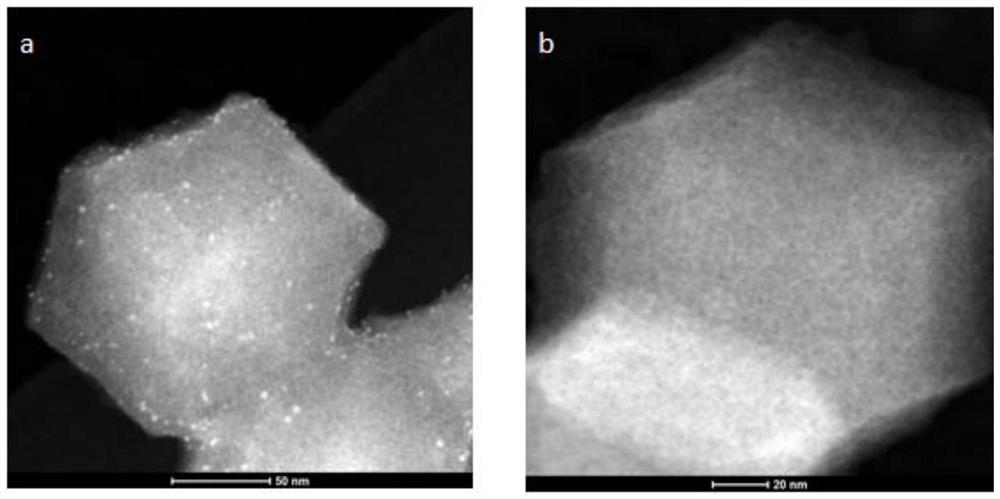

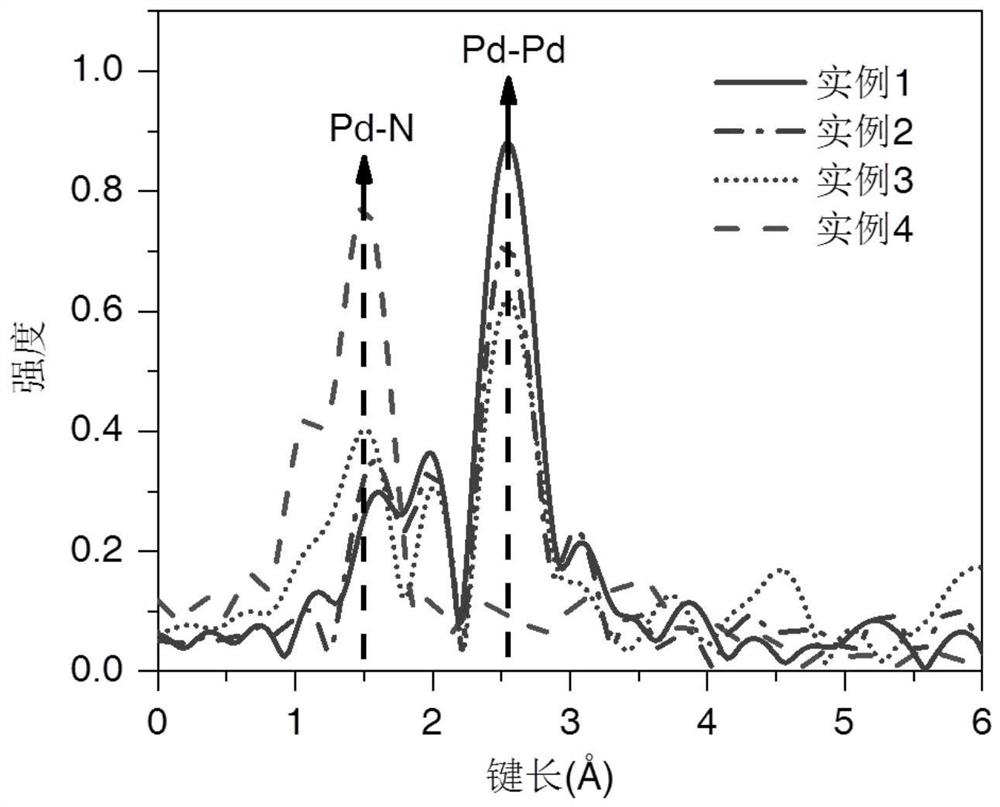

[0026] 3g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 50 mL of methanol, then added to 100 mL of pre-prepared methanol solution containing 6.5 g of 2-methylimidazole, and stirred vigorously for 12 h at room temperature; the obtained precipitate was centrifuged, washed with methanol three times, and vacuum-dried at 65 °C overnight to obtain Zeolitic imidazole framework material ZIF8; then put the obtained ZIF8 in a ceramic boat, annealed at 1050 °C for 2 h in an Ar atmosphere; after the temperature dropped to room temperature, the obtained nitrogen-doped porous carbon was stored for later use.

[0027] 1.42g PdCl 2 Dissolve in aqueous hydrochloric acid containing 16 mmol of HCl and dilute the solution to 10 mL. 0.6 mL of the above solution was added to 10 mL of tetrahydrofuran, followed by 0.313 g of triphenylphosphine; after vigorous stirring for 10 min, 5 mL of an ethanol solution containing 0.08 g of sodium borohydride was added to the mixture, followed by vigorous stirring for ...

Embodiment 2

[0030] 3g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 50 mL of methanol, then added to 100 mL of pre-prepared methanol solution containing 6.5 g of 2-methylimidazole, and vigorously stirred at room temperature for 24 h; the obtained precipitate was centrifuged, washed with methanol three times, and vacuum-dried at 60 °C overnight to obtain Zeolitic imidazole framework material ZIF8; then put the obtained ZIF8 in a ceramic boat, annealed at 1000 °C for 3 h in an Ar atmosphere; after the temperature dropped to room temperature, the obtained nitrogen-doped porous carbon was stored for later use.

[0031] 1.42g PdCl 2 Dissolve in aqueous hydrochloric acid containing 16 mmol of HCl and dilute the solution to 10 mL. 0.6 mL of the above solution was added to 10 mL of tetrahydrofuran, followed by 0.313 g of triphenylphosphine; after vigorous stirring for 8 min, 5 mL of an ethanol solution containing 0.08 g of sodium borohydride was added to the mixture, followed by vigorous stirring for 6...

Embodiment 3

[0034] 3g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 50 mL of methanol, then added to 100 mL of pre-prepared methanol solution containing 6.5 g of 2-methylimidazole, and stirred vigorously for 36 h at room temperature; the obtained precipitate was centrifuged, washed with methanol three times, and vacuum-dried at 65 °C overnight to obtain Zeolitic imidazole framework material ZIF8; then put the obtained ZIF8 into a ceramic boat, and anneal at 950 °C for 4 h in an Ar atmosphere. After the temperature dropped to room temperature, the obtained nitrogen-doped porous carbon was stored for later use.

[0035] 1.42g PdCl 2 Dissolve in aqueous hydrochloric acid containing 16 mmol of HCl and dilute the solution to 10 mL. 0.6 mL of the above solution was added to 10 mL of tetrahydrofuran, followed by 0.313 g of triphenylphosphine; after vigorous stirring for 6 min, 5 mL of an ethanol solution containing 0.08 g of sodium borohydride was added to the mixture, followed by vigorous stirring f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com