Selective hydrogenation catalyst and application thereof and hydrogenation process of C-2 fraction in production of ethylene by steam cracking

A technology of selective hydrogenation and hydrogenation catalysis, which is applied in the direction of catalysts, hydrogenation hydrocarbons, carbon compound catalysts, etc., can solve the problems of low green oil amount and unutilized green oil resources, so as to avoid excessive hydrogenation and ensure hydrogenation The effect of hydrogen selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0037] According to a specific embodiment of the present invention, the catalyst carrier is prepared by a method comprising the following steps:

[0038] 1) Using an equal-volume impregnation method, mixing the phosphoric acid solution and the powder of the porous inorganic oxide carrier, followed by drying, molding, and roasting to obtain a solid;

[0039] 2) Mixing the solid matter with an organic solution of ethylene glycol antimony, followed by drying and hydrolysis to obtain the catalyst carrier.

[0040] In step 1), the impregnation can be performed at room temperature.

[0041] In step 2), the molding can be carried out on an extruder.

[0042] In the organic solution of ethylene glycol antimony, non-limiting examples of organic solvents include: one or more of methanol, ethanol, ethylene glycol, propylene glycol, isopropanol, glycerol, formic acid, acetic acid, acetone . Preferably, the solvent is ethanol and / or ethylene glycol.

[0043] The hydrolysis conditions m...

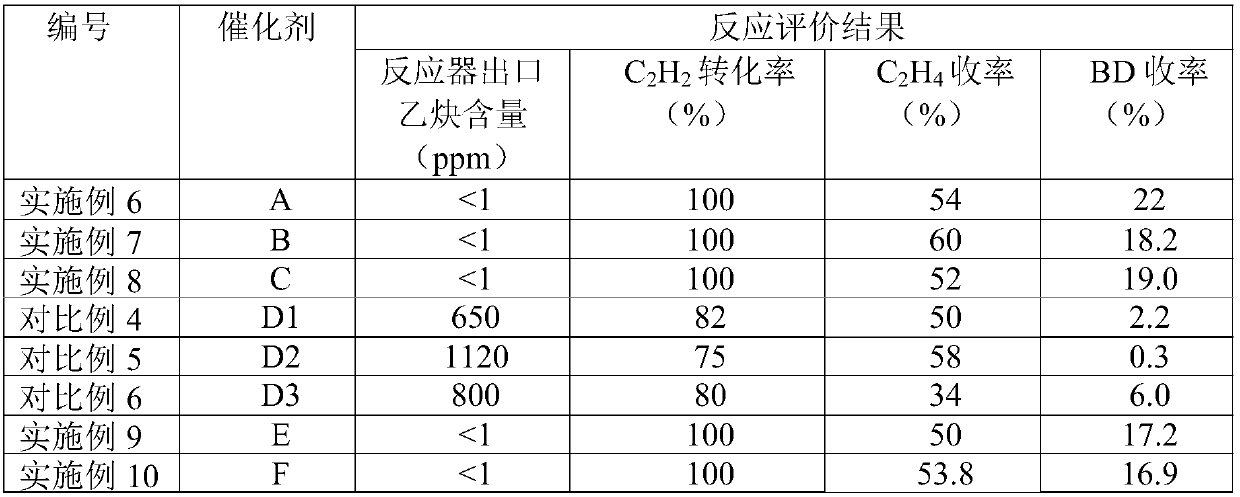

Embodiment 1

[0070] (1) Preparation of catalyst carrier

[0071] Put the weighed alumina powder in a beaker, impregnate the alumina powder with an equal volume of 1mol / L phosphoric acid solution, then dry it at 120°C for 12 hours, and then shape it in an extruder, at 400°C Roasted for 6 hours to obtain the diameter Strip-shaped solids with a length of 1-3mm.

[0072] Spray 1 mol / L ethylene glycol antimony solution in absolute ethanol on the bar-shaped solid, then dry it in an oven at 120°C, and then treat it with steam at 90°C for 6 hours for hydrolysis to obtain the carrier PS- al 2 o 3 , the amount of the above-mentioned raw materials makes the content of P in the catalyst 0.5wt%, and the content of Sb is 0.5wt%.

[0073] (2) load

[0074] Using the equal volume impregnation method, the 1mol / L palladium nitrate aqueous solution and the above-mentioned carrier PS-Al 2 o 3 Mix, load 0.01wt% palladium, then dry at 120°C for 4 hours, then bake at 500°C for 4 hours; then use equal volum...

Embodiment 2

[0076] Prepare the selective hydrogenation catalyst according to the method of Example 1, the difference is that the amount of silver nitrate impregnating solution is adjusted so that the loading of Ag is 0.03wt%, so as to obtain 0.01Pd0.03Ag / PS-Al 2 o 3 Catalyst, denoted as B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com