Gasoline selective hydrodesulfurization and olefin reduction catalyst and preparation method and application thereof

An olefin catalyst and hydrodesulfurization technology are applied in low olefin gasoline products to produce low sulfur fields to achieve the effects of improving selectivity, improving and reducing the loss of octane number.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The gasoline selective hydrodesulfurization and olefin reduction catalyst prepared in this example is designated as GDS-1.

[0046] Preparation of alumina-based carrier: Weigh 1000g pseudo-thin water aluminum hydroxide powder (Al 2 o 3 Dry basis content is 78wt%), adding Al 2 o 3 5wt% squid powder extrusion aid on a dry basis, 200mL of a 10% nitric acid aqueous solution, mixed and rolled to form a plastic powder, and a cylindrical strip with a diameter of 1.5mm was prepared with an extruder, and dried at 120°C 8 hours, calcination at 520°C for 5 hours to prepare an alumina-based carrier;

[0047] Preparation of alumina-based carrier covered with graphene oxide on the surface: Weigh 0.4g graphene oxide (GO) and 50g alumina-based carrier into a beaker, put it into a microwave oven for 700W microwave treatment for 1.0h, then add 94mL mass The KOH solution with a concentration of 10% continued to be treated with 600W microwave for 2.0h, taken out and filtered, and dried...

Embodiment 2

[0052] The gasoline selective hydrodesulfurization and olefin reduction catalyst prepared in this example is designated as GDS-2.

[0053] Preparation of alumina-based carrier: the same as in Example 1;

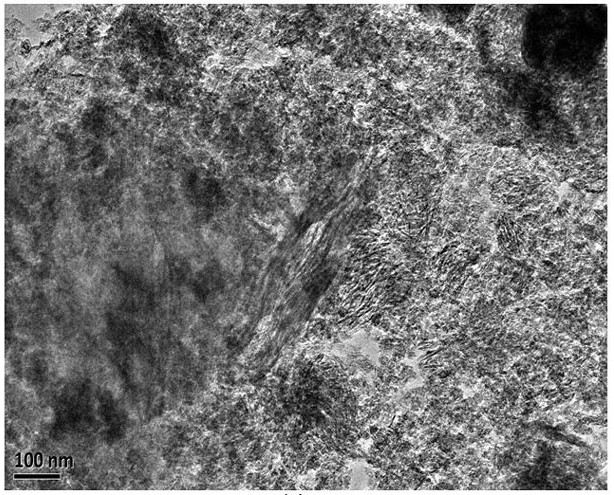

[0054] Preparation of alumina-based support covered with graphene oxide: Weigh 1.0g graphene oxide (GO) and 50g Al 2 o 3 Add the carrier into a beaker, put it into a microwave oven for 700W microwave treatment for 1.0h, then add 125mL of KOH solution with a mass concentration of 20% and continue 600W microwave treatment for 4.0h, take it out and filter, and dry at 140°C for 8 hours to obtain a surface-coated There is an alumina-based carrier of graphene oxide, and its TEM image is shown in image 3 ;

[0055] Catalyst preparation: MoO on catalyst 3 The content is 12.0wt%, and the CoO content is 3.5wt%. Take quantitative molybdenum oxide and basic cobalt carbonate, add deionized water, and make 60mL impregnation solution. Heat to 80°C, add 20mL of concentrated ammonia wat...

Embodiment 3

[0059] The gasoline selective hydrodesulfurization and olefin reduction catalyst prepared in this example is designated as GDS-3.

[0060] Preparation of alumina-based carrier: the same as in Example 1;

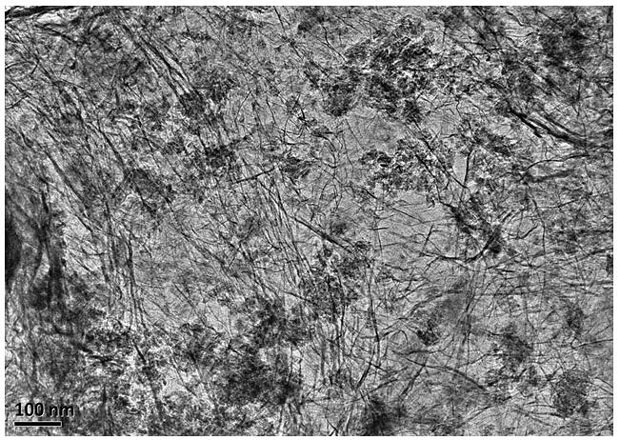

[0061] Preparation of alumina-based carrier covered with graphene oxide: Weigh 3.0g graphene oxide (GO) and 50g Al 2 o 3 Add the carrier into the beaker, put it into a microwave oven and treat it with 700W microwave for 1.0h, then add 150mL of KOH solution with a mass concentration of 20% to continue the microwave treatment at 600W for 4h, take it out and filter it, and dry it at 140°C for 8 hours to obtain a surface-coated Alumina-based support for graphene oxide, its TEM image is shown in Figure 5 ;

[0062] Catalyst preparation: same as Example 2, recorded as GDS-3 catalyst.

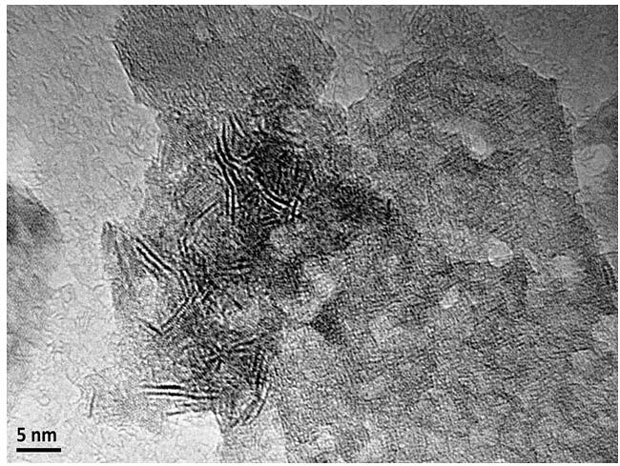

[0063] The properties of the GDS-3 catalyst are shown in Table 1, and the TEM image of the Co-Mo-S active phase crystallography of the GDS-3 catalyst after presulfurization is shown in Table 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com